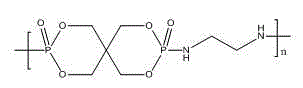

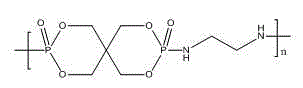

Phosphorous-containing epoxy resin amine curing agent and preparation method thereof

The technology of an amine curing agent and epoxy resin, which is applied in the field of chemical synthesis and its preparation, can solve the problems of application limitation, easy fire, low oxygen index of epoxy resin, etc., and achieve simple preparation method, easy control, mechanical good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step: to the equipped with reflux condenser, thermometer N 2 Add 13.62g of pentaerythritol and 23.8ml of phosphorus oxychloride into the 250ml three-necked bottle of the introduction tube and magnet, then add 80ml of chlorobenzene as solvent, 0.3g of AlCl 3 as a catalyst. Pass N 2 Protection, the temperature was raised to 60°C to start the reaction, after 1 hour, the temperature was raised to 80°C for 3 hours, and then the temperature was raised to 100°C for 8 hours. Pass N after the reaction 2 Protected and cooled to room temperature, a white liquid was obtained. After the liquid was filtered, washed and dried, a white powdery solid was obtained.

[0031] Step 2: In a 100ml three-neck flask equipped with magnetic stirring, dropping funnel and thermometer, add SPDPC5.94g and 40ml of acetonitrile, add 2.1ml of ethylenediamine to the dropping funnel and dilute with 10ml of acetonitrile until the temperature rises to 50 After 1.5 hours of dropping, keep t...

Embodiment 2

[0033] The first step: the synthetic method of phosphorus-containing intermediate is the same as embodiment 1.

[0034] Step two:

[0035] Step 2: In a 100ml three-neck flask equipped with magnetic stirring, dropping funnel and thermometer, add SPDPC5.94g and 40ml of acetonitrile, add 2.7ml of ethylenediamine to the dropping funnel and dilute with 10ml of acetonitrile until the temperature rises to 50 After 1.5 hours of dropping, keep the temperature at 70°C until no HCl gas is released, then slowly cool down to room temperature, filter, wash with dichloromethane for several times, and dry at 50°C to obtain a slightly Pale yellow powdery solid.

Embodiment 3

[0037] The first step: the synthetic method of phosphorus-containing intermediate is the same as embodiment 1.

[0038] Step 2: Add SPDPC 29.7g and 100ml of acetonitrile to a 250ml three-neck flask equipped with magnetic stirring, dropping funnel and thermometer, add 10.5ml of ethylenediamine to the dropping funnel and dilute with 40ml of acetonitrile until the temperature rises to 50 After 1.5 hours of dropping, keep the temperature at 70°C until no HCl gas is released, then slowly cool down to room temperature, filter, wash with dichloromethane for several times, and dry at 50°C to obtain a slightly Pale yellow powdery solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com