Preparation method of WO3/C3N4 mixed photocatalyst

A C3N4, catalyst technology, applied in the field of nanotechnology, can solve the problems of low catalytic efficiency of composite materials, and achieve the effects of short catalytic time, improved photocatalytic activity, and improved catalytic degradation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a WO 3 / C 3 N 4 The preparation method of composite photocatalyst specifically comprises the following steps:

[0028] (1) Preparation of WO by hydrothermal method 3 Nano powder

[0029] Calculated by mass ratio, Na 2 WO 4 : NaCl: deionized water in a ratio of 1:1.4:38, put 1.65g of Na 2 WO 4 , 2.32g of NaCl was added to 38.0g of deionized water, stirred to make it all dissolved, to obtain a mixed solution, then adjusted pH to 2.0 with an aqueous HCl solution with a mass percentage concentration of 36-37%, and then the resulting pH was 2.0 The magnetic stirring speed of the mixed solution is controlled to be 300-500r / min, and after stirring for 1 hour, it is placed in a hydrothermal reaction kettle. The precipitation was washed with deionized water under the condition of superspeed until the pH of the eluate was neutral, and then the temperature was controlled at 80 °C and dried for 10 h, and then cooled to room temperature naturally to obtain WO 3 Na...

Embodiment 2

[0038] a WO 3 / C 3 N 4 The preparation method of composite photocatalyst specifically comprises the following steps:

[0039] (1), only the mixed solution is adjusted to pH 3.0 with an aqueous HCl solution with a mass percentage concentration of 36-37%, and the other steps (1) are the same as in Example 1;

[0040] (2), with the step (2) of embodiment 1, obtain C 3 N 4 ;

[0041] (3), with the step (3) of embodiment 1, obtain WO 3 / C 3 N 4 Composite Photocatalyst B.

Embodiment 3

[0043] a WO 3 / C 3 N 4 The preparation method of composite photocatalyst specifically comprises the following steps:

[0044] (1), only the mixed solution is adjusted to pH 3.5 with an aqueous HCl solution with a mass percentage concentration of 36-37%, and other steps (1) are the same as in Example 1;

[0045] (2), with the step (2) of embodiment 1, obtain C 3 N 4 ;

[0046] (3), with the step (3) of embodiment 1, obtain WO 3 / C 3 N 4 Composite photocatalyst C.

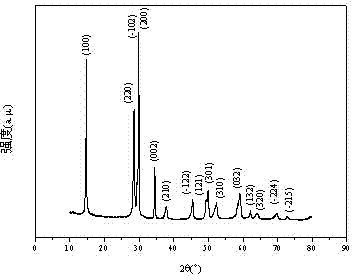

[0047] The WO obtained in the above step (1) was analyzed by X-ray diffractometer (PANalytical, PW3040 / 60, Netherlands). 3 Nano-powder was measured, the obtained WO 3 The X-ray diffraction pattern of the nanopowder is as follows: figure 2 shown, and with the standard WO 3 A comparison of the X-ray diffraction pattern of the card (00-043-1035, PDF card) shows that the resulting WO 3 Nano powder is pure phase.

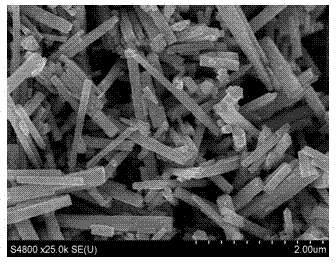

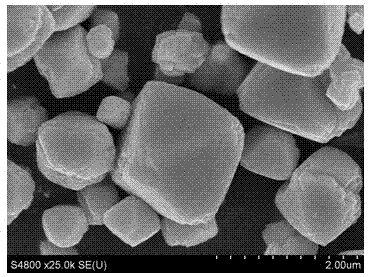

[0048] The WO obtained in the above step (1) was analyzed by Hitachi S-4800 field emission sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com