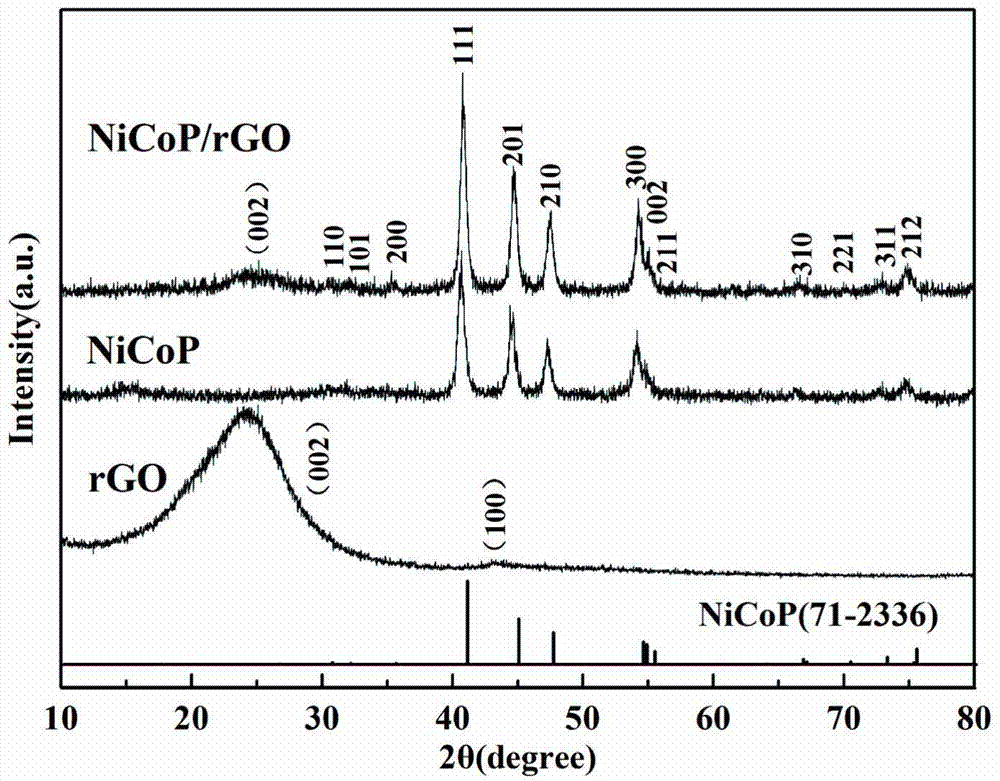

Preparation method for graphene loaded cobalt nickel phosphide composite material

A nickel-cobalt phosphide and composite material technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as unfavorable environmental protection, safe experimental operation, performance degradation, etc., and achieve good applications. Prospects, improved electrical properties, the effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

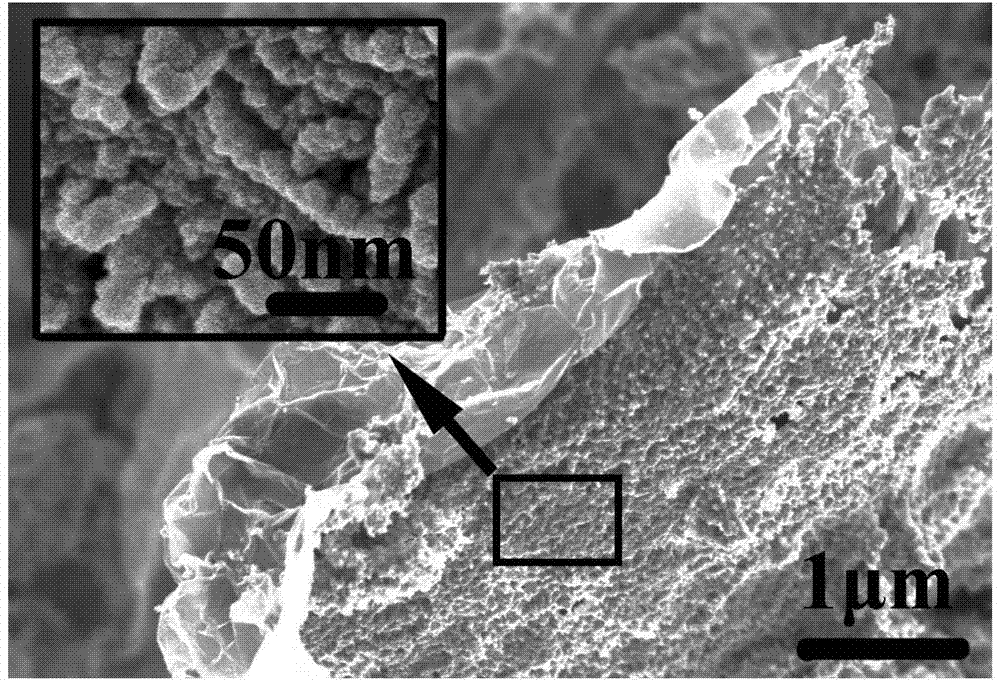

Embodiment 1

[0024] A kind of preparation method of graphene supported nickel-cobalt phosphide composite material, comprises the following steps:

[0025] 1) Add 20 mL of deionized water into the beaker, add 0.325 g of nickel acetate tetrahydrate and 0.286 g of cobalt sulfate heptahydrate, and stir until completely dissolved to form a clear and transparent solution;

[0026] 2) The graphene oxide prepared by the Hummers method and obtained by freeze-drying was dissolved in an Erlenmeyer flask containing 15 mL of deionized water, and ultrasonicated until a uniform graphene oxide solution was formed, and the graphene oxide concentration was 0.35 g / L;

[0027] 3) Add the solution obtained in step 2) into the beaker of step 1) and continue to stir, then transfer the uniform liquid to the polytetrafluoroethylene lining;

[0028] 4) Add 0.260g of red phosphorus to the liquid in step 3), stir until suspended solids appear on the surface of the solution, seal the polytetrafluoroethylene lining int...

Embodiment 2

[0033] Change the 0.325g nickel acetate tetrahydrate into 0.438g nickel chloride hexahydrate in step 1) in Example 1, and keep other conditions unchanged. The average particle size of nickel-cobalt phosphide in the obtained graphene-supported nickel-cobalt phosphide composite material is reduced, and the coating conditions are basically the same.

Embodiment 3

[0035] The 0.286g cobalt sulfate heptahydrate of step 1) in embodiment 1 is changed into 0.347g cobalt chloride hexahydrate, and other conditions are constant, and the particle particle in the gained graphene-loaded nickel-cobalt phosphide composite material becomes bigger, and coating amount simultaneously Less, more exposed smooth graphene can be observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com