Organic thin-film solar cell based on three emitting layers and preparing method thereof

A technology of solar cells and organic thin films, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problem of generating photocurrent, unable to solve the problem of excitons quenching and entering the anode or anode modification layer, and unable to form excitons. Sub-transmission and other issues, to achieve the effect of improving photocurrent, improving light absorption efficiency, and increasing utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

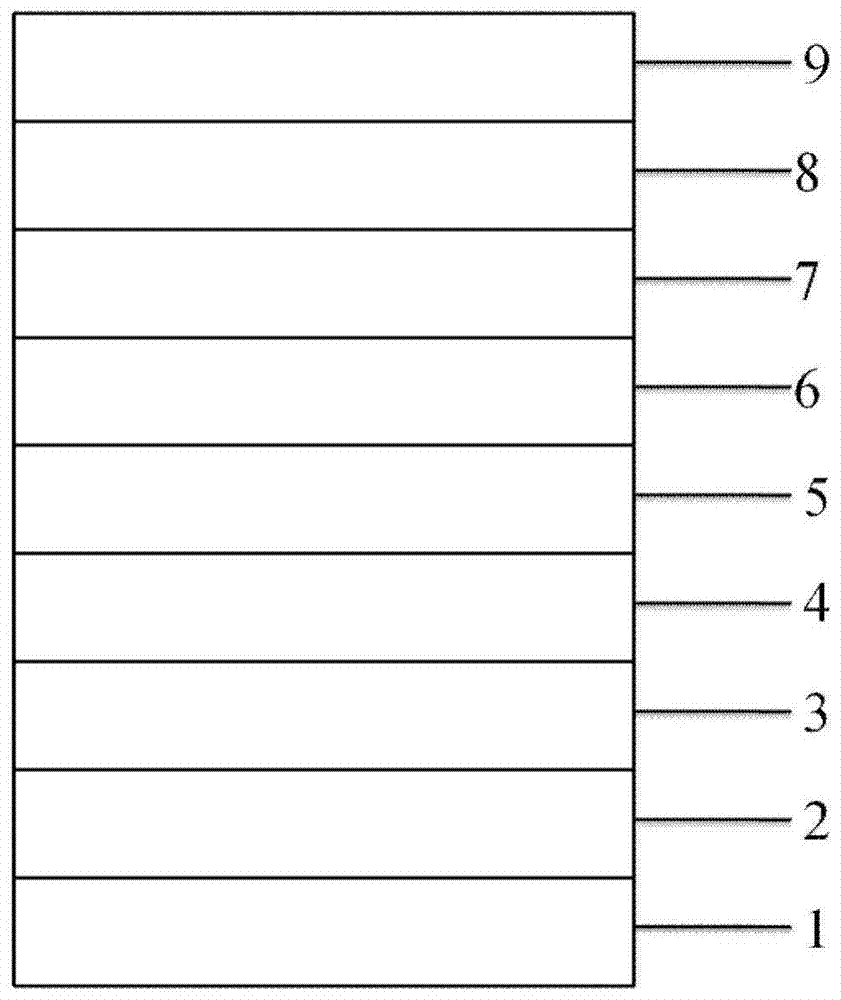

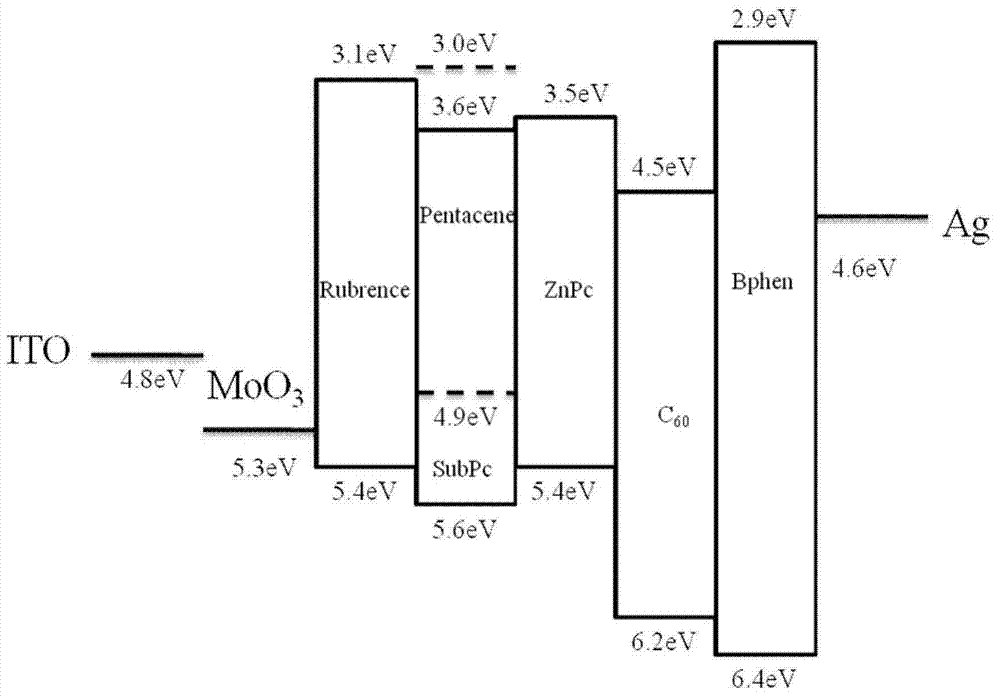

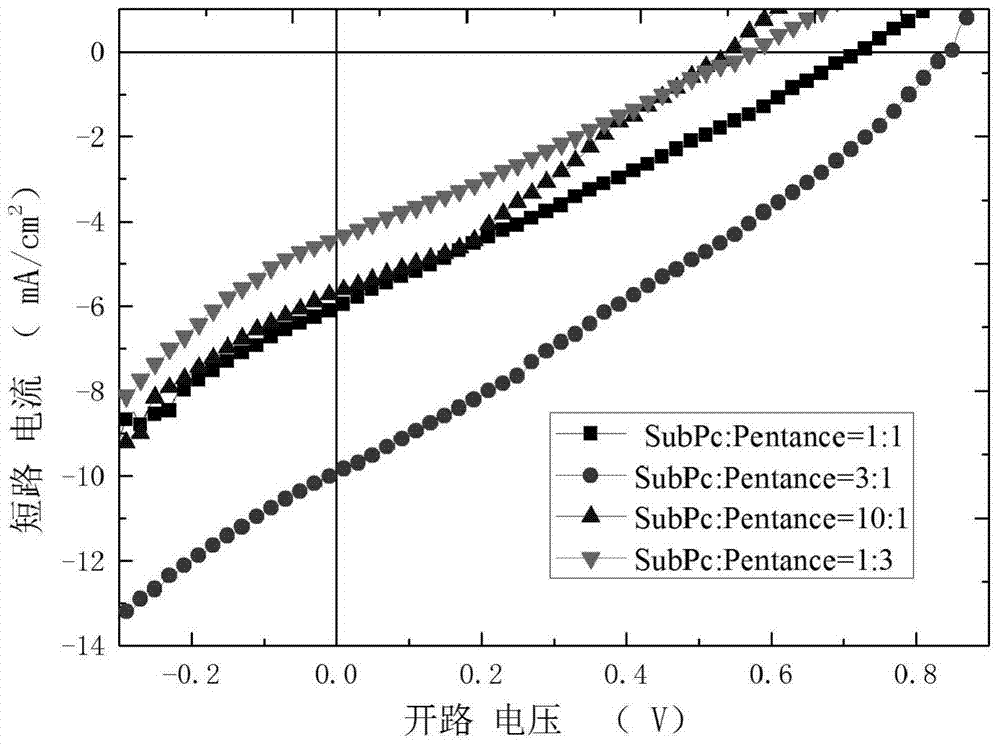

Embodiment 1

[0048] The structure of organic solar cells such as figure 2 shown. The material, thickness and doping ratio of each layer of the device are as follows: the transparent substrate is glass, the transparent anode electrode is ITO, and the thickness is 180nm; the anode modification layer is MoO 3 , the thickness is 10nm; the first donor layer is Rubrene, the thickness is 5nm; the second donor layer is SubPc: Pentance=10:1, the thickness is 7nm; the third donor layer is ZnPc, the thickness is 5nm; the acceptor layer for C 60 , the thickness is 30nm; the electronic buffer layer is Bphen, the thickness is 5nm; the cathode electrode is Ag, the thickness is 130nm.

[0049] Its preparation method is as follows:

[0050] ① The glass substrate on which the transparent anode electrode ITO has been sputtered is ultrasonically cleaned with detergent, deionized water, acetone solution and ethanol solution, and dried with dry nitrogen after cleaning;

