Tin oxide alumina-based low-concentration acetone gas sensor and preparation method thereof

A gas sensor, alumina-based technology, used in instruments, scientific instruments, measuring devices, etc., can solve the problems of low detection limit of acetone, limited practical application of acetone sensor, short response time, etc., and achieves pollution-free carry and low cost. , The effect of fast response and recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

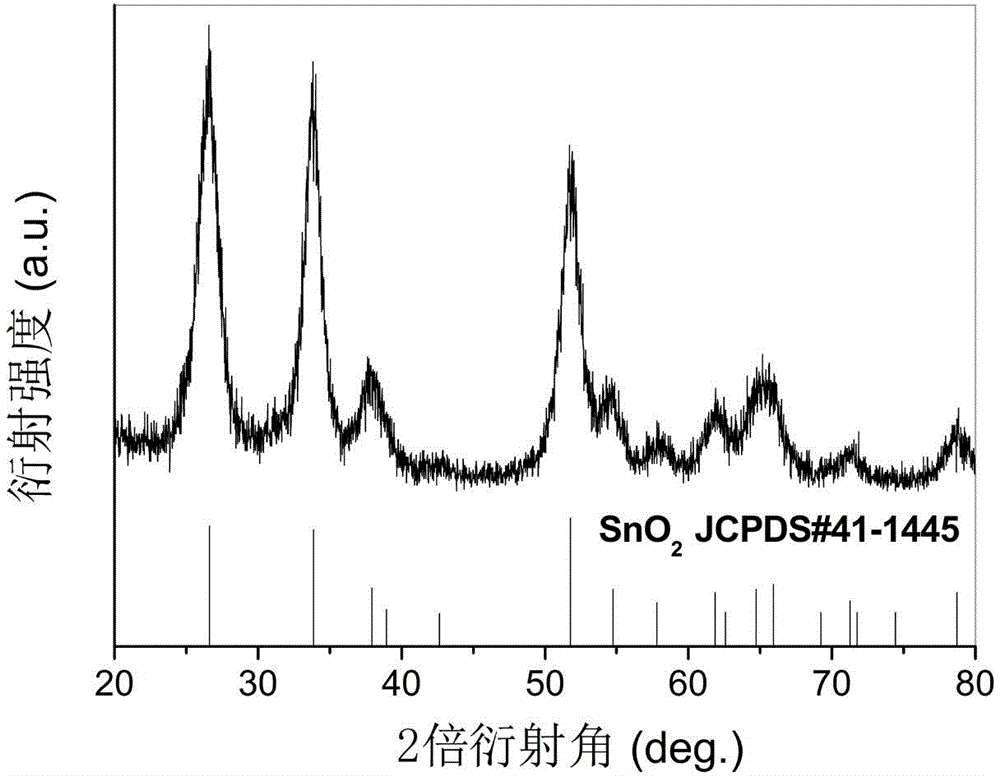

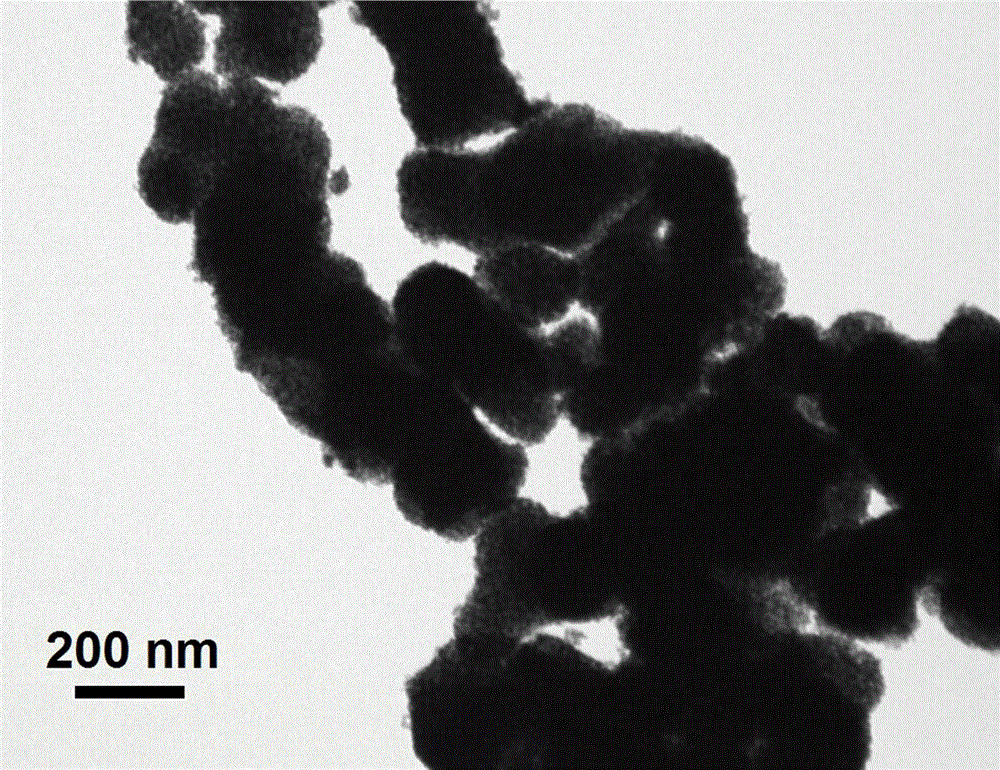

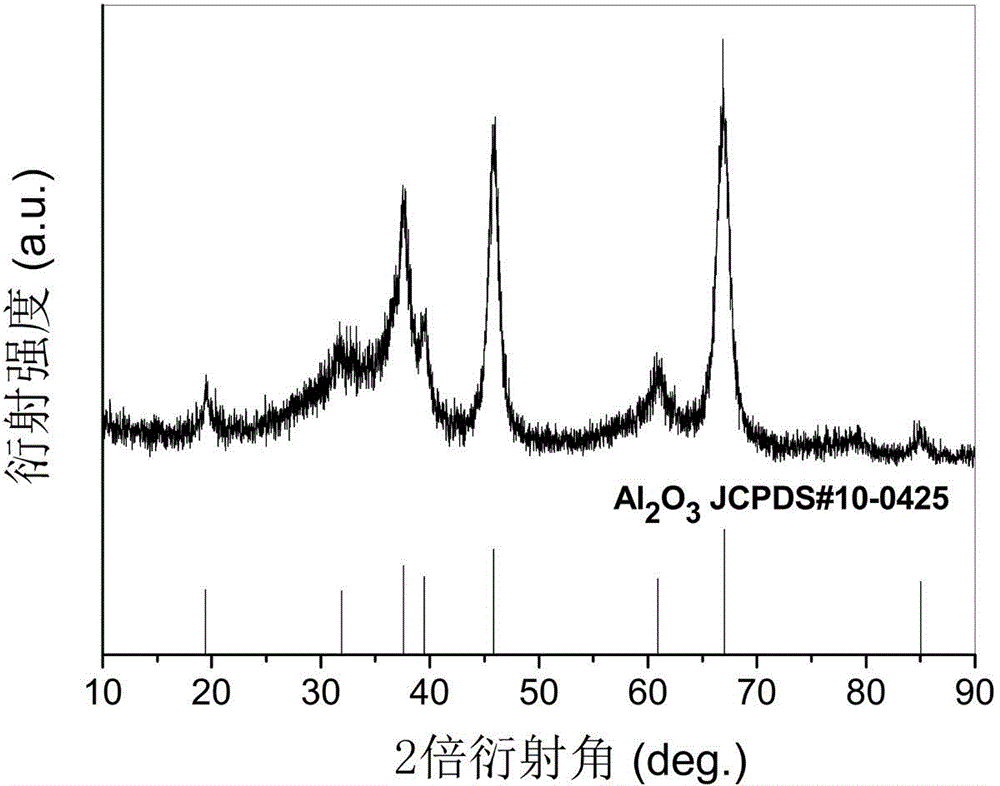

[0022] (1) Nanoporous SnO doped with Pt in the inner layer 2 Preparation of base material: weigh 3 g SnCl 4 ·5H 2 O was dissolved in 15 ml deionized water and 15 ml absolute ethanol, and then 6 g CO(NH 2 ) 2 And 1 g (NH 4 ) 2 SO 4 After 3 hours of magnetic stirring, a uniform and clear precursor solution is obtained; the reaction solution is transferred to the inner lining of a 50 ml hydrothermal reaction vessel, the reaction vessel is screwed and sealed, and reacted in an oven at 100 ℃ for 24 hours; cooled to room temperature and centrifuged , Wash the precipitate with deionized water and absolute ethanol several times, and place it in an oven at 60 ℃ to dry overnight to obtain a solid precursor; place the precursor in a muffle furnace at 550 ℃ for 5 hours and grind with an agate mortar to obtain nano Porous SnO 2 material. Take H with a mass percentage of 1.0 wt% 2 PtCl 6 The solution is added dropwise to the prepared nanoporous SnO 2 The material is mixed uniformly, dried, a...

Embodiment 2

