Method for fabricating surface-enhanced Raman scattering substrates with metal nanogap using ALD

A surface-enhanced Raman and metal nanotechnology, which is applied in Raman scattering, metal material coating technology, gaseous chemical plating, etc., can solve the problems of poor stability and repeatability, difficulty in preparing micro-nano structures in large areas, and high production costs and other problems, to achieve the effect of simple steps, good repeatability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

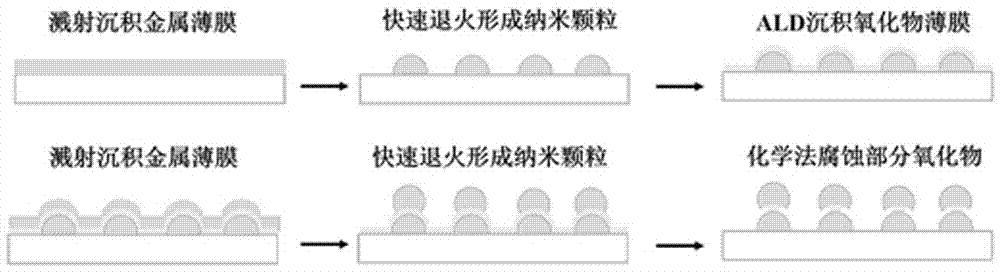

[0031] (1) figure 1 Is a flow chart of the method of the present invention, such as figure 1 As shown, the silicon wafer was ultrasonically cleaned with acetone, isopropanol, ethanol, and deionized water for 5 minutes, respectively.

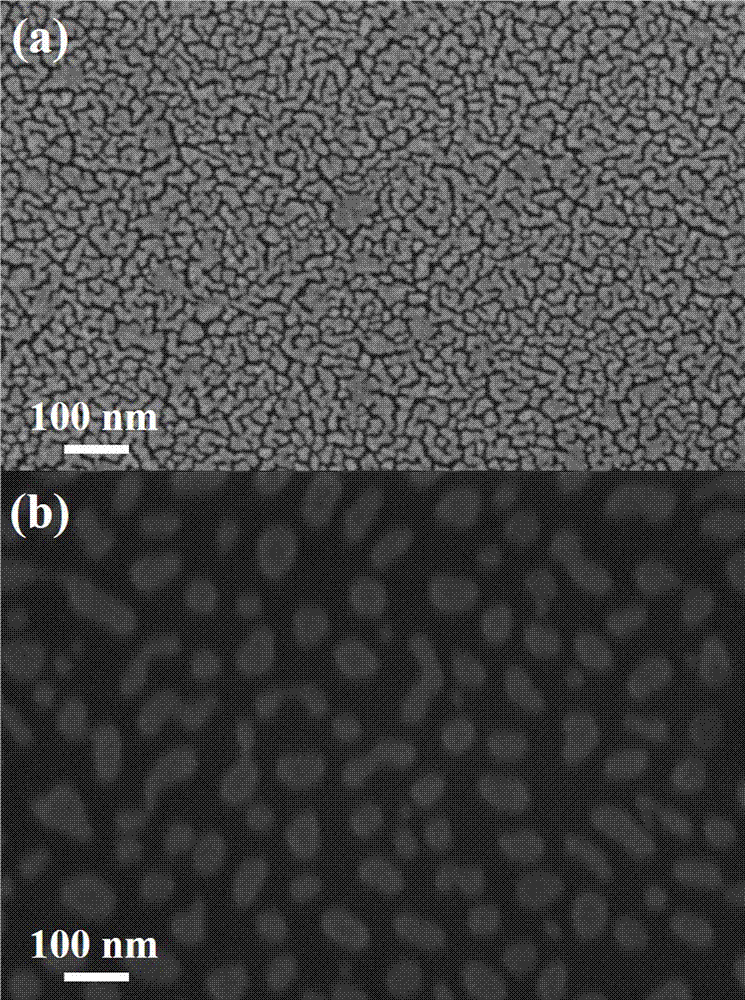

[0032] (2) Transfer the cleaned substrate to the magnetron sputtering reaction chamber, and deposit about 3nm Au thin film, figure 2 (A) is the SEM image of the Au thin film; under a nitrogen atmosphere, the Au thin film is subjected to rapid annealing at 500° C. for 30 seconds to generate Au nanoparticles; figure 2 (B) is the SEM image of Au nanoparticles.

