A method for improving the biofinishing effect of cellulase on sulfur dyed fabrics

A technology of cellulase and biological finishing, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc. It can solve the problems of low hairiness removal rate on the surface of fabrics and large amount of cellulase, and achieve the goal of simple method and avoiding waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

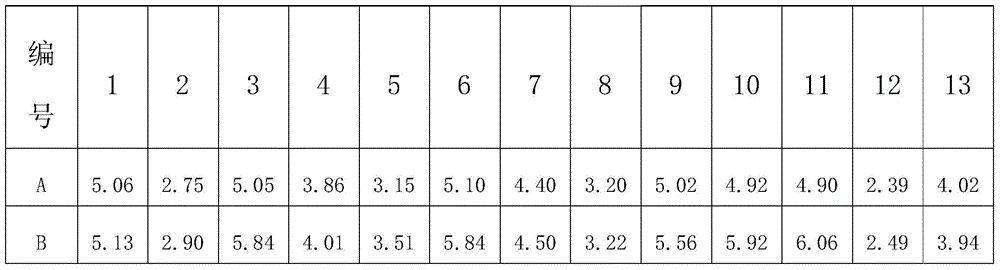

[0035] According to the central compound experiment plan listed in Table 1, according to the test method of cellulose filter paper enzyme activity, test the absorbance of the cellulase L4 test solution under various conditions, so as to calculate the enzyme activity of cellulase. Use Minitab software to analyze the filter paper enzyme L4 activity of the cellulase in Table 2, and obtain the equivalent curve of the enzyme activity, and further analyze the highest activity value and activity greater than 5×10 6 Temperature and pH range at U / g

[0036] The center composite experiment design scheme in the embodiment 1 of table 1

[0037] serial number 1 2 3 4 5 6 7 8 9 10 11 12 13 temperature / ℃ 60 40 50 50 60 50 50 40 50 50 50 40 60 pH 5.5 4.5 5.0 5.5 4.5 5.0 4.5 5.0 5.0 5.0 5.0 5.5 5.0

[0038] In table 2 embodiment 1, cellulase activity compares (10 6 U / g)

[0039]

[0040] A is cellulase solution without sodium...

Embodiment 2

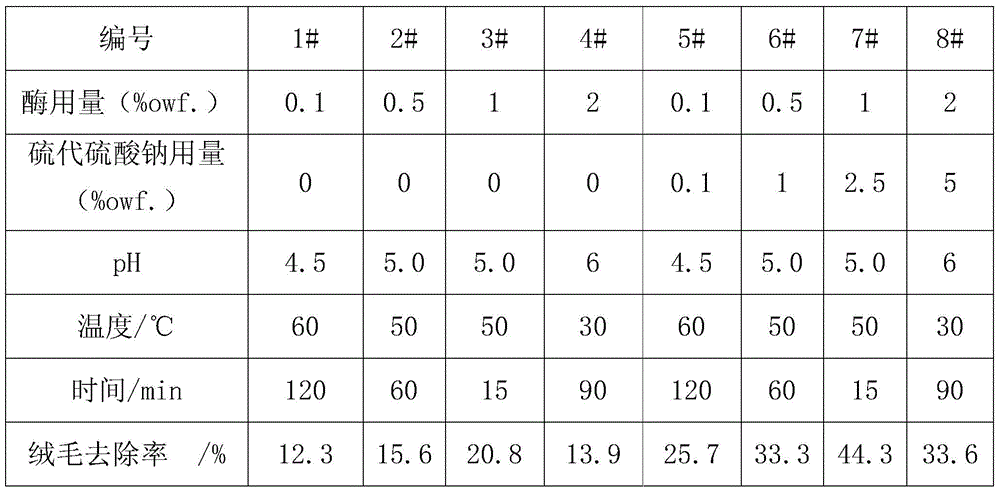

[0047] Add 150mL of distilled water into the dyeing cup, add the required sodium thiosulfate according to the dosage and process parameters listed in Table 5, and set the weight to 400g. Add 20g of knitted weft-knitted fabric dyed with sulfur black, treat it at room temperature for 5 minutes, then add the required cellulase L4, adjust the pH value with acetic acid and sodium acetate solution, raise the temperature to the required temperature, and continue the treatment for a certain period of time. After finishing, take out the cloth sample, wash it once with clean water, and test the hairiness removal rate of the fabric after drying.

[0048] Process conditions and biological treatment effect (fluff removal rate %) of table 5 fabric treatment

[0049]

[0050] As can be seen from Table 5, under the same experimental conditions, the same method was used to carry out cellulase biopolishing treatment on vulcanized dyed fabrics, adding sodium thiosulfate pretreated dyed fabric...

Embodiment 3

[0054] Add 150mL of distilled water into the dyeing cup, add the required amount of sodium thiosulfate according to the dosage and process parameters listed in Table 6, and set the weight to 400g. Add 20g of knitted weft-knitted fabric dyed with sulfur black, treat it at room temperature for 3 minutes, then add the required amount of cellulase L1, L2, L3, adjust to the required pH value, raise the temperature to the required temperature, and continue the treatment After a certain period of time, take out the cloth sample, wash it with clean water for 3 times, and test the hairiness removal rate of the fabric after drying.

[0055] Process conditions and biological treatment effect (fluff removal rate %) of table 6 fabric treatment

[0056]

[0057] L1, L2, L3 are three different types of cellulase, among which L3 is neutral cellulase. It can be seen from Table 6 that the use of sodium thiosulfate pretreatment can significantly improve the fluff removal rate of the fabric, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com