Preparation method for lithium iron phosphate/carbon composite positive material with high multiplying power

A technology of lithium iron phosphate and positive electrode materials, which is applied in the direction of phosphorus compounds, chemical instruments and methods, battery electrodes, etc., can solve the problems of low purity, low density, and unstable quality of iron salts, etc., so as to reduce production costs and reduce The effect of environmental stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

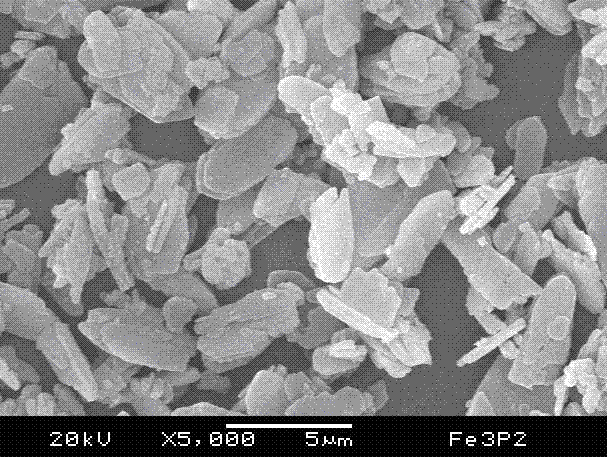

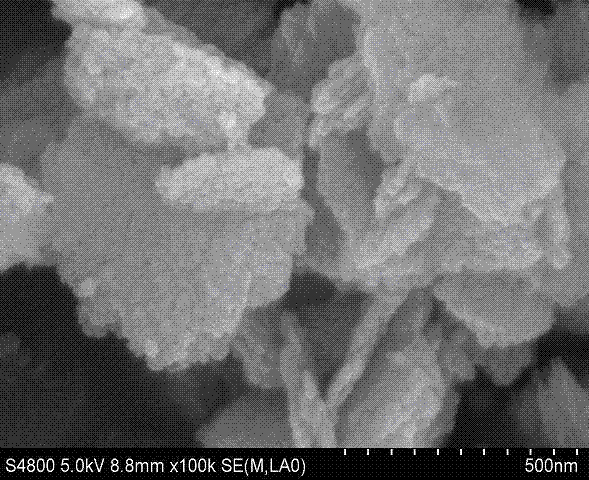

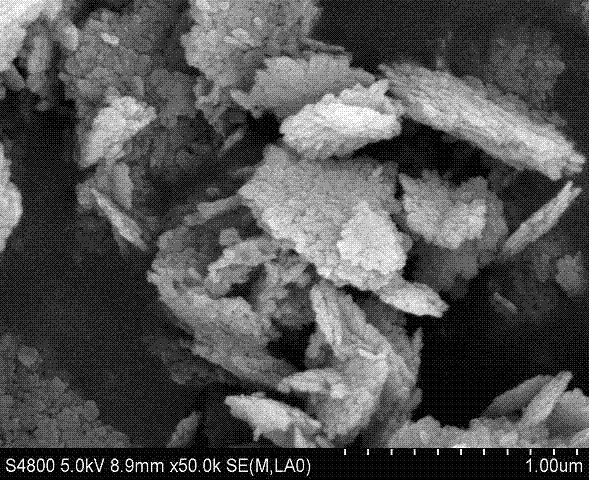

Image

Examples

Embodiment Construction

[0021] Implementation example 1 :

[0022] in N 2 Under protection, FeSO with a molar concentration of 1.3mol / L after purification 4 Solution 120mL was added to 80mL molar concentration of 1.3mol / L (NH 4 ) 2 HPO 4 in, while to NH 4 h 2 PO 4 Add 0.1g dispersant PVP into the solution, add 1:3 NH under stirring 3 ·H 2 O, adjust the pH value to 7.0, after 1 hour of reaction, Fe 3 (PO 4 ) 2 ·8H 2 O precipitation. After filtration and washing, the Fe 3 (PO 4 ) 2 ·8H 2 O was transferred to a beaker, 0.25mol phosphoric acid was added, and H was added after 1 hour of reaction 2 o 2 About 2.78g, with NH 3 .H 2 O (1:3) adjusts the pH of the system to 2.0, and after aging for 3 hours, the precipitate is filtered and dried to obtain FePO 4 2H 2 O powder.

[0023] Weigh FePO 4 2H 2 O powder 10.0g, analytically pure LiOH·H 2 O 2.35g, analytically pure glucose 1.0g, add 10ml of distilled water, ball mill for 2 hours, then dry at 100°C for 8 hours and place in N 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com