Reutilization of Bundt Salt in A Sodium Sodium Waste Residue

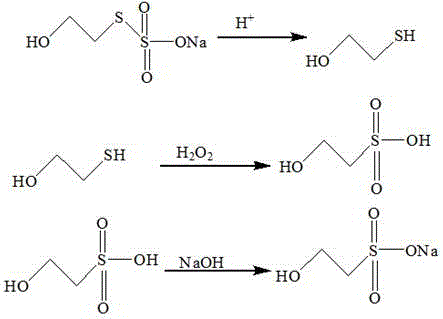

A technology for hydrosulfite and waste residue, which is applied in the preparation of sulfonates, etc., can solve the problems of inability to recycle organic matter, expensive investment, and no conversion and utilization of high value-added products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] (1) Weigh 100g of Bunter's salt into a round bottom flask, add 100g of water to dissolve, take 30mL of hydrochloric acid solution with a mass fraction of 10% and drop it into the flask while stirring, and control the acid hydrolysis temperature at 85-90°C, Reaction time 3h;

[0013] (2) Cool the solution after acid hydrolysis, control the temperature at 10-15°C, slowly add 80g of hydrogen peroxide dropwise, and control the reaction time to 3h after the dropwise addition;

[0014] (3) After the reaction, add sodium hydroxide into the reaction bottle for neutralization, and the quality of adding sodium hydroxide is 30g;

[0015] (4) Slowly add 100mL of ethanol to the neutralized solution, and a white flocculent precipitate will slowly wash out from the solution, which is sodium isethionate. The precipitate was suction filtered, washed, and dried. The weight m=64g, the yield was 78%, and the product purity was 98%.

Embodiment 2

[0017] (1) Weigh 100g of Bunter's salt into a round bottom flask, add 100g of water to dissolve, take 20mL of sulfuric acid solution with a mass fraction of 30% and drop it into the flask while stirring, and control the acid hydrolysis temperature at 85-90°C. Reaction time 3h;

[0018] (2) Cool the solution after acid hydrolysis, control the temperature at 10-15°C, slowly add 60g of hydrogen peroxide dropwise, and control the reaction time to 2.5h after the dropwise addition;

[0019] (3) After the reaction, add sodium hydroxide into the reaction bottle for neutralization, and the quality of adding sodium hydroxide is 30g;

[0020] (4) Slowly add 100mL of ethanol to the neutralized solution, and a white flocculent precipitate will slowly wash out from the solution, which is sodium isethionate. The precipitate was suction filtered, washed, and dried. The weight m=69g, the yield was 84%, and the product purity was 97%.

Embodiment 3

[0022] (1) Weigh 100g of Bunter's salt into a round bottom flask, add 100g of water to dissolve, take 20mL of nitric acid solution with a mass fraction of 20% and drop it into the flask while stirring, and control the acid hydrolysis temperature at 70-75°C. Reaction time 1.5h;

[0023] (2) Cool the solution after the acid hydrolysis, control the temperature at 10-15°C, slowly add 50g of hydrogen peroxide dropwise, and control the reaction time to 1.5h after the dropwise addition;

[0024] (3) After the reaction, add potassium hydroxide into the reaction flask for neutralization, and the quality of adding potassium hydroxide is 40g;

[0025] (4) Slowly add 200mL of ethanol to the neutralized solution, and a white flocculent precipitate will slowly wash out from the solution, which is sodium isethionate. Suction filter, wash and dry the precipitate, the weight m=72g, the yield is 87%, and the product purity is 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com