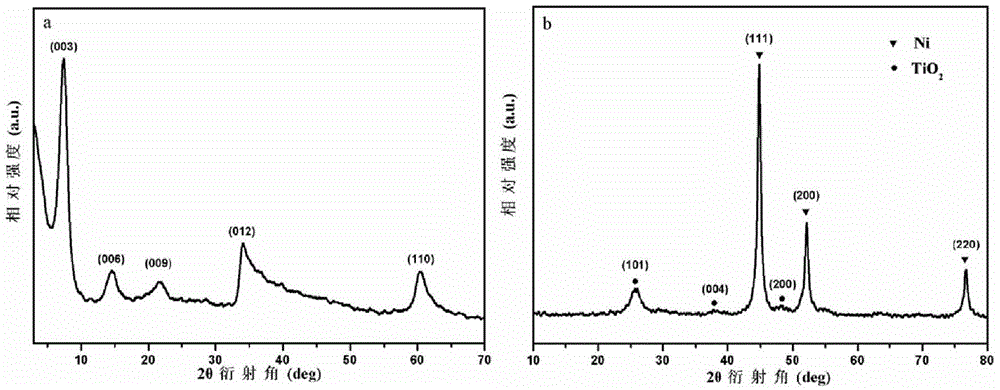

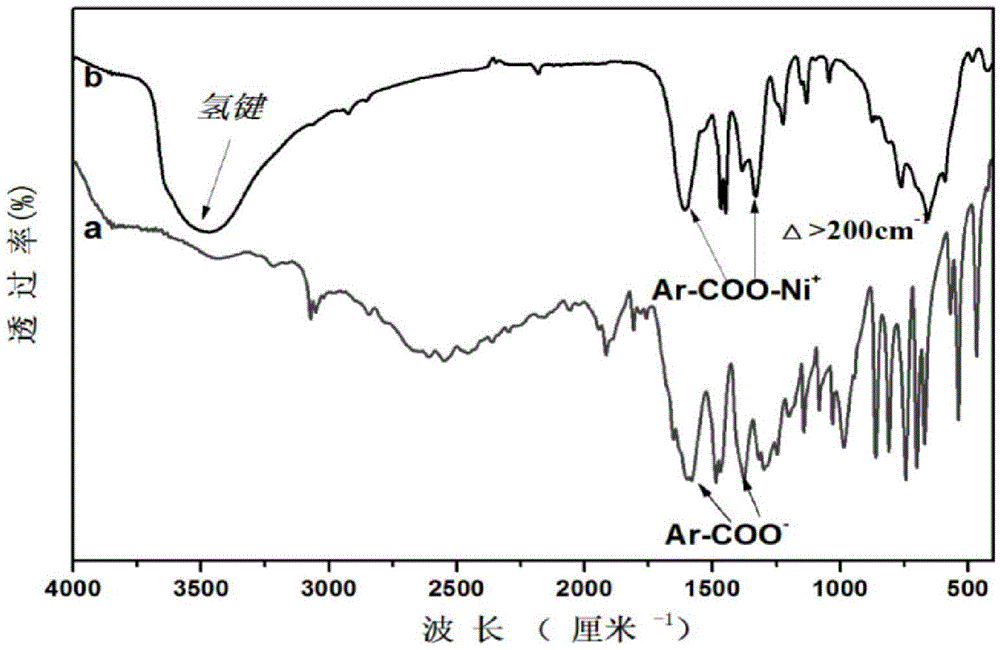

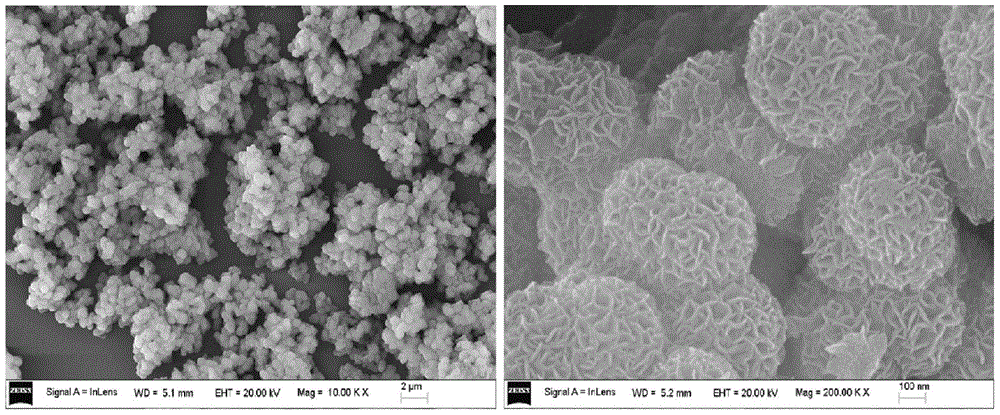

Nickel-titanium dioxide-carbon trinary nano composite catalyst and preparation method thereof

A titanium dioxide and nanocomposite technology, applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of active metal size, carbon layer structure is difficult to be effectively controlled, etc. problems, to achieve the effect of improving catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Weigh 5.816g Ni(NO 3 ) 2 ·6H 2 0 and 3.84g sodium salicylate are dissolved in 50mL deionized water respectively under room temperature and are mixed with salt solution, and two kinds of salt solutions prepared are poured in the four-necked flask, and begin to rotate at a constant speed, so that the salt solution is mixed; Measure 1mL of concentrated hydrochloric acid in a dry beaker (the mouth of the beaker is sealed with plastic film), draw 0.5mL of TiCl with a syringe 4 (CP>99%) and pour it into a dry beaker immediately. After the white smoke dissipates, open the film and stir with a glass rod for 5 minutes, then add deionized water (50mL) drop by drop until the yellow complex is completely dissolved in water and the solution is clear and transparent ; Finally, the configured TiCl 4 The solution is poured into a four-neck bottle;

[0029] 2) Weigh 14.42g of urea and dissolve it in 50mL of deionized water to prepare lye, and pour it directly into the stirring reac...

Embodiment 2

