Waterborne nail polish based on aqueous polyurethane dispersion

A water-based polyurethane and nail polish technology, applied in manicure, cosmetics, cosmetic preparations, etc., can solve the problems of poor gloss, non-toxicity, poor adhesion, etc., achieve excellent fullness and gloss, excellent dry time, excellent The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

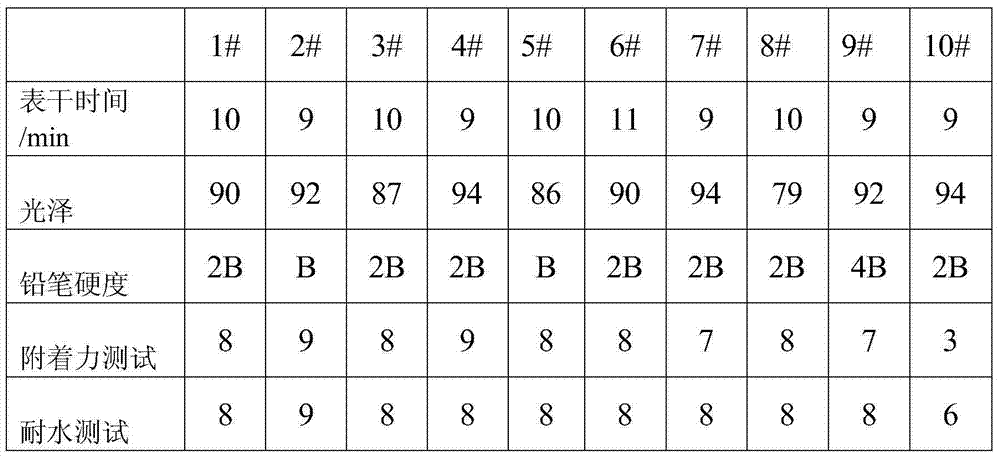

Examples

Embodiment 1

[0051] Water-based nail polish consists of the following ingredients:

[0052] (a) 98.0g of Carfil 9230; Waterborne Polyurethane Dispersion

[0053] (b) 0.8g of YCK1110; leveling agent

[0054] (c) 0.5 g of LCN407; wetting agent

[0055] (d) 0.5 g of 2-1352 emulsion; brightening agent

[0056] (e1) 0.01g of nano-alumina dispersion (wt%=10%); hardening agent

[0057] (e2) 0.01 g of aldehyde and ketone resins; hardeners

[0058] (f1) 1.0 g of Lakewax 20; thickener

[0059] (f2) 1.0 g of bentonite; thickener

[0060] (f3) 1.0 g of Carfil 9241; Thickener

[0061] (g) 0.4 g of KH-560; adhesion promoter

[0062] (h1) 5.0g of SM-9815; color paste

[0063] (h2) 3.0g of AG300; pearlescent

[0064] (i1) 1.0 g of TCW2890404; fragrance

[0065] (i2) 1.0 g of DMDMH. preservative

[0066] After the above components are weighed, IKA stirrer 1000r / min high-speed stirring for 2 hours to mix evenly to make 1# nail polish.

Embodiment 2

[0068] Water-based nail polish consists of the following ingredients:

[0069] (a) 90.0g of Carfil 9230; Dispersion

[0070] (b) 0.5g of YCK1110; leveling agent

[0071] (c) 0.05 g of LCN407; wetting agent

[0072] (d) 0.8 g of 2-1352 emulsion; brightener

[0073] (e1) 0.2g of nano-alumina dispersion (wt%=30%); hardening agent

[0074] (e2) 0.8 g of aldehyde and ketone resin; hardening agent

[0075] (f1) 0.5g of Lakewax20; thickener

[0076] (f2) 0.5 g of bentonite; thickener

[0077] (f3) 1.0 g of Carfil 9241; Thickener

[0078] (f4) 1.0g of Carfil 9240;Thickener

[0079] (g) 0.9 g of KH-560; adhesion promoter

[0080] (h1) 4.0g of SM-9815; color paste

[0081] (h2) 1.5g of AG300; pearlescent

[0082] (i1) 1.5g of TCW2890404; fragrance

[0083] (i2) 1 g of DMDMH. preservative

[0084] After the above ingredients are weighed, IKA stirrer 1000r / min high-speed stirring for 2 hours to mix evenly to make 2# nail polish.

Embodiment 3

[0086] Water-based nail polish consists of the following ingredients:

[0087] (a) 82.0g of Carfil 9230; Dispersion

[0088] (b) 0.05g of YCK1110; leveling agent

[0089] (c) 0.05 g of LCN407; wetting agent

[0090] (d) 0.05 g of 2-1352 emulsion; brightening agent

[0091] (e1) 0.2g of nano-alumina dispersion (wt%=20%); hardening agent

[0092] (e2) 0.25 g of aldehyde and ketone resin; hardening agent

[0093] (f1) 0.5g of Lakewax20; thickener

[0094] (f2) 0.5 g of bentonite; thickener

[0095] (f3) 0.5g Carfil 9241; Thickener

[0096] (f4) 0.5g Carfil 9240;Thickener

[0097] (g) 0.5 g of KH-560; adhesion promoter

[0098] (h) 8.0g of SM-9815; color paste

[0099] (i) 2.5g of TCW2890404; flavor

[0100] After the above ingredients are weighed, IKA stirrer 1000r / min high-speed stirring for 2 hours to mix evenly to make 3# nail polish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com