A kind of preparation method of liquid nisin preservative

A preservative and liquid technology, applied in the field of bioengineering, can solve the problems of low extraction yield, insufficient market competitiveness, and high cost, and achieve the effects of easy mixing, outstanding antiseptic effect, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

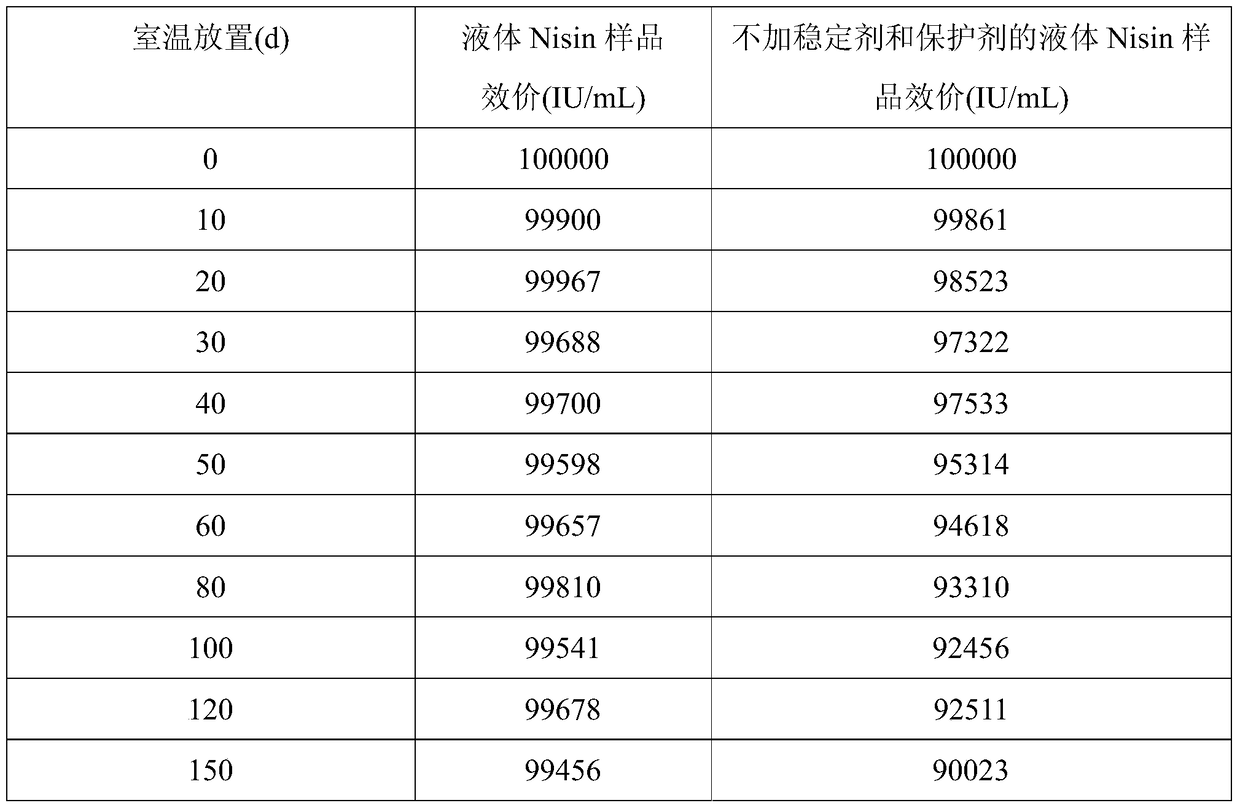

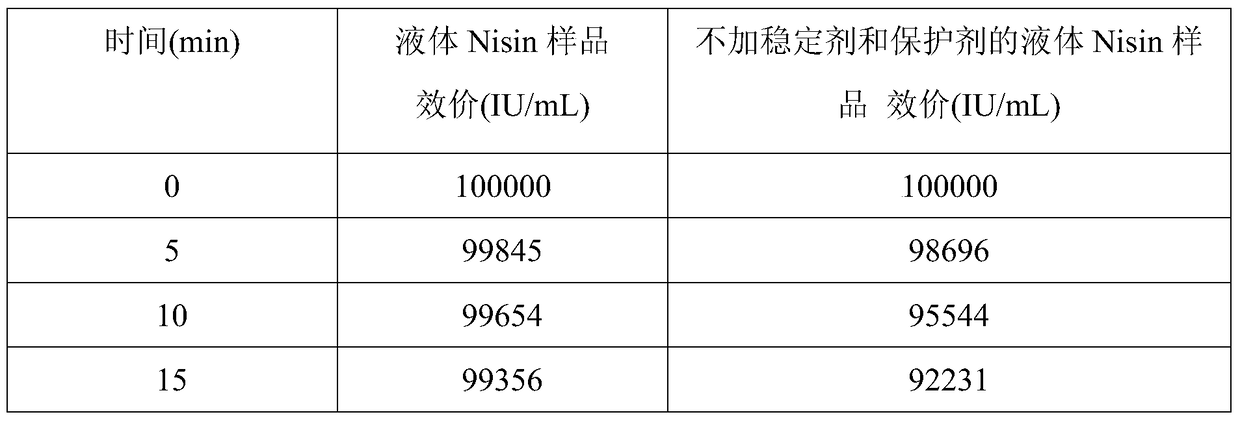

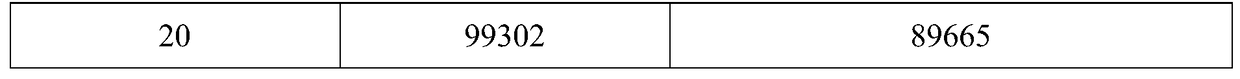

Examples

Embodiment 1

[0026] (1) Fermentation broth pretreatment, ceramic membrane membrane filtration to remove impurities such as bacteria and macromolecular proteins, to obtain the fermented liquid of Nisin.

[0027] (2) Foam separation and concentration, feed air into the foam separation device, control the air flow rate to 3-6L / h, and collect the foam liquid.

[0028] (3) Foam defoaming treatment, utilizing the principle of physical defoaming, combined with adding polyoxyethylene polypropylene glyceryl ether for defoaming treatment, to obtain a high-titer Nisin solution (100000IU / mL).

[0029] (4) Adding protective agent, start stirring, add 2% sodium chloride, 0.5% sucrose, 0.3% sodium glutamate, 0.6% maltodextrin respectively, and stir evenly to dissolve various protective agents completely. The amount of addition is based on the weight of the high titer Nisin solution in step (3).

[0030] (5) Adding stabilizers, start stirring, add 0.8% sorbitol, 0.4% microcrystalline cellulose, 0.0003% ...

Embodiment 2

[0032] (1) Fermentation broth pretreatment, ceramic membrane membrane filtration to remove impurities such as bacteria and macromolecular proteins, to obtain the fermented liquid of Nisin.

