Amplification culture method for producing ethanol microorganisms by virtue of co-fermentation of C5 and C6

A technology for expanding the cultivation of microorganisms, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as difficulty in realizing large-scale industrial application, low vitality, and slow growth and proliferation of microorganisms, and achieve beneficial Effects of rapid proliferation, enhanced fermentation activity, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

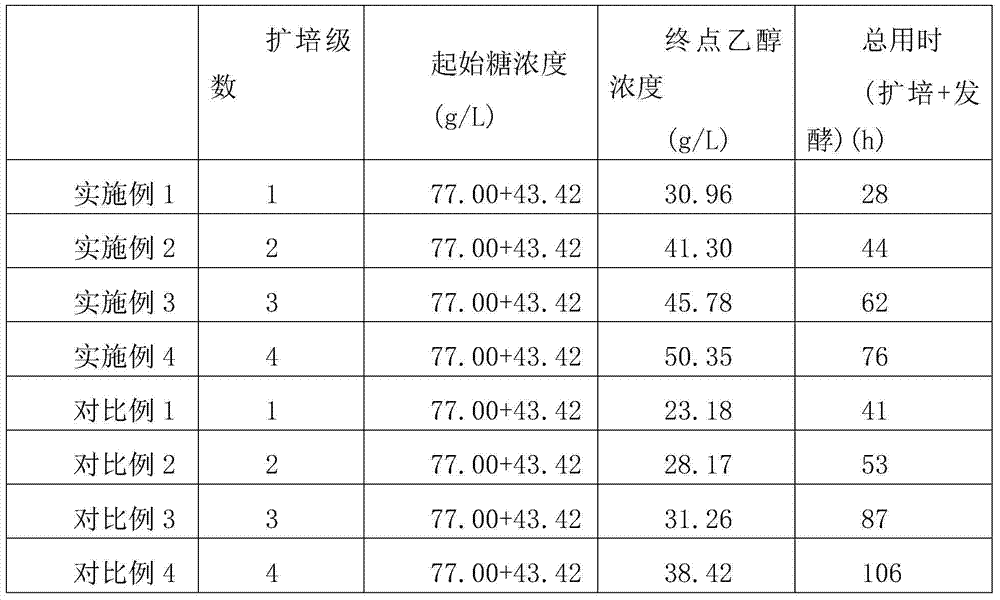

Examples

Embodiment 1

[0051] This example provides an expanded culture method for microorganisms that co-ferment C5 and C6 to produce ethanol. Taking recombinant S. -ST) (such as Cellulosic ethanol production from AFEX-treated corn stover using Saccharomyces cerevisiae 424A (LNH-ST), M.W. Lau, B.E. Dale, Proc Natl Acad Sci USA, 106 (2009), pp. 1368-1373; Two-step SSCF to convert AFEX-treated switchgrass to ethanol using commercial enzymes and Saccharomyces cerevisiae 424A(LNH-ST), M. Jin, M.W. Lau, V. Balan, B.E. Dale, Bioresour Technol, 101 (2010), pp. 8171–8178, etc. report), which is commercially available, and the expansion cultivation method adopts a first-level expansion cultivation step, which specifically includes:

[0052] A. Seed liquid culture steps

[0053] Prepare YEPD medium, inoculate the above-mentioned preserved bacteria into YEPD medium, control the temperature at 25°C, pH6.0, rotation speed 200rpm, ventilation volume 0.2vvm, and cultivate for 12h until the concentration of the a...

Embodiment 2

[0067] This example provides an expanded culture method for microorganisms that co-ferment C5 and C6 to produce ethanol. Taking Candida tropicalis as an example to carry out the expanded culture experiment, the Candida tropicalis is commercially available, and the expanded culture The method adopts two-stage expanded culture steps, which specifically include:

[0068] A. Seed liquid culture steps

[0069] Prepare YEPD medium, inoculate the above-mentioned preserved bacteria into YEPD medium, control the temperature at 25°C, pH6.0, rotating speed at 200rpm, and ventilation at 0.2vvm, and cultivate until the concentration of the above-mentioned bacteria is (0.1-0.5)×10 9 / ml;

[0070] The YEPD medium specifically contains 10 g / L of yeast powder, 20 g / L of peptone, and 20 g / L of glucose, and the pH is adjusted to 6.0.

[0071] B. Expand the cultivation steps

[0072] 1) Put the cultured seed solution into a 50L primary expansion tank containing a primary expansion medium at an...

Embodiment 3

[0085] This example provides an expanded culture method for microorganisms that co-ferment C5 and C6 to produce ethanol. Taking recombinant Saccharomyces cerevisiae 424A (LNH-ST) as an example to carry out the expanded culture experiment (same as Example 1), the expanded culture method Adopt three-level expansion culture steps, including:

[0086] A. Seed liquid culture steps

[0087] Prepare YEPD medium, inoculate the above-mentioned preserved bacteria into YEPD medium, control the temperature at 30°C, pH6.0, ventilation rate 0.2vvm, and rotation speed 200rpm, and cultivate for 14h until the concentration of the above-mentioned bacteria is (0.2-0.3)× 10 9 / ml;

[0088] The YEPD medium specifically contains 5 g / L of yeast powder, 1 g / L of peptone, and 25 g / L of glucose, and the pH is adjusted to 6.5.

[0089] B. Expand the cultivation steps

[0090] 1) Put the cultured seed liquid into a 50L primary expansion tank containing a primary expansion medium at an inoculation amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com