[0040] 1) Weigh 3.49g Ni(NO 3 ) 2 ·6H 2 0 and 2.56g sodium salicylate are dissolved in 50mL deionized water respectively at room temperature and are mixed with salt solution, and two kinds of salt solutions prepared are poured in the four-necked flask, and begin to rotate at a constant speed, so that the salt solution is mixed; Measure 1mL of concentrated hydrochloric acid in a dry beaker (the mouth of the beaker is sealed with plastic film), draw 0.5mL of TiCl with a syringe 4 (CP>99%) and pour it into a dry beaker immediately. After the white smoke dissipates, open the film and stir with a glass rod for 5 minutes, then add deionized water (50mL) drop by drop until the yellow complex is completely dissolved in water and the solution is clear and transparent ; Finally, the configured TiCl 4 The solution is poured into a four-neck bottle;

[0041] 2) Weigh 9.61g of urea and dissolve it in 50mL of deionized water to prepare lye, and pour it directly into the stirring reactio...

Embodiment 3

[0047] 1) Weigh 5.816g Ni(NO 3 ) 2 ·6H 2 0 and 3.84g sodium salicylate are dissolved in 50mL deionized water respectively under room temperature and are mixed with salt solution, and two kinds of salt solutions prepared are poured in the four-necked flask, and begin to rotate at a constant speed, so that the salt solution is mixed; Measure 1mL of concentrated hydrochloric acid in a dry beaker (the mouth of the beaker is sealed with plastic film), draw 0.5mL of TiCl with a syringe 4 (CP>99%) and pour it into a dry beaker immediately. After the white smoke dissipates, open the film and stir with a glass rod for 5 minutes, then add deionized water (50mL) drop by drop until the yellow complex is completely dissolved in water and the solution is clear and transparent ; Finally, the configured TiCl 4 The solution is poured into a four-neck bottle;

[0048] 2) Weigh 28.84g of urea and dissolve it in 50mL of deionized water to make lye, and pour it directly into the stirring react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com