Processing method of cold fresh sorghum noodles

A processing method and cold fresh noodle technology, applied in the processing field of sorghum cold fresh noodles, can solve the problems of restricting the comprehensive utilization of sorghum, sodium hydroxide residue, poor taste and quality, etc., and achieve high nutritional value and health care effect, single Low Ning content, easy to digest and absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

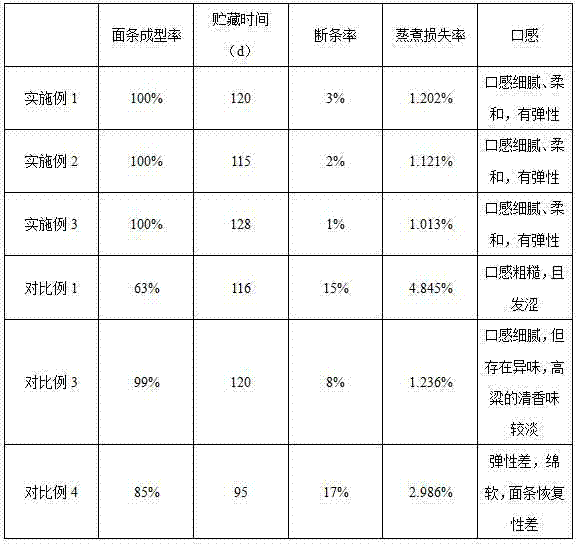

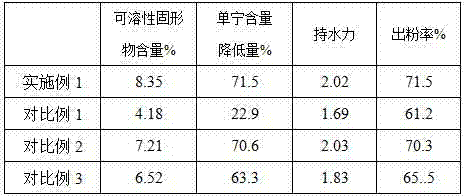

Examples

Embodiment 1

[0031] A processing method for sorghum cold fresh noodles. The sorghum cold fresh noodles are made of the following raw materials in parts by weight: 15 parts of germinated sorghum whole flour, 70 parts of wheat flour, 0.5 part of konjac flour, and 2 parts of table salt, specifically comprising the following steps:

[0032] (1) Sorghum pretreatment: After selecting, sieving, removing impurities, and cleaning the sorghum in parts by weight, add 1.5 mg / L ozone water (the ozone water should not pass through the sorghum), and then add 2% of sorghum weight Calcium acetate, soak for 2 minutes, filter and wash, put the washed sorghum into a container containing soybean soymilk (soybean soymilk should not pass through sorghum), add PVP accounting for 1% of sorghum weight, soak at room temperature for 24 hours, after soaking, sorghum Take it out and place it in an incubator with a humidity of 80% and a temperature of 30°C until the sorghum buds are over 2mm long, then clean the germinat...

Embodiment 2

[0038] A processing method for sorghum cold fresh noodles, the sorghum cold fresh noodles are made of the following raw materials in parts by weight: 10 parts of germinated sorghum whole flour, 80 parts of wheat flour, 0.4 part of konjac flour, and 1 part of table salt, specifically comprising the following steps:

[0039] (1) The preparation method of coarse germinated sorghum powder is the same as in Example 1;

[0040](2) Extruded superfine grinding: add the whole germinated sorghum flour to 20% of its weight in water, and then feed it into a twin-screw extruder for extruding and extruding at a feeding speed of 300g / min. The screw speed of 300r / min is used for four-stage segmental extrusion, and the segmental extrusion temperatures are 65°C, 95°C, 115°C, and 150°C respectively to obtain extruded materials, which are ultrafinely pulverized to 400 meshes. Whole germinated sorghum flour;

[0041] (3) Add water accounting for 37% of the total weight of the konjac flour and tab...

Embodiment 3

[0045] A processing method for sorghum cold fresh noodles. The sorghum cold fresh noodles are made of the following raw materials in parts by weight: 20 parts of germinated sorghum whole flour, 70 parts of wheat flour, 0.8 parts of konjac flour, and 4 parts of table salt, specifically comprising the following steps:

[0046] (1) The preparation method of coarse germinated sorghum powder is the same as in Example 1;

[0047] (2) Extruded superfine pulverization: adding 30% water to the coarse germinated sorghum powder, and then feeding it into a twin-screw extruder for extruding and extruding at a feeding speed of 300g / min. The screw speed of 300r / min is used for four-stage segmental extrusion, and the segmental extrusion temperatures are 70°C, 100°C, 120°C, and 170°C respectively to obtain extruded materials, which are ultrafinely pulverized to 600 meshes. Whole germinated sorghum flour;

[0048] (3) Add water accounting for 35% of the total weight of the konjac flour and sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com