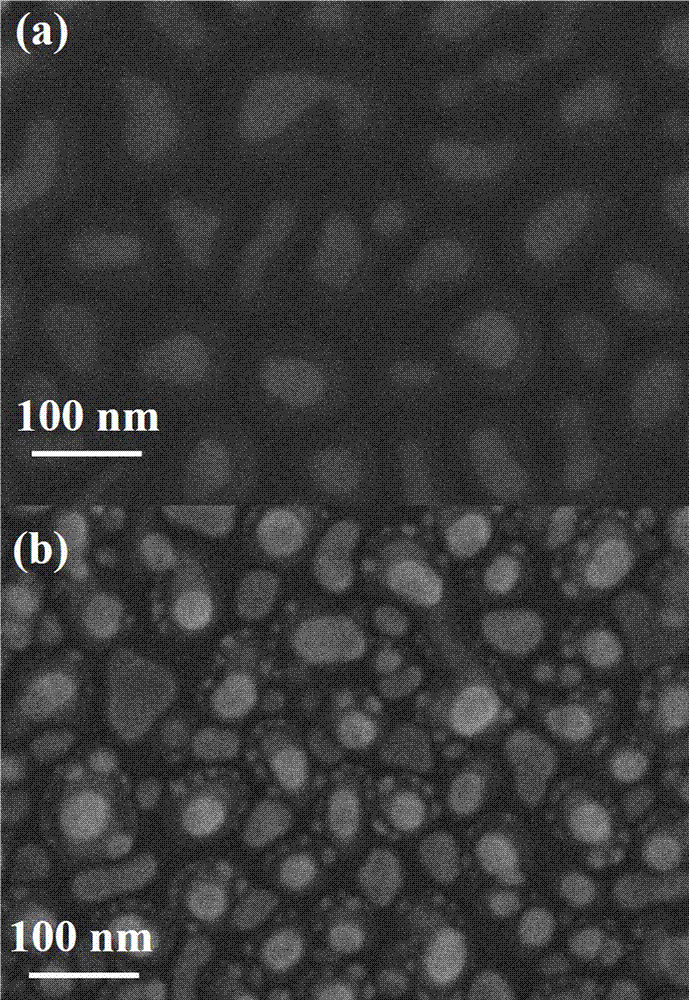

[0033] (3) Transfer the Au nanoparticle substrate obtained in step 2 to the ALD reaction chamber, and deposit 2nm, 10nm and 20nm Al respectively 2 O 3 Thin film, forming Al 2 O 3 Wrapped gold nanoparticle structure, image 3 (A) For wrapping 20nmAl 2 O 3 SEM image of the gold nanoparticle structure of the film.

[0034] ALD deposited Al 2 O 3 The parameters are:

[0035] Reaction chamber temperat...

Embodiment 2

[0042] (1) Wash the quartz glass with acetone, isopropanol, ethanol and deionized water, respectively, ultrasonically for 5 minutes;

[0043] (2) Transfer the cleaned substrate to the electron beam evaporation reaction chamber, and deposit a silver film of about 5nm; in a nitrogen atmosphere, the silver film is subjected to rapid annealing at 500 ℃ for 50 seconds to generate silver nanoparticles;

[0044] (3) Transfer the substrate with silver nanoparticles to the ALD reaction chamber, and grow a 5nm zinc oxide film to form zinc oxide-coated silver nanoparticles;

[0045] The parameters of ALD deposition of zinc oxide are:

[0046] Reaction chamber temperature 150 o C, with Zn(C 2 H 5 ) 2 And H 2 O is the reaction source, first pass in Al(CH 3 ) 3 Pulse 0.1s, followed by high-purity nitrogen pulse cleaning for 4s to wash away the reaction by-products and residual reaction sources, and finally water vapor pulse for 0.1s; the above is a cycle of atomic layer deposition, according to the ...

Embodiment 3

[0051] (1) Wash the silicon wafers with acetone, isopropanol, ethanol, and deionized water, respectively, ultrasonically for 5 minutes;

[0052] (2) Transfer the cleaned substrate to the ALD reaction chamber, and deposit 100 cycles of Pt nanoparticles with a thickness of about 5nm. The resulting Pt nanoparticles are as Figure 8 Shown.

[0053] The parameters of ALD deposition of Pt are:

[0054] Reaction chamber temperature 300 o C, to PtMeCpMe 3 And O 2 As the reaction source, PtMeCpMe 3 The source temperature is 70 o C; access to PtMeCpMe first 3 Pulse 0.2s, followed by nitrogen pulse cleaning for 4s, then pass O 2 The pulse is 1.5s, and finally high-purity nitrogen is pulsed and flushed for 20s; the above is a cycle of atomic layer deposition. According to the desired thickness of the Pt film, the cycle is repeated. In this embodiment, a total of 100 cycles are performed.

[0055] (3) Then deposit 5 nm SiO in the ALD reaction chamber 2 Thin film, forming Pt nanoparticle structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com