Method for separating total flavonoid glucuronide and total phenylethanoid glycoside in Callicarpa kwangtungensis Chun

A technology for the separation of glucuronides and glucuronides, which is applied in the field of separation of total flavonoid glucuronides and total phenylethanol glycosides in Guangdong Zizhu, and can solve the problem of the importance of total flavone glucuronides and the insufficient purity of total phenylethanol glycosides , mixed with other problems, to achieve excellent water solubility, light yellow color, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this example, the steps for separating and enriching total flavone glucuronides and total phenylethanol glycosides from Guangdong Zizhu are as follows:

[0053] (1) Take the aboveground parts of Guangdong Zizhu and dry them, crush them through a 30-mesh sieve, add water 10 times the mass of the powder, reflux and extract twice, each time for 2 hours, filter, combine the extracts, and concentrate under reduced pressure to a crude drug content of 10g / mL Concentration, get concentrated solution;

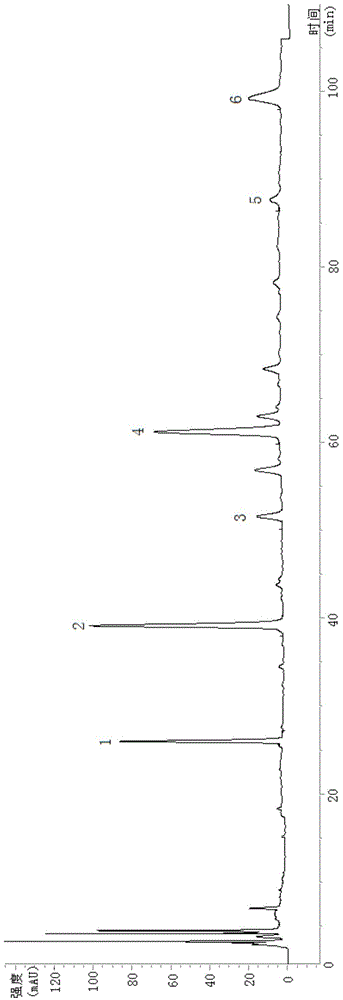

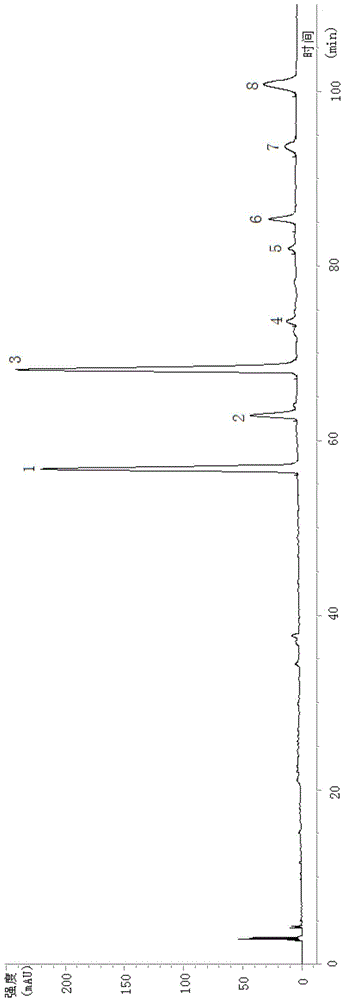

[0054] (2) AB-8 macroporous adsorption resin is applied to the concentrated solution, the sample volume is 2 times the column volume, and the impurity is eluted with 5 times the column volume of water, and then 4 times the column is eluted with 20% ethanol aqueous solution with a volume percent concentration Volume, flow rate 5BV / h, the eluate is concentrated under reduced pressure to no alcohol smell, and freeze-dried to obtain the total flavonoid glucuronide part, wherein th...

Embodiment 2

[0062] In this example, the steps for separating and enriching total flavone glucuronides and total phenylethanol glycosides from Guangdong Zizhu are as follows:

[0063] (1) Take the aboveground part of Guangdong purple pearl and dry it, crush it through a 10-mesh sieve, add 10 times the mass of the powder into an aqueous ethanol solution with a volume percentage concentration of 60%, and reflux for extraction twice, each time for 2 hours, filter, combine the extracts, and reduce Concentrate under pressure to the concentration of crude drug amount 1g / mL to obtain concentrated solution;

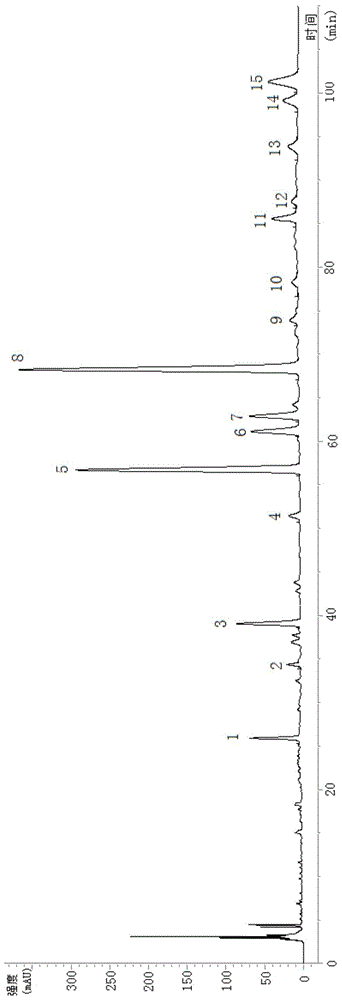

[0064] (2) Put the concentrated solution on D101 macroporous adsorption resin, the sample volume is 1 / 2 times the column volume, wash with 5 times the column volume of water to remove impurities, and then elute with 25% ethanol aqueous solution for 3 times Column volume, flow rate 3BV / h, concentrating the eluate under reduced pressure until it has no alcohol smell, and freeze-drying to obtain...

Embodiment 3

[0068] In this example, the steps for separating and enriching total flavone glucuronides and total phenylethanol glycosides from Guangdong Zizhu are as follows:

[0069] (1) Take the underground part of Guangdong Zizhu and dry it, crush it through a 10-mesh sieve, add 10 times the mass of the powder to 60% ethanol aqueous solution for reflux extraction twice, each time for 2 hours, filter, combine the extracts, reduce Concentrate under pressure to the concentration of crude drug amount 3g / mL to obtain concentrated solution;

[0070] (2) Put the concentrated solution on the D101 macroporous adsorption resin, the sample volume is 1 times the column volume, eluted with 4 times the column volume of water to remove impurities, and then eluted with 20% ethanol aqueous solution for 3 times the column volume Concentrate the eluent under reduced pressure at a flow rate of 3BV / h until there is no alcohol smell, freeze-dry to obtain the total flavonoid glucuronide fraction, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com