Technology of using ocean phaffiarodozyma for producing feed additive astaxanthin in fermentation mode

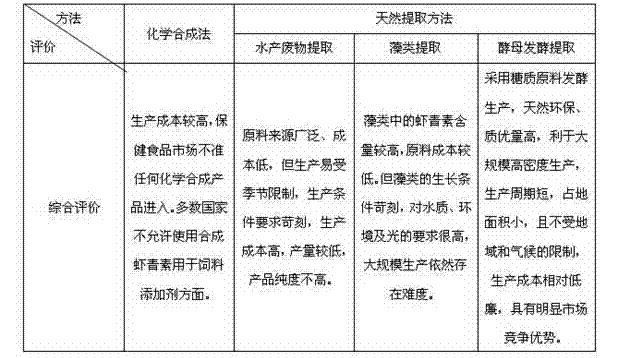

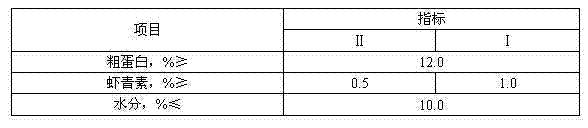

A feed additive, yeast technology, applied in fermentation, microorganism-based methods, microorganisms, etc., can solve the problems of no production scale, low production efficiency, low technical level, etc., to reduce production costs, improve production efficiency, and improve production efficiency. effect of prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

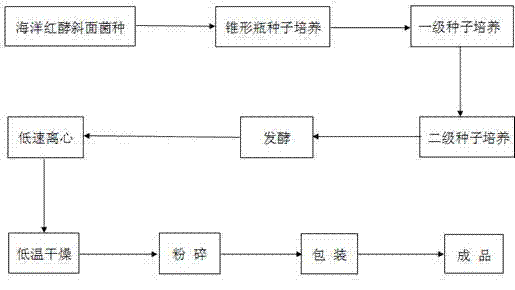

[0040] A process for producing feed additive astaxanthin by fermenting marine rhodotorula, comprising the following steps:

[0041] (1) Seed culture of Rhodotorula marinae: prepare liquid culture medium and divide it into 1000ml Erlenmeyer flasks, adjust pH=5.0, sterilize at high pressure 137kpa, high temperature 121℃ for 20min, and fill liquid volume to 400ml. After cooling, the strains were inoculated on an aseptic operating table, and then cultured in a shaking table at 30°C for 40 hours before being used for later use. The rotating speed of the shaking table was 160r / min.

[0042] Medium formula: glucose: 10g; yeast extract powder: 3g; peptone: 5g; wort juice: 3g; water: 100ml.

[0043] (2) First-level seed culture of Rhodotorula marinae: Inoculate the seeds of Rhodotorula marinae cultured for 40 hours into a 100L sterilized seed fermenter, with a liquid volume of 60%, an inoculum volume of 10%, a culture temperature of 30°C, and ventilation Cultivate with stirring for 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com