[0033] (2) Foam separation and concentration, pass carbon dioxide and air into the foam separation device, the ratio is 0.1:1, control the air flow rate to 5-8L / h, and collect the foam liquid.

[0034] (3) Foam defoaming treatment, using the principle of physical defoaming, combined with adding edible oil for defoaming treatment, to obtain a high titer Nisin solution (100000IU / mL).

[0035] (4) Addition of protective agent, start stirring, add 1.8% sodium chloride, 0.6% sucrose, 0.2% sodium glutamate, 0.4% maltodextrin respectively, and stir evenly to dissolve various protective agents completely. The amount of addition is based on the weight of the high titer Nisin solution in step (3).

[0036](5) Adding stabilizer, start stirring, add 0.05% sorbitol, 0.02% microcrystalline cellulose, ...

Embodiment 3

[0038] (1) Fermentation broth pretreatment, ceramic membrane membrane filtration to remove impurities such as bacteria and macromolecular proteins, to obtain the fermented liquid of Nisin.

[0039] (2) Foam separation and concentration, pass carbon dioxide, air and nitrogen into the foam separation device, the ratio is 0.1:1:0.05, control the flow rate to 8-10L / h, and collect the foam liquid.

[0040] (3) Foam defoaming treatment, using the principle of physical defoaming, combined with adding edible oil for defoaming treatment, to obtain a high-potency Nisin solution with a potency of 100,000 IU / mL.

[0041] (4) Adding protective agent, start stirring, add 2% sodium chloride, 0.8% sucrose, 0.1% sodium glutamate, 0.5% maltodextrin respectively, and stir evenly to dissolve various protective agents completely. The amount of addition is based on the weight of the high titer Nisin solution in step (3).

[0042] (5) Adding stabilizer, start stirring, add 0.03% sorbitol, 0.015% m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com