Strengthened composite layer on rotor surface of screw drilling tool and machining process thereof

A technology for rotor surface and screw drilling tools, which is applied to layered products, earth-moving drilling, drilling equipment, etc. Service life, low porosity, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

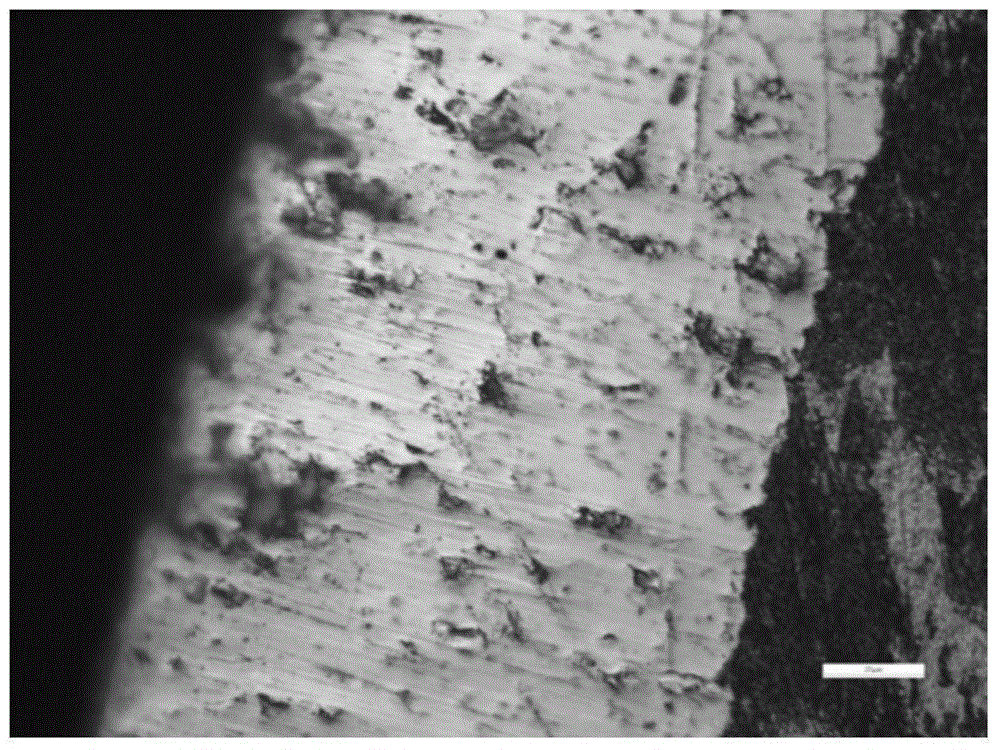

[0034] Embodiment 1 Electroplating strengthening composite layer (milky white chrome layer-hard chrome layer)

[0035] The chemical composition of the electroplating bath solution for electroplating the milky white chromium layer and the hard chromium layer is: chromic anhydride 230-280g / L, sulfuric acid 2.3-2.8g / L, trivalent chromium 3-8g / L. First, electroplate the milky white chrome layer on the surface of the screw drill rotor, and the process parameters of the electroplating milky white chrome layer are: temperature 70-75°C, cathode current density 15-25A / dm 2 , coating thickness 0.02-0.06mm. Then electroplate a hard chromium layer on the surface of the screw drill rotor, and the process parameters of electroplating hard chromium layer: temperature 52-55℃, cathode current density 35-40A / dm 2 , coating thickness 0.10-0.15mm. Metallographic examination results show that a dense opalescent chromium layer is formed adjacent to the substrate. The wear amount of the wet sand ...