[0026] (1) Nanoporous SnO doped with Pt in the inner layer 2 Preparation of base material: weigh 3 g SnCl 4 ·5H 2 O was dissolved in 15 ml deionized water and 15 ml absolute ethanol, and then 5 g CO(NH 2 ) 2 And 2 g (NH 4 ) 2 SO 4 After 3 hours of magnetic stirring, a uniform and clear precursor solution is obtained; the reaction solution is transferred to the inner lining of a 50 ml hydrothermal reaction vessel, the reaction vessel is screwed and sealed, and reacted in an oven at 110 ℃ for 20 hours; cooled to room temperature and centrifuged , Wash the precipitate with deionized water and absolute ethanol several times, and place it in an oven at 60 ℃ to dry overnight to obtain a solid precursor; place the precursor in a muffle furnace at 550 ℃ for 5 hours and grind with an agate mortar to obtain nano Porous SnO 2 material. Take 0.5 wt% of H 2 PtCl 6 The solution is added dropwise to the prepared nanoporous SnO 2 The material is mixed uniformly, dried, and fired at 500°C for 1 ...

Embodiment 3

[0030] (1) Nanoporous SnO doped with Pt in the inner layer 2 Preparation of base material: weigh 3 g SnCl 4 ·5H 2 O was dissolved in 15 ml deionized water and 15 ml absolute ethanol, and then 4 g CO(NH 2 ) 2 And 3 g (NH 4 ) 2 SO 4 After 3 hours of magnetic stirring, a uniform and clear precursor solution is obtained; the reaction solution is transferred to the inner lining of a 50 ml hydrothermal reaction vessel, the reaction vessel is screwed and sealed, and reacted in an oven at 105 ℃ for 22 hours; cooled to room temperature and centrifuged , Wash the precipitate with deionized water and absolute ethanol several times, and place it in an oven at 60 ℃ to dry overnight to obtain a solid precursor; place the precursor in a muffle furnace at 550 ℃ for 5 hours and grind with an agate mortar to obtain nano Porous SnO 2 material. Take H with a mass percentage of 0.1 wt% 2 PtCl 6 The solution is added dropwise to the prepared nanoporous SnO 2 The material is mixed uniformly, dried, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com