PVC (polyvinyl chloride)-base wood-plastic composite material and preparation method thereof

A wood-plastic composite material and wood powder technology, applied in the field of PVC-based wood-plastic composite material and its preparation, can solve the problems of poor mechanical properties and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

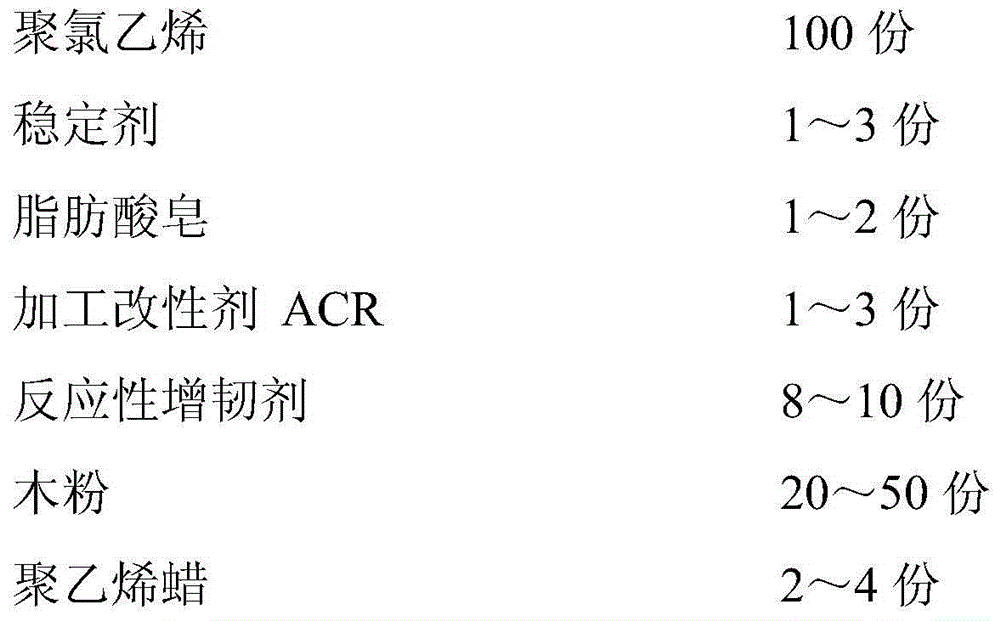

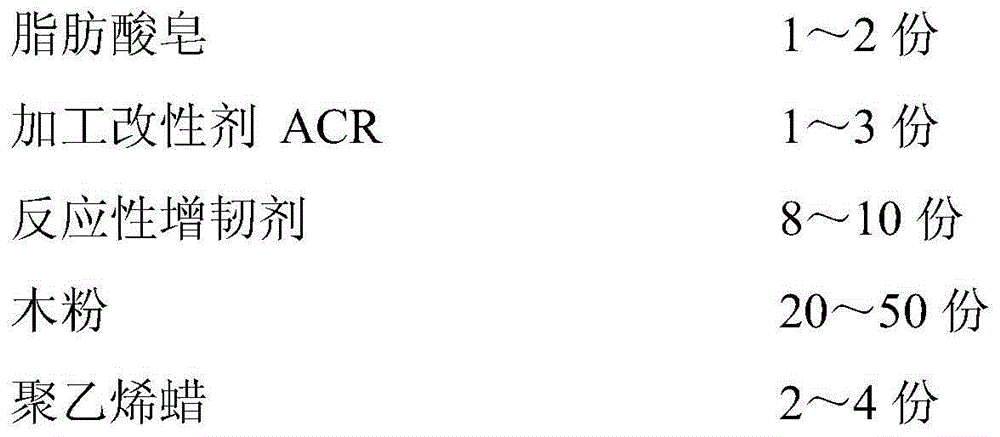

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the acrylic core-shell structure latex particles containing active groups on the surface includes: adding 80-200 parts by weight of water, 2-10 parts by weight of emulsifier and 0.1-1 part by weight of initiator into the reaction kettle , heat up to 40-80°C, then add 60-90 parts by weight of polyacrylate rubber to the reactor for polymerization, and then add 7-30 parts by weight of methyl methacrylate, 3-10 parts by weight of The second monomer was reacted for 2 hours, filtered, coagulated, and dried to obtain acrylate core-shell latex particles with active groups on the surface. The emulsifier is not particularly limited, and is preferably one or more of potassium oleate, potassium stearate, disproportionated potassium abietate or sodium dodecylbenzenesulfonate. The initiator is not particularly limited, preferably potassium persulfate, benzoyl peroxide or azobisisobutyronitrile.

[0031] According to the present invention, the wood powder is...

Embodiment 1

[0036] Add 80 parts of water, 2-parts of emulsifier potassium stearate and 0.1 part of initiator potassium persulfate into the reactor, raise the temperature to 40°C, then add 60 parts of polyacrylate rubber to the reactor for polymerization, and then add Add 7 parts of methyl methacrylate and 3 parts of glycidyl methacrylate dropwise into the reaction kettle, react for 2 hours, filter, coagulate, and dry to obtain acrylate core-shell latex particles ACR1 with active groups on the surface.

Embodiment 2

[0038] Add 150 parts of water, 5 parts of emulsifier potassium oleate and 0.5 parts of initiator benzoyl peroxide into the reactor, raise the temperature to 60°C, then add 75 parts of polyacrylate rubber to the reactor for polymerization, and then add 20 parts of methyl methacrylate and 5 parts of maleic anhydride were added dropwise into the reaction kettle, reacted for 2 hours, filtered, coagulated, and dried to obtain acrylate core-shell latex particles ACR2 with active groups on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com