[0051] ② Move the above-mentioned I...

Embodiment 2

[0060] The structure of organic solar cells such as figure 2 shown. The material, thickness and doping ratio of each layer of the device are as follows: the transparent substrate is glass, the transparent anode electrode is ITO, and the thickness is 180nm; the anode modification layer is MoO 3 , the thickness is 10nm; the first donor layer is Rubrene, the thickness is 5nm; the second donor layer is SubPc: Pentance=3:1, the thickness is 7nm; the third donor layer is ZnPc, the thickness is 5nm; the acceptor material Layer is C 60 , the thickness is 30nm; the electronic buffer layer is Bphen, the thickness is 5nm; the cathode electrode is Ag, the thickness is 130nm. The preparation process is basically similar to Example 1.

Embodiment 3

[0062] The structure of organic solar cells such as figure 2 shown. The material, thickness and doping ratio of each layer of the device are as follows: the transparent substrate is glass, the transparent anode electrode is ITO, and the thickness is 180nm; the anode modification layer is MoO 3 , the thickness is 10nm; the first donor layer is Rubrene, the thickness is 5nm; the second donor layer is SubPc: Pentance=1:3, the thickness is 7nm; the third donor layer is ZnPc, the thickness is 5nm; the acceptor material Layer is C 60 , the thickness is 30nm; the electronic buffer layer is Bphen, the thickness is 5nm; the cathode electrode is Ag, the thickness is 130nm. The preparation process is basically similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com