Deep purification technology of high concentration sodium aluminate solution

A purification process and deep purification technology, applied in the field of aluminum metallurgy, can solve the problems of deep purification and difficulty in removing impurities from sodium aluminate solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

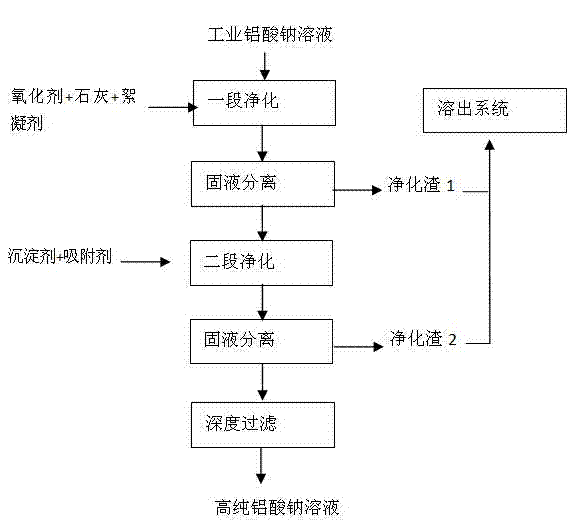

[0023] The deep purification process of the high-concentration sodium aluminate solution of the present embodiment is as follows:

[0024] (1) One-stage solution purification: take industrial high-concentration sodium aluminate solution, alkali concentration (taken as Na 2 O meter), the alumina concentration is 150g / L, 165g / L respectively. After adding 5mL / L hydrogen peroxide with a concentration of 20% at 90°C and reacting, the positive electrode is connected with direct current and the voltage is 5V, and the electrophoresis principle is used to enrich the iron-containing hydroxide colloid for 30min, then add 10g / L quicklime, stir vigorously for 1h, and then add 2ml / L of 1‰ hydroxamic acid-containing flocculant HX300, flocculation and sedimentation for 1 hour, suction filtration to obtain a section of purified clear liquid;

[0025] (2) Second-stage solution purification: add 0.5g / L Na to the first-stage purification solution at 70°C 2 S, 1g / L Na 3 PO 4 , 2g / L NaF, add ac...

Embodiment 2

[0028] The deep purification process of the high-concentration sodium aluminate solution of the present embodiment is as follows:

[0029] (1) One-stage solution purification: take industrial high-concentration sodium aluminate solution, alkali concentration (taken as Na 2 O meter), the alumina concentration is 172g / L, 185g / L respectively. At 90°C, add 20% hydrogen peroxide 2mL / L and 2g / L sodium peroxide as the oxidizing agent, connect the positive electrode with direct current, voltage 2V, time 30min, use electrophoresis principle to enrich the iron-containing hydroxide colloid, and then heat the solution to 100°C, add 10g / L quicklime and stir vigorously for 1h, then add 5ml / L 1‰ polyacrylamide flocculant KM800 (French Essen Company), flocculate and settle for 1h, then suction filter to obtain a purified clear liquid;

[0030] (2) Second-stage solution purification: add 1g / L Na to the first-stage purification solution at 50°C 2 S, 3g / L Na 3 PO 4 , 6g / L NaF, 4g / L sodium ca...

Embodiment 3

[0033] The deep purification process of the high-concentration sodium aluminate solution of the present embodiment is as follows:

[0034] (1) One-stage solution purification: take industrial high-concentration sodium aluminate solution, alkali concentration (taken as Na 2 O meter), the alumina concentration is 131g / L, 142g / L respectively. Add 10g / L sodium peroxide and 10g / L sodium persulfate at 90°C, connect the positive electrode with direct current, voltage 20V, time 10min, use the principle of electrophoresis to enrich the iron-containing hydroxide colloid, then raise the temperature of the solution to 95°C and add 10g / L quicklime, stir vigorously for 1 hour; then add 5ml / L 1‰ polyacrylamide-containing flocculant KM800 (French Eisen Company) and hydroxamic acid-containing flocculant HX300 (American Cytec Company), flocculate and settle for 1 hour and pump Filter to obtain a section of purified clear liquid;

[0035] (2) Second-stage solution purification: add 0.1g / L Na ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com