Thermal insulation coating and its preparation method and application

A thermal insulation and coating technology, applied in the field of coatings, to achieve the effects of easy operation, reduced loss, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The thermal insulation coating of present embodiment 1 comprises A component and B component; Wherein,

[0037] Component A, by weight percentage, includes: 23% hollow glass microspheres, 7% rutile titanium dioxide, 3% expandable microsphere foaming agent, 1% organosilicon concentrated type defoamer (0.7% Aire900 defoamer and 0.3% Foamex N defoamer), 1% of inorganic anti-settling agent (0.3% ST modified hydrogenated pyrene sesame oil and 0.7% organic bentonite SD-2), 1% of leveling agent and 11% of DBE solvent and 53% high functionality epoxy resin.

[0038] Component B, by weight percentage, includes: 78% biuret and 22% butyl acetate.

[0039] The hollow glass microspheres described in Example 1 are 3M hollow glass microspheres from DuPont Company.

[0040] The titanium dioxide is rutile titanium dioxide from DuPont Company.

[0041] The expandable microsphere foaming agent adopts the expandable microsphere foaming agent produced by DuPont Company.

[0042] The sil...

Embodiment 2

[0053] The thermal insulation coating of present embodiment 2 comprises A component and B component; Wherein,

[0054] Component A, by weight percentage, includes: 23% hollow glass microspheres, 7% rutile titanium dioxide, 1% expandable microsphere foaming agent, 1% silicone concentrated defoamer (0.3% Aire900 defoamer and 0.7% Foamex N defoamer), 1% inorganic anti-settling agent (0.3% ST modified hydrogenated pyrene sesame oil and 0.7% organic bentonite SD-2), 1% leveling agent and 11% DBE solvent and 55% high functionality epoxy resin.

[0055] Component B, by weight percentage, includes: 85% biuret and 15% butyl acetate.

[0056] Above-mentioned each raw material all adopts the product that each manufacturer that records in embodiment 1 provides. But not limited thereto, materials with the same or similar functional effects that can be obtained by those skilled in the art can be used in the present invention.

[0057] The preparation method of the thermal insulation coat...

Embodiment 3

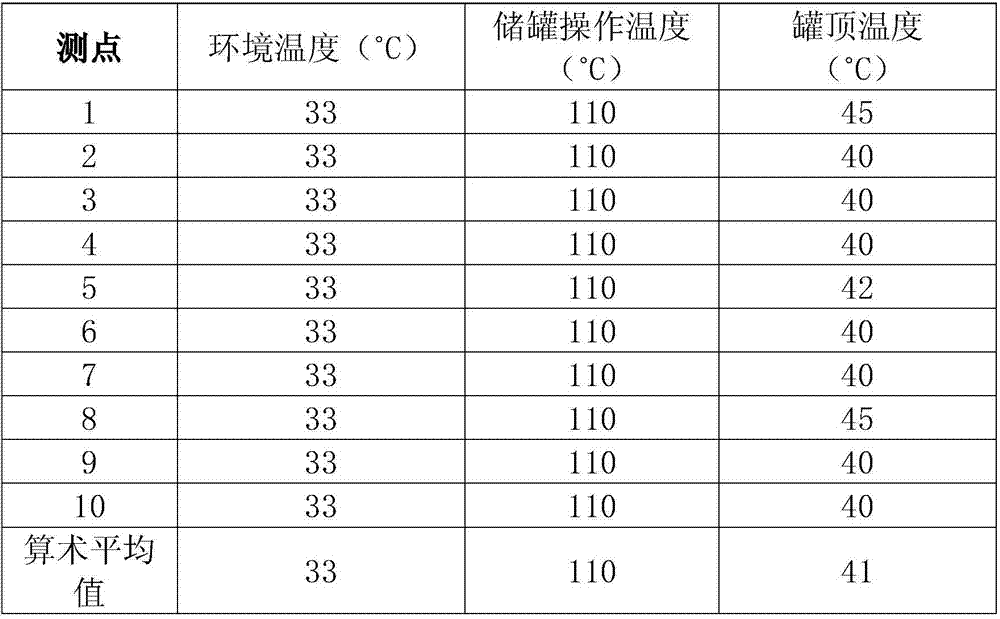

[0059] Application of thermal insulation coating sprayed on the outer surface of high temperature equipment as thermal insulation coating

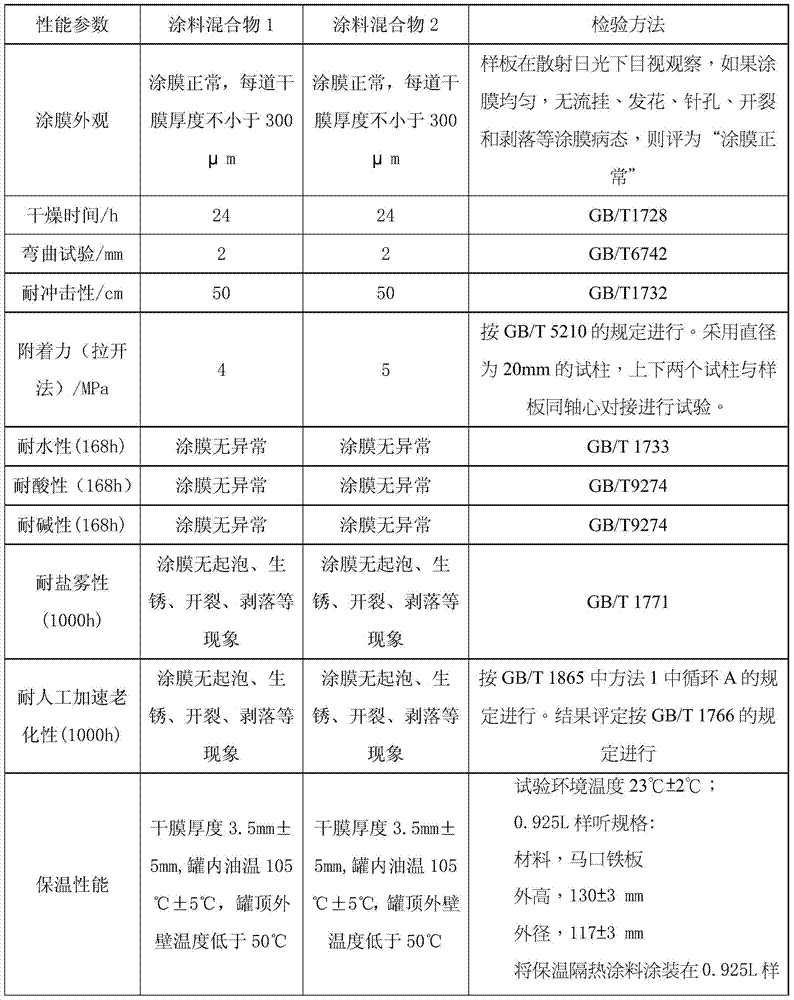

[0060] Mix component A and component B in the thermal insulation coating in Example 1 and Example 2 according to the mass ratio of 3-6:1 to obtain a coating mixture, and then spray the coating mixture outside the high-temperature equipment The surface is cured at room temperature to obtain a thermal insulation coating.

[0061] Preferably, the coating mixture is obtained after mixing component A and component B according to a mass ratio of 4-5.5:1. More preferably, the coating mixture is obtained after mixing component A and component B according to the mass ratio of 4.5-5:1.

[0062] The thermal insulation coating has a thickness of 2-8 mm to achieve a good thermal insulation effect. After comprehensive consideration of the coating thickness and heat insulation effect, the thickness of the thermal insulation coating is preferably 3-5mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com