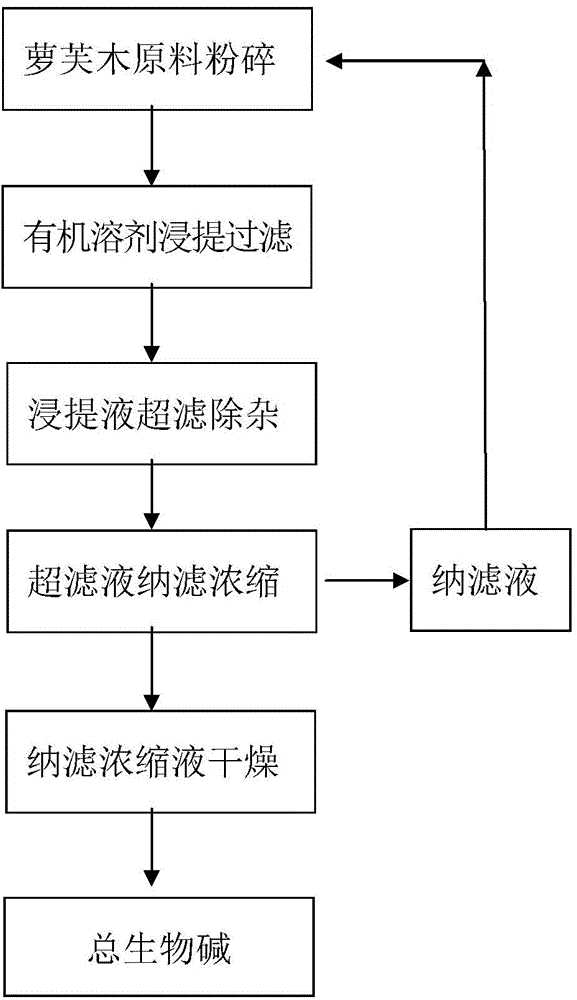

Membrane method for extracting total alkaloids from rauvolfia verticillata

A technology of Rauwolfia alkaloids and total alkaloids, which is applied in the field of medicine, can solve problems such as poor dissolution and processing performance, high labor and energy consumption, and slow disintegration of preparations, so as to reduce energy consumption, reduce waste water discharge, The effect of high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Extraction of Rauwolfia alkaloids: acid-alcohol liquid ultrasonic assisted extraction

[0042]1000g of Rauwolfia yunnanensis root powder crushed to 40 meshes was leached twice with the aid of ultrasonic wave with acidic ethanol with a solid-to-liquid ratio of 1:20. For the first time, add 10L of 70% acid ethanol water (containing 1% glacial acetic acid) leaching solution, first leaching at room temperature for 20 minutes, then ultrasonically assisted leaching for 20 minutes, ultrasonic power 250W, frequency 40kHz. Then let it stand for leaching for 20 minutes, and filter it with a synthetic fiber filter bag under normal temperature and pressure. The filter residue was leached once with 10L of the leaching solution, and the filtrate was combined for later use.

[0043] It should be noted that the above leaching method is ultrasonic-assisted leaching, and other leaching methods, such as percolation method and reflux method, may also be used. In addition, the selectio...

Embodiment 2

[0051] Mix 2000g of Rauvolwolfia yunnanensis roots and stems that have been crushed to 40 meshes, add 50% acid ethanol water (containing 0.5% hydrochloric acid) for 3 times and soak for 20 minutes, ultrasonically assisted extraction for 20 minutes, statically Place and extract for 20min. Filter and combine about 39L of extracts for later use.

[0052] The above-mentioned Rauwolfia extract was run through the ultrafiltration process. The material of the ultrafiltration membrane was polyethersulfone (PES), and the molecular weight cut-off was 20,000 Dalton. The working pressure is 0.5-0.6 MPa, and the working temperature is room temperature by using cold circulating water. When the solid liquid is concentrated to about 20% of the raw material liquid, the light transmittance of the ultrafiltrate is greater than 98%. The ultrafiltrate is taken for nanofiltration. The material of the nanofiltration membrane is polyamide (PA), the molecular weight cut-off is 250Da, the working pre...

Embodiment 3

[0055] 2000g of Rauvolwolfia yunnanensis leaves crushed to 40 meshes, moistened with a small amount of water first, added 80% acid methanol water (containing 0.25% sulfuric acid) for 3 times according to the ratio of solid to liquid 1:20, soaked for 20 minutes, and ultrasonically assisted extraction for 20 minutes , let stand for leaching for 20min. Filter and combine about 40L of extracts for later use.

[0056] The Rauwolfia extract is run through the ultrafiltration process. The ultrafiltration membrane is made of polyethersulfone (PES) with a molecular weight cut-off of 10,000 Dalton. The working pressure is 0.5-0.6MPa, and the working temperature is natural room temperature. When the solid liquid is concentrated to 15% of the raw material liquid, the ultrafiltrate is taken for nanofiltration. The nanofiltration membrane is made of sulfonated polyethersulfone (SPES) with a molecular weight cut-off of 200Da. The working pressure is 1.5-2.0MPa, using cold circulating wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com