Resin composition and application thereof

A technology of resin composition and active ingredients, which is applied in the direction of synthetic resin layered products, laminated, layered products, etc., can solve the problems of unable to meet the application requirements of high-speed signal transmission, signal distortion, and slow signal transmission rate, etc. Achieve the effects of excellent electrical properties, low loss factor, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

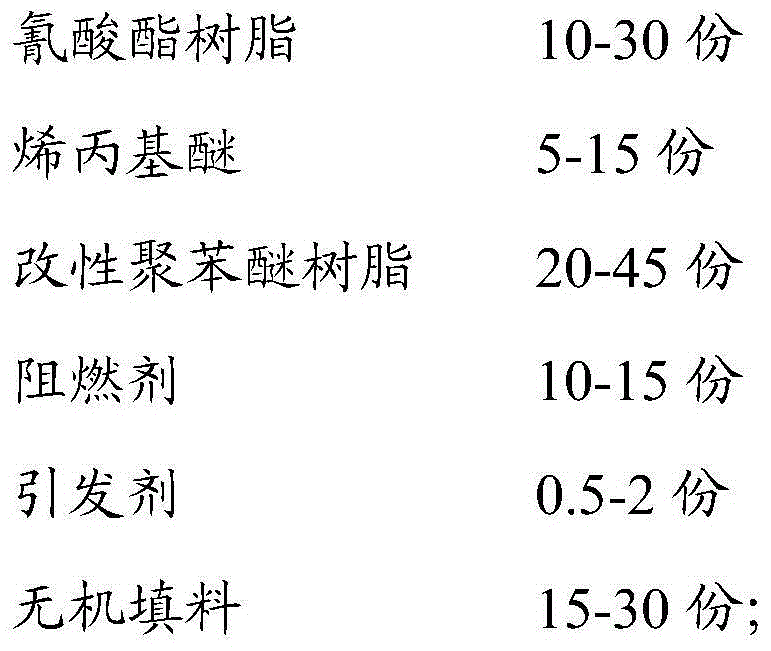

Method used

Image

Examples

Embodiment 1

[0030] A resin composition in this embodiment is composed of 65wt% active ingredients and 35wt% solvent (butanone). The active ingredients include the following raw materials in parts by weight: 20 parts of bisphenol A type cyanate, 10 parts of three Methylol propane diallyl ether, 28 parts of allyl polyphenylene ether (weight average molecular weight: 2000), 12 parts of decabromodiphenylethane, 1 part of dicumyl peroxide and 29 parts of silicon micropowder.

[0031] Use 2116 glass fiber cloth to impregnate the above resin composition, and bake at 160°C for 190s to make a prepreg. The resin content of the prepreg was 50%, and the resin fluidity was 20%.

[0032] Take 6 pieces of prepreg and stack them up, with 1HZ electrolytic copper foil on both sides, then clamp them between two steel plates, place them in a vacuum press, and heat them at 200°C and 35Kg / cm 2 Under conditions. Hot pressing for 2h to make a double-sided copper clad board. The test results are shown in Table...

Embodiment 2

[0034] The present embodiment is a kind of resin composition, is made up of 60wt% active ingredient and 40wt% solvent (butanone), and described active ingredient comprises following raw material by weight: 15 parts of bisphenol A type cyanate, 15 parts of three Methylol propane diallyl ether, 28 parts of allyl polyphenylene ether (weight average molecular weight: 1500), 12 parts of decabromodiphenylethane, 1 part of dicumyl peroxide and 29 parts of silicon micropowder.

[0035] Use 2116 fiberglass cloth to impregnate the above resin composition, and bake at 160°C for 180s to make a prepreg. The resin content of the prepreg was 50%, and the resin fluidity was 20%.

[0036] Take 6 pieces of prepreg and stack them up, with 1HZ electrolytic copper foil on both sides, then clamp them between two steel plates, place them in a vacuum press, and heat them at 200°C and 35Kg / cm 2 Under conditions. Hot pressing for 2h to make a double-sided copper clad board. The test results are show...

Embodiment 3

[0038] A kind of resin composition of the present embodiment is made up of the active ingredient of 55wt% and the solvent (cyclohexanone) of 45wt%, and described active ingredient comprises the raw material of following weight portion: 15 parts of bisphenol A type cyanate, 10 parts Pentaerythritol triallyl ether, 33 parts of terminal allyl polyphenylene ether (weight average molecular weight: 2500), 12 parts of decabromodiphenylethane, 1 part of dicumyl peroxide and 29 parts of silicon micropowder.

[0039] Use 2116 fiberglass cloth to impregnate the above resin solution, and bake at 160°C for 160s to make a prepreg. The resin content of the prepreg was 50%, and the resin fluidity was 20%.

[0040] Take 6 pieces of prepreg and stack them up, with 1HZ electrolytic copper foil on both sides, then clamp them between two steel plates, place them in a vacuum press, and heat them at 200°C and 35Kg / cm 2 Under conditions. Hot pressing for 2h to make a double-sided copper clad board....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com