Cationic nano emulsion with anti-allergic effect and preparation method of cationic nano emulsion

A nanoemulsion and cationic technology, applied in the field of cationic nanoemulsion and its preparation, to achieve the effect of reducing allergic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] a. Weigh 30g of olive leaf extract, 10g of gorgonian coral extract, 20g of sugar kelp extract, 6g of kava pepper extract and 134g of octyldodecanol according to the mass ratio of 15:5:10:3:67. Heat octyldodecanol to 60°C, then add olive leaf extract, gorgonian coral extract, sugar kelp extract, and kava pepper extract respectively, and stir continuously with an IKA mixer at 1500 rpm until there is no sediment at the bottom, and pass through a 300-mesh The stainless steel filter removes mechanical impurities to obtain a uniform solution, cools to room temperature, and obtains the plant anti-allergic compound;

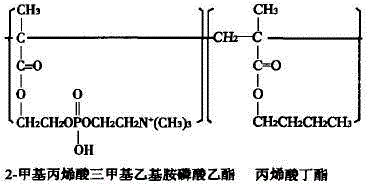

[0054] b. Weigh 6g of glycerin, 10g of caprylic acid / capric triglyceride, 0.2g of cholesterol, 4g of glycolipid, and 0.2g of polyquaternium-51 according to the mass ratio of 3:5:0.1:2:0.1:10:0.05:79.75 , Phase A 20g, methyl paraben 0.1g and water 159.5g; first mix glycerin, caprylic acid / capric triglyceride, cholesterol, glycolipid (purity ≥ 95%), methyl paraben i...

Embodiment 2

[0059] a. Take by weight 20:8:15:4:53 olive leaf extract 40g, gorgonian coral extract 16g, sugar kelp extract 30g, kava pepper extract 8g and octyldodecanol 106g, first Heat octyldodecanol to 65°C, then add olive leaf extract, gorgonian coral extract, sugar kelp extract, and kava pepper extract respectively, and continue stirring with an IKA mixer at 1500 rpm until there is no sediment at the bottom, and pass through a 300-mesh The stainless steel filter removes mechanical impurities to obtain a uniform solution, cools to room temperature, and obtains the plant anti-allergic compound;

[0060]b. Weigh glycerin 10g, caprylic acid / capric triglyceride 20g, cholesterol 2g, glycolipid 10g, polyquaternium-51 1g, A according to mass ratio 5:10:1:5:0.5:15:0.1:63.4 Phase 30g, methyl paraben 0.2g and water 126.8g; firstly, glycerin, caprylic acid / capric triglyceride, cholesterol, glycolipid (purity ≥ 95%), methyl paraben are mixed and heated in a stainless steel container to 95°C, stir...

Embodiment 3

[0065] a. Weigh 50g of olive leaf extract, 20g of gorgonian extract, 40g of sugar kelp extract, 10g of kava pepper extract and 80g of octyldodecanol according to the mass ratio of 25:10:20:5:40. Heat octyldodecanol to 65°C, then add olive leaf extract, gorgonian coral extract, sugar kelp extract, and kava pepper extract respectively, and continue stirring with an IKA mixer at 1500 rpm until there is no sediment at the bottom, and pass through a 300-mesh The stainless steel filter removes mechanical impurities to obtain a uniform solution, cools to room temperature, and obtains the plant anti-allergic compound;

[0066] b. Weigh 20g of glycerin, 30g of caprylic acid / capric triglyceride, 4g of cholesterol, 20g of glycolipid, polyquaternium-51 2g, A Phase 40g, methyl paraben 0.4g and water 119.6g; firstly, glycerin, caprylic acid / capric triglyceride, cholesterol, glycolipid (purity ≥ 95%), methyl paraben are mixed and heated in a stainless steel container to 95°C, stir with IKA ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com