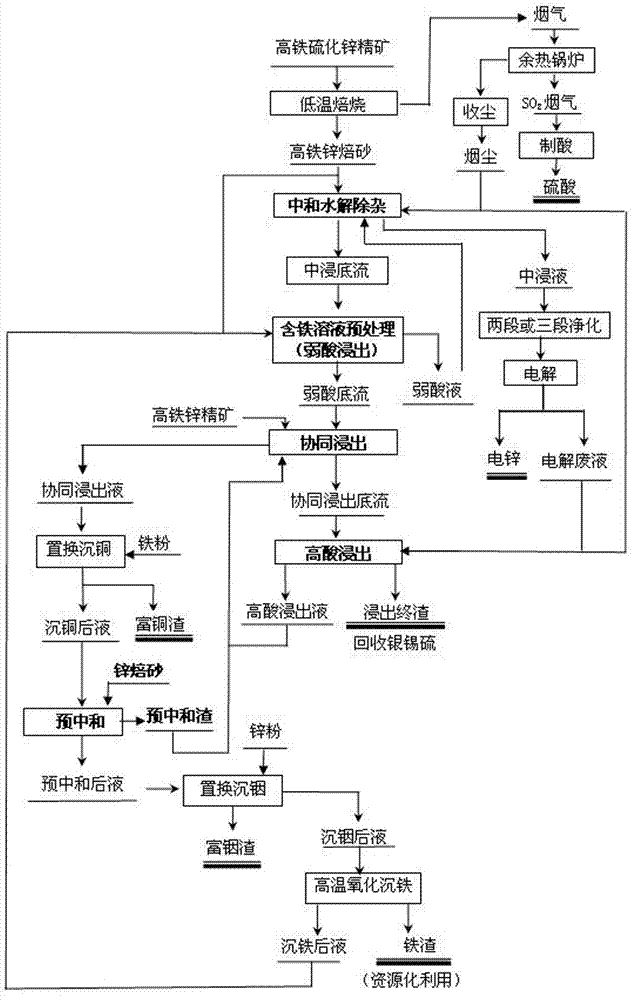

Treatment technique of copper-containing high-indium high-iron zinc sulfide concentrate

A technology of zinc sulfide concentrate and processing technology, which is applied in the direction of photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems that copper and tin are not effectively recovered, hematite slag is difficult to sell, and iron content is high. Achieve clean and efficient smelting process, avoid flue gas pollution, and achieve zero discharge of waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Mix 50kg of high-iron zinc calcine with 500L of weak acid solution containing 150g / L of zinc and 0.8g / L of iron and 135L of waste electrolyte containing 45g / L of zinc and 160g / L of sulfuric acid, and control the reaction temperature at 60°C. React for 2 hours, carry out neutralization and hydrolysis to remove impurities, and obtain the infusion solution containing zinc 152g / L, copper 0.6g / L, fluorine 0.042g / L, chlorine 0.143g / L, iron 15mg / L and zinc 22 %, middle leaching residue containing 29% iron.

[0033] 2. Add 45kg of high-iron zinc calcined sand and 23kg of leaching slag to 550L of iron-precipitated solution containing 106g / L zinc and 6.5g / L iron, keep the reaction temperature at 80°C, and react for 6 hours to carry out pretreatment of the iron-containing solution. A weak acid solution containing 150g / L of zinc, 0.6g / L of copper, 0.022g / L of fluorine, 0.110g / L of chlorine, and 0.8g / L of iron and a weak acid slag containing 18% of zinc and 32% of iron were obtai...

Embodiment 2

[0041] 1. Mix 55kg of high-iron zinc calcine with 500L of weak acid solution containing 151g / L of zinc and 0.3g / L of iron and 145L of waste electrolyte containing 45g / L of zinc and 160g / L of sulfuric acid, and control the reaction temperature at 70°C. React for 2 hours, carry out neutralization and hydrolysis to remove impurities, and obtain the infusion solution containing zinc 153g / L, copper 0.5g / L, fluorine 0.039g / L, chlorine 0.131g / L, iron 8mg / L and zinc 21 %, middle leaching residue containing 29% iron.

[0042] 2. Add 50kg of high-iron zinc calcined sand and 28kg of leaching slag to 550L of iron-precipitated solution containing 106g / L zinc and 4.2g / L iron, keep the reaction temperature at 90°C, and react for 4 hours to carry out pretreatment of the iron-containing solution. A weak acid solution containing 151g / L of zinc, 0.5g / L of copper, 0.028g / L of fluorine, 0.119g / L of chlorine, and 0.3g / L of iron and a weak acid slag containing 19% of zinc and 31% of iron were obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com