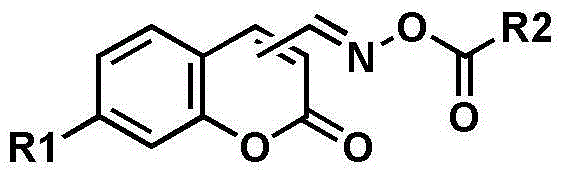

Coumarin oxime ester photoinitiator and preparation method thereof

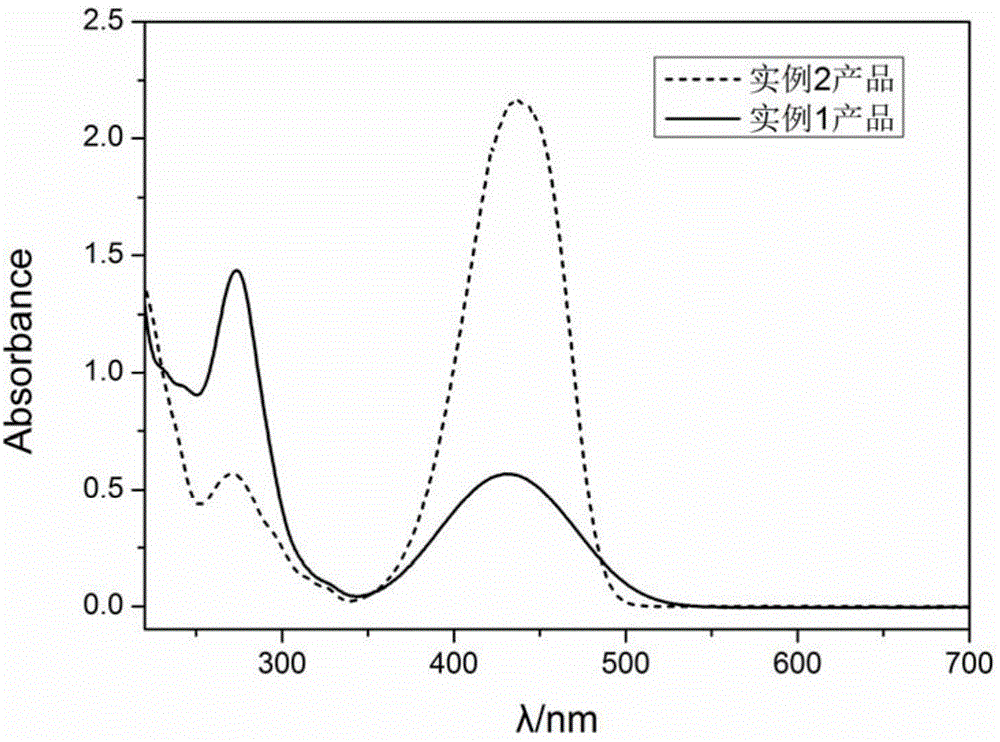

A technology of photoinitiator and coumarin oxime, which is applied in the field of photoinitiator containing coumarin structural unit and oxime ester group and its preparation, can solve the problem of hindering the development of oxime ester initiators, inability to match LED light sources, Curing material surface damage and other problems, to achieve the effect of easy implementation, mature preparation method and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]

[0045] The preparation of photoinitiator A1-1, concrete preparation steps are as follows:

[0046] (1) In a 250mL three-necked flask with a condenser tube, 4.62g of 4-methyl-7-diethylaminocoumarin and 3.3g of selenium dioxide were dissolved in 120mL of xylene, and the whole system was N 2 Under protection, stirred and reacted at 130°C for 12h; filtered off the solid residue in the mixture while it was hot, and spin-dried the solvent to obtain a crude product; the crude product was separated by silica gel column chromatography (petroleum ether:ethyl acetate=5:1) Purification afforded red solid B-1. Yield: 74%.

