Rice bran dietary fiber fine dried noodles and processing method of rice bran dietary fiber fine dried noodles

A technology of dietary fiber and processing method, which is applied in the field of rice bran dietary fiber noodles and its processing, can solve problems such as exploration, and achieve the effects of promoting extension, good health care and preventing constipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

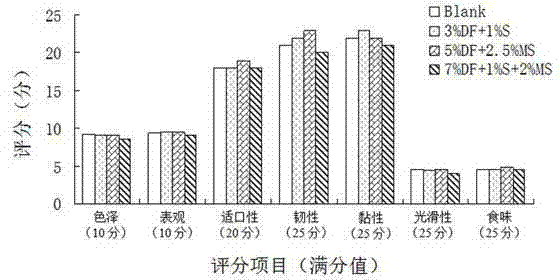

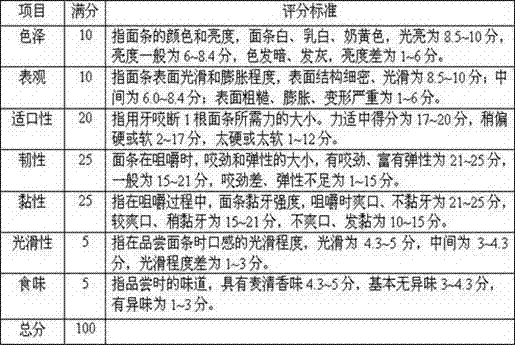

[0020] Mix 3kg of rice bran dietary fiber and 1kg of cassava starch in a dry powder state with 100kg of wheat flour to form a raw material powder, dissolve 2kg of salt in 36kg of drinking water and add it to the raw material powder for mechanical kneading operation. After the completion, several times of mechanical pressing, strip cutting, strip hanging, mechanical drying, surface cutting, finished product inspection and packaging operations are carried out in sequence. The total sensory evaluation score of the blank dried noodle sample without rice bran dietary fiber is 89 points, and the total sensory evaluation score of this batch of rice bran dietary fiber dried noodles is 91 points. The results of each score are as follows: figure 1 As shown in "3%DF+1%S" (the sensory evaluation criteria of dried noodles are shown in Table 1), it can be seen that the dried noodle product has good color, appearance, palatability, toughness, smoothness and taste, and Has very good viscosity...

Embodiment 2

[0022] Mix 500g of rice bran dietary fiber through a 100-mesh sieve and 250g of cassava pregelatinized starch in a dry powder state with 10kg of wheat flour to form a raw material powder. Dissolve 250g of table salt in 4kg of drinking water and add it to the raw material powder for mechanical kneading. , After the dough is finished, carry out several times of mechanical pressing, strip cutting, hanging strips, drying at room temperature, cutting noodles, finished product inspection and packaging operations in sequence. The total sensory evaluation score of the blank dried noodle sample without rice bran dietary fiber is 89 points, and the total sensory evaluation score of this batch of rice bran dietary fiber dried noodles is 92 points. The scoring results are as follows: figure 1 As shown in "5%DF+2.5%MS" (the sensory evaluation criteria of dried noodles are shown in Table 1), it can be seen that the dried noodle product has good color, appearance and viscosity, and has good p...

Embodiment 3

[0024] Mix 35g of rice bran dietary fiber through a 120-mesh sieve, 5g of tapioca starch and 10g of tapioca pregelatinized starch in a dry powder state with 500g of wheat flour to form a raw material powder, dissolve 7.5g of table salt in 260g of drinking water and add to the raw material powder Carry out manual kneading operations, and after the kneading is completed, perform manual sheeting, strip cutting, hanging strips, room temperature drying, noodle cutting, finished product inspection and packaging operations in sequence. The total sensory evaluation score of the blank dried noodle sample without rice bran dietary fiber is 89 points, and the total sensory evaluation score of this batch of rice bran dietary fiber dried noodles is 85 points. The scoring results are as follows: figure 1 As shown in "7%DF+1%S+2%MS" (the sensory evaluation criteria of dried noodles are shown in Table 1), it can be seen that the dried noodle product has a medium-to-high sensory quality. Const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com