Erbium silicate with sensitization effect as well as preparation method and application of erbium silicate

An erbium silicate and porous silicon technology, which is applied to the erbium silicate with sensitization effect and the field of preparation thereof, can solve the problems of no sensitized luminescence and weak luminescence, and achieve the effects of simple production process and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

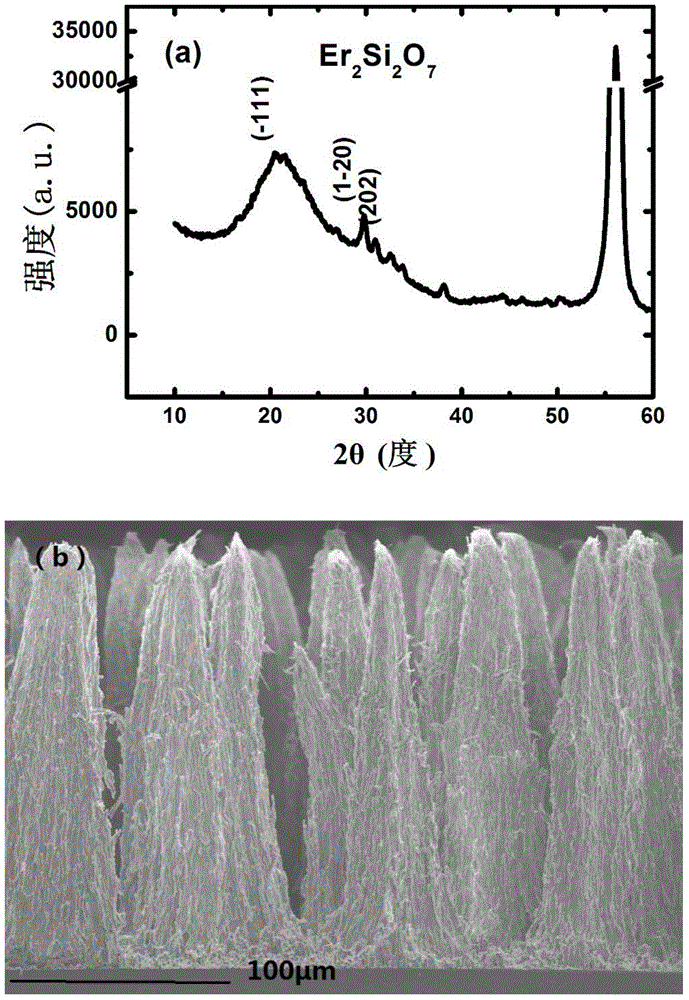

Embodiment 1

[0032] In this embodiment, a p-type Czochralski monocrystalline silicon wafer with (100) crystal orientation is adopted, the silicon wafer is polished on one side, and the resistivity ρ=0.001~0.01Ω.cm, and the erbium soluble compound used is erbium chloride hexahydrate It is obtained by dissolving the substance in alcohol. The heat treatment conditions are that the first stage is heated to 900°C and kept for 4 minutes, and the atmosphere is O 2 ; The second section continues to heat up to 1200 ° C and keep it warm for 3 minutes, the atmosphere is Ar.

[0033] The specific preparation method is as follows:

[0034] (1) Standard RCA cleaning is performed on the silicon wafer, and after rinsing in hydrofluoric acid, aluminum paste is screen-printed on the back of the silicon wafer. The silicon wafer brushed with aluminum paste was placed in a rapid heat treatment furnace for sintering, the sintering temperature was 700°C, the time was 50s, and the atmosphere was argon. After si...

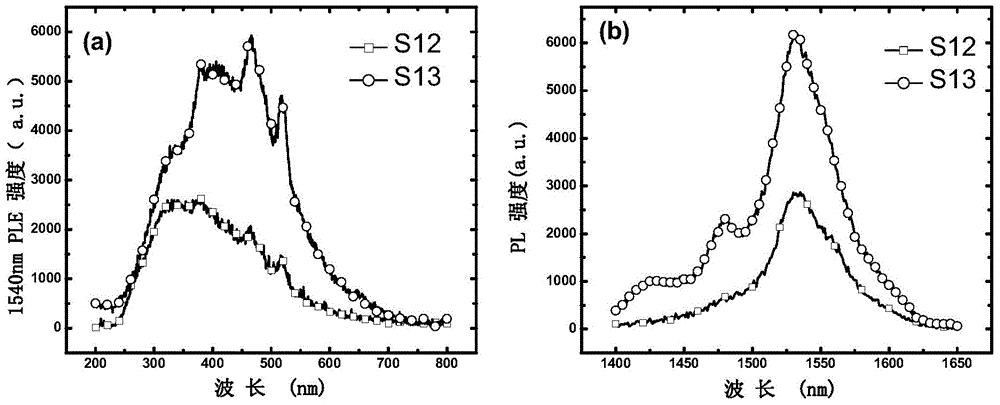

Embodiment 2

[0041] In this embodiment, the erbium silicate with sensitization effect prepared on the porous silicon is still a p-type Czochralski silicon wafer with a (100) crystal orientation, and the silicon wafer is polished on one side, and the resistivity ρ=0.001~0.01Ω.cm The erbium soluble compound used is obtained by dissolving erbium chloride hexahydrate in alcohol. The heat treatment conditions are that the first section is first heated to 900 ° C and kept for 4 minutes, and the atmosphere is O 2 ; The second section continues to heat up to 1200 ° C and keep it warm for 3 minutes, the atmosphere is Ar.

[0042] Concrete preparation method is as follows (similar to embodiment 1):

[0043] (1) Standard RCA cleaning is performed on the silicon wafer, and after rinsing in hydrofluoric acid, aluminum paste is screen-printed on the back of the silicon wafer. Put the silicon wafer brushed with aluminum paste in a rapid heat treatment furnace for sintering, the sintering temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com