[0047] NMR: 1 H NMR (400MHz, CDCl 3 )δ10.06(s, 1H), 8.33(d, J=9.2Hz, 1H), 6.66(dd, J=9.2, 2.6Hz, 1H), 6.55(d, J=2.6Hz, 1H), 6.48( s, 1H), 3.46 (q, J = 7.1 Hz, 4H), 1.25 (t, J = 7.1 Hz, 6H).

[0048] (2) In a 25mL three-necked flask with a condenser tube, 0.163g of B-1 and 0.072g of NH 2 OH·HCl was dissolved in 10mL of absolute ethanol, under N 2 Stir...

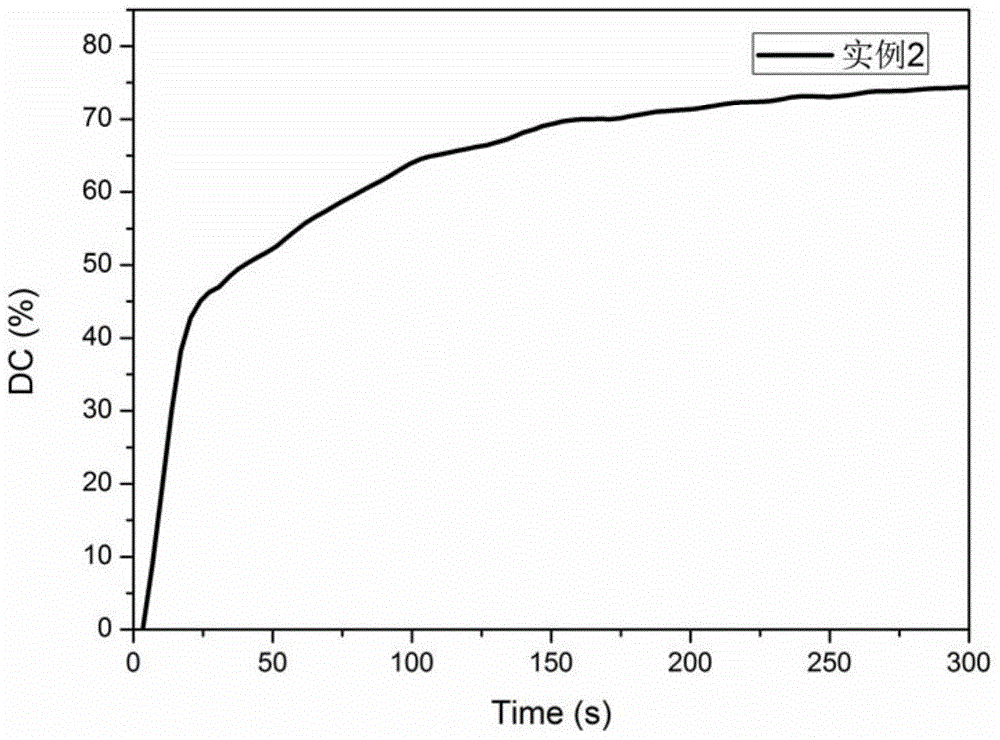

Embodiment 2

[0053]

[0054] The preparation of photoinitiator A2-1, concrete preparation steps are as follows:

[0055] (1) In a 100mL three-neck flask with a condenser tube, dissolve 1.93g of 4-diethylamino salicylaldehyde, 3.2g of diethyl malonate and 1mL of piperidine in 30mL of absolute ethanol, and N 2 Under protection, stir, and react at 75°C for 6 hours; spin dry ethanol to obtain the intermediate product, add it to a 100mL three-neck flask with a condenser tube, add 20mL concentrated hydrochloric acid and 20mL glacial acetic acid to the bottle, N 2 Under protection, heat up to 100°C and stir for 6h; then cool the mixture to room temperature, pour it into 100mL of ice water, adjust its pH value to about 5 with 40% sodium hydroxide solution, a light yellow solid precipitates, continue to stir for 30min The solid crude product was obtained by filtration, washed several times with water, rinsed several times with absolute ethanol, and dried to obtain pure product C, yield: 86%.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com