Pavement tail gas degradation fog sealing layer material and preparation method thereof

A fog sealing layer material and tail gas degradation technology, applied in the field of tail gas degradation fog sealing layer material and its preparation, to achieve the effects of easy availability of raw materials, good market prospects, promotion and evaluation, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

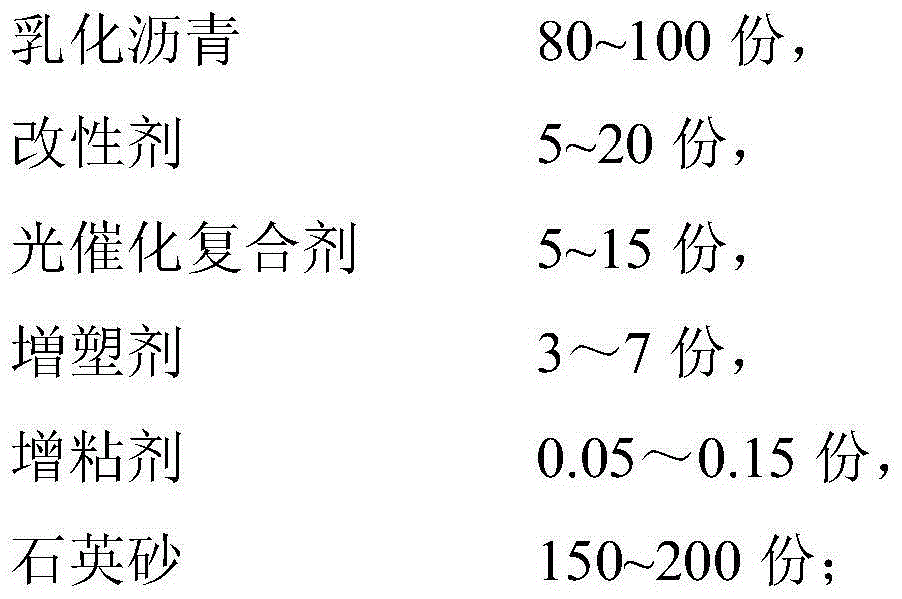

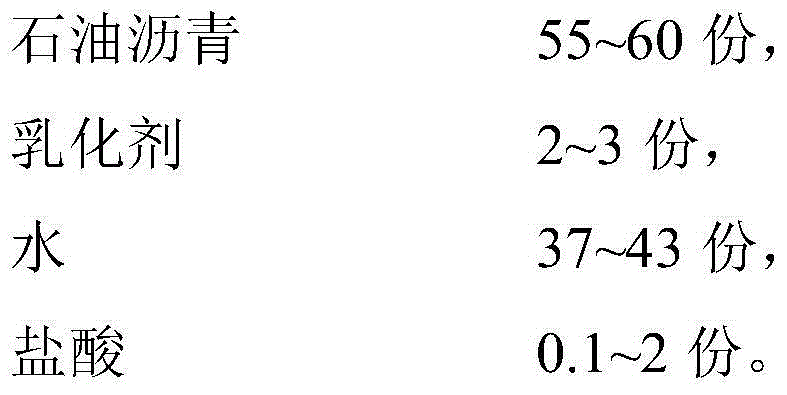

Method used

Image

Examples

Embodiment 1

[0029] First take road petroleum asphalt SK90 # 60 parts, put into the melting furnace to melt, dehydrate, remove impurities, and then keep warm at 120°C for later use;

[0030] Separately mix 37 parts of water with 3 parts of quaternary ammonium salt emulsifier, add appropriate amount of hydrochloric acid, adjust the pH to about 1.5, and then heat it to 75°C, then mix the heated emulsifier aqueous solution with asphalt, and put it into the emulsification In the machine, the material can be filtered and discharged after pressurization, shearing and grinding for 10-15 minutes, and the outlet temperature of the emulsified asphalt should not be higher than 85°C during the process;

[0031] Add 10 parts by weight of natural rubber latex (NR) into 90 parts of emulsified asphalt, stir at a low speed for 6-25 minutes, and stir evenly to obtain modified emulsified asphalt;

[0032] Take 100 parts of modified emulsified asphalt, and pour 15 parts of photocatalytic composite agent anat...

Embodiment 2

[0034] First, take 35 parts of 60# petroleum asphalt and 15 parts of 10# petroleum asphalt and add them to the melting pot to melt, dehydrate, remove impurities, and then keep warm at 140°C for later use;

[0035] Add another 50 parts of water into the emulsification kettle, heat up to about 60°C, add 5 parts of ethylene oxide diamine emulsifier, stir and mix evenly, add appropriate amount of hydrochloric acid, adjust the pH to about 2, and slowly add After the melted asphalt is added, stir for 10-15 minutes to filter and discharge;

[0036] Add 10 parts by weight of ethylene-vinyl acetate copolymer emulsion (EVA) to 95 parts of emulsified asphalt, stir at a low speed for 6-25 minutes, and stir evenly to obtain modified emulsified asphalt;

[0037] Take 100 parts of modified emulsified asphalt, and pour 15 parts of photocatalytic material rutile TiO 2 , continue stirring at room temperature at a speed of 300-400rpm, after about 40 minutes of stirring evenly, pour 7 parts of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com