Embodiment 2

[0037] Embodiment 2 Electroplating strengthening composite layer (milky white chrome layer-hard chrome layer)

[0038] The chemical composition of the electroplating bath solution for electroplating milky white chrome layer and hard chrome layer is: chromic anhydride 230-280g / L, sulfuric acid 2.3-2.8g / L, trivalent chromium 3-8g / L, hard chrome additive 20mL / L. First, electroplate the milky white chrome layer on the surface of the screw drilling tool rotor, and the process parameters of the milky white chrome layer are: temperature 80-85°C, cathode current density 15-25A / dm 2, coating thickness 0.02-0.06mm. Then electroplate a hard chromium layer on the surface of the screw drill rotor, and the process parameters of electroplating hard chromium layer: temperature 60-65℃, cathode current density 35-40A / dm 2 , coating thickness 0.10-0.15mm. The results of metallographic examination show that a dense opalescent chromium coating is formed adjacent to the substrate. Wear test and ...

Embodiment 3

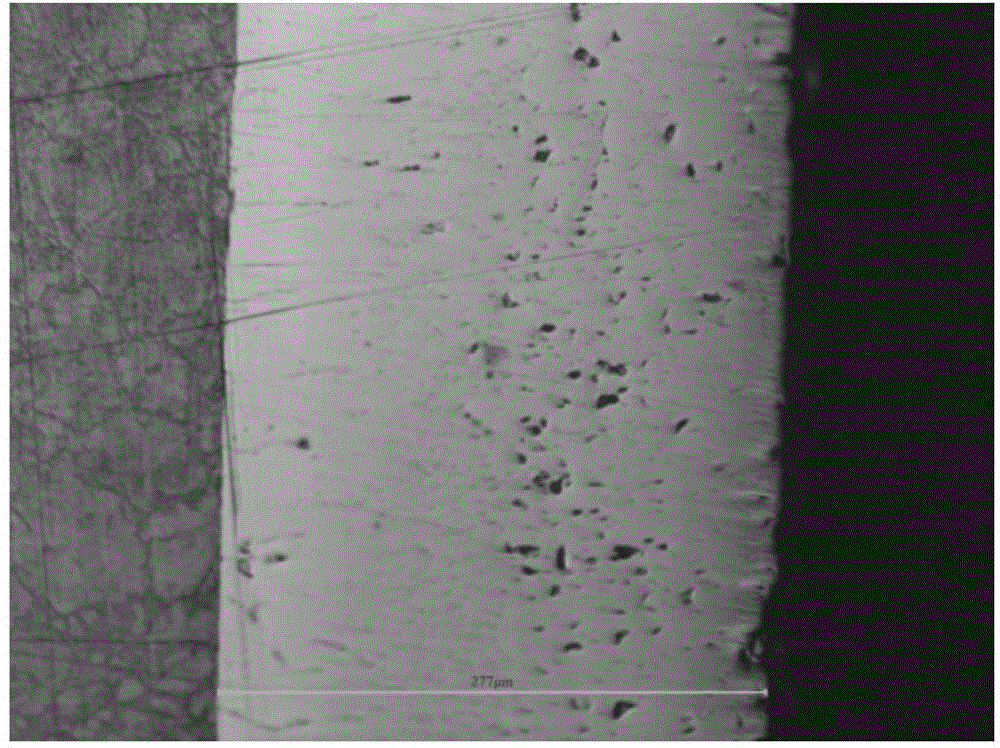

[0039] Embodiment 3 Electroplating strengthening composite layer (double nickel-hard chromium layer)

[0040] First electroplate the semi-bright nickel layer, the chemical composition of the electroplating bath is: nickel sulfate 280-320g / L, nickel chloride 38-47g / L, boric acid 45-50g / L, wetting agent (sodium lauryl sulfate) 1-3mL / L, appropriate amount of brightener (butynediol), process parameters: temperature 52±2°C, cathode current density 2.5-4.5A / dm 2 , pH3.6-4.5, coating thickness 0.02-0.05mm;

[0041] Then electroplate the bright nickel layer, the chemical composition of the electroplating bath solution is: nickel sulfate 200-240g / L, nickel chloride 75-150g / L, wetting agent (2-ethylhexyl sodium sulfate) 1-3mL / L, bright Agent (propoxybutynediol) 5-40mL / L, process parameters: temperature 52±2℃, cathode current density 3-5A / dm 2 , pH3.5-4.4, coating thickness 0.005-0.03mm;

[0042] Finally, the hard chromium layer is electroplated. The chemical composition of the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com