Arginine deiminase high-yielding Bacillus cereus and application thereof

An arginine deiminase, Bacillus cereus technology, applied in bacteria, microorganism-based methods, microorganisms, etc., can solve the problem that the enzymatic activity does not reach the ideal industrial level, etc., and achieves short fermentation culture time, separation The effect of low purification cost and high product concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Obtaining of mutant strains

[0035] 1. Preparation of Type-Based Strains

[0036] Take a strain of Bacillus cereus obtained from the soil as the starting strain, insert it into a medium containing 100ml, cultivate it at 30-37°C, 100-200r / min for 5-30h, then take 1ml of the bacterial solution and add it to 9ml of sterile water, mix well, dilute the concentration to 10 times, continue to dilute 10 times in this way -2 , 10 -3 and 10 -4 times, and the bacterial solution is set aside.

[0037] The composition of the culture medium is: 0.1-10% peptone, 0.1-5% yeast powder, 0.1-10% sodium chloride, the balance is deionized water, and the pH is 6.0-7.5.

[0038] 2. N ion beam mutagenesis

[0039] Take 0.5ml of the bacterial solution prepared in step 1, apply it to a sterile petri dish and dry it, and use a TITAN ion beam implanter to perform N ion beam implantation on the bacteria with an energy of 30keV and an injection dose of 1-5×10 15 ion / cm 2 , after inj...

Embodiment 2

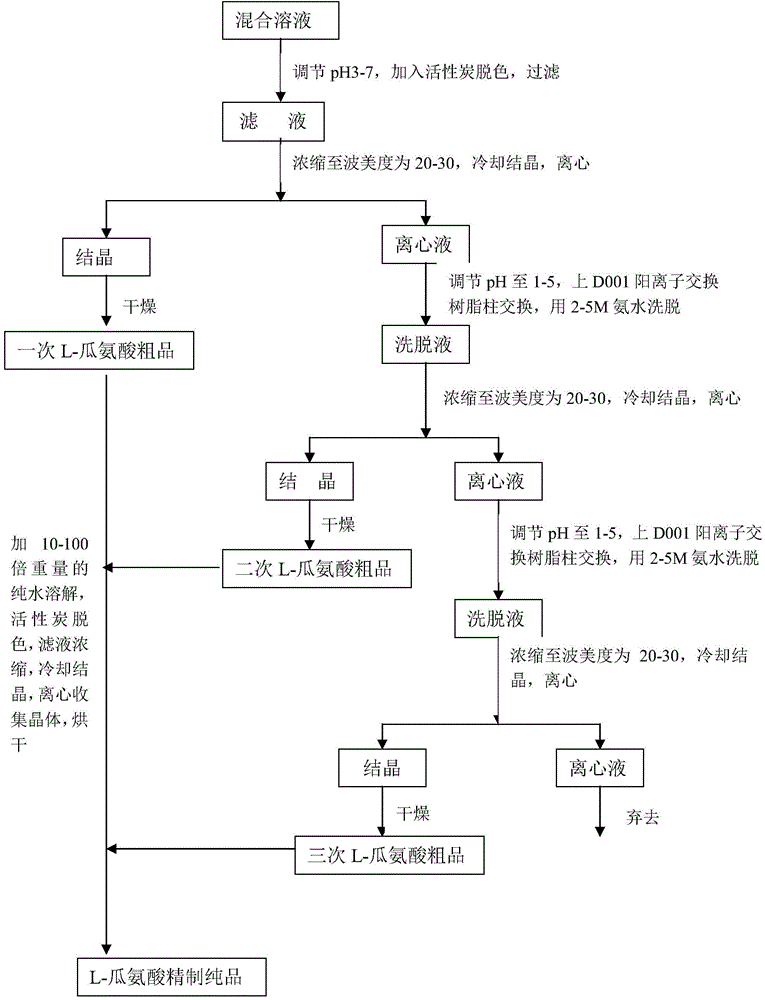

[0049] The production method of embodiment 2 L-citrulline

[0050] 1. Culture of strains

[0051] Including seed culture and fermentation culture, the specific steps are as follows:

[0052] (1) Primary seed cultivation:

[0053] Primary seed medium: 1% peptone, 0.5% yeast powder, 1% sodium chloride, 1% glycerin, the balance is deionized water, and the pH is 7.

[0054] Cultivation method: Take a glycerol tube to store the bacteria, place it at room temperature until it melts, draw 500ul of the bacteria solution into the first-level seed shake flask, and culture at 37°C for 15 hours at 200r / min.

[0055] (2) Secondary seed cultivation:

[0056] Secondary seed medium: 1% glycerin, 4% corn steep liquor, 0.5% arginine, the balance is deionized water, pH is 7.

[0057] Cultivation method: Inoculate the primary seeds into a 30L secondary seed tank at a volume ratio of 5%, and cultivate for 15 hours at 200r / min.

[0058] (3) Fermentation culture

[0059] 2% glycerin, 2% corn s...

Embodiment 3

[0072] The production method of embodiment 3 L-citrulline

[0073] 1. Culture of strains

[0074] (1) Primary seed cultivation:

[0075] Primary seed medium: 0.1% peptone, 5% yeast powder, 0.1% sodium chloride, 0.1% glycerol, the balance is deionized water, pH 6.

[0076] Cultivation method: Take a glycerol tube to store the bacteria, place it at room temperature until it melts, draw 100ul of the bacteria solution into the first-level seed shaker flask, and cultivate at 100r / min at 30°C for 16h.

[0077] (2) Secondary seed cultivation:

[0078] Secondary seed medium: 5% glycerin, 5% corn steep liquor, 5% arginine, the balance is deionized water, pH 6.

[0079] Cultivation method: inoculate primary seeds into secondary seed tanks at a volume ratio of 1%, and cultivate for 16 hours at 100 r / min.

[0080] (3) Fermentation culture

[0081] 0.1% glycerin, 5% corn steep liquor, 0.1% arginine, 0.1% magnesium sulfate, the balance is deionized water, the pH is 6.

[0082] Cultiva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com