Improved nano porous copper thin film and preparation method thereof

A nanoporous copper and thin film technology, applied in the field of nanomaterials, can solve problems such as poor battery life, achieve and stabilize electrochemical cycle performance, simple operation process, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

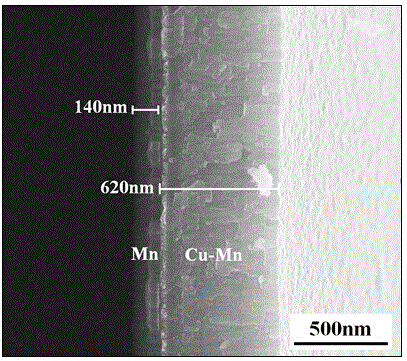

[0027] Put the pure manganese target and the copper-manganese alloy target (the chemical composition is expressed in atomic %: Cu: 30; Mn: 70) into the target position in the chamber of the magnetron sputtering film forming instrument, and put the clean single crystal silicon Fix the film on the tray directly above the target position, close the chamber and start vacuuming, and the vacuum degree of the chamber is pumped to 1.5×10 -4 After Pa, set the sputtering conditions as sputtering power DC 50 W, Ar gas pressure 0.5 Pa. Turn on the pure manganese target to start sputtering, and stop the pure manganese sputtering after 10 minutes. At this time, a layer of pure manganese film is prepared on the silicon wafer with a thickness of 140 nm; then turn on the copper-manganese target and start sputtering, 50 minutes Finally stop the copper-manganese sputtering, at this time a layer of copper-manganese alloy film is formed on the pure manganese film with a thickness of 620 nm; the S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com