Environmentally friendly over-stable polyphase foam system and preparation method thereof

A foam system and stable technology, applied in the field of environment-friendly ultra-stable multi-phase foam system and its preparation, can solve the problems of poor environmental friendliness and degradability, electrochemical corrosion of pipelines and equipment, and low utilization efficiency of nanoparticles. To achieve the effect of effective utilization, good ecological security, good ecological security and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 0.25g alkyl glycoside, 0.003g C to 100mL deionized water 12 -3-C 12 2Br, 1.5g of hydrophilic silica nanoparticles, stirred with a high-speed mixer at 8000rpm for 3 minutes, and quickly transferred to a graduated 500mL measuring cylinder to produce about 430mL of foam with a drainage half-life of about 5000s.

Embodiment 2

[0023] The heterogeneous foam system is 100mL deionized water containing 0.1g surfactant alkyl glycoside APG, 0.020g cationic gemini surfactant C 12 -3-C 12 2Br and 1.2g of silica nanoparticles were stirred with a high-speed mixer at 8000rpm for 3 minutes, and quickly transferred to a graduated 500mL graduated cylinder to produce about 430mL of foam with a drainage half-life of about 5000s.

Embodiment 3

[0025] The heterogeneous foam system is 100mL deionized water containing 0.5g surfactant alkyl glycoside APG, 0.001g cationic gemini surfactant C 12 -3-C 12 2Br and 1g of silica nanoparticles were stirred with a high-speed stirrer at 8000rpm for 3 minutes, and quickly transferred to a graduated 500mL graduated cylinder to produce about 430mL of foam with a drainage half-life of about 5000s.

[0026] In order to further illustrate the stability of the multiphase foam system of the present invention, the present invention has done a large number of comparative experiments to illustrate the stability of the multiphase foam system of the present invention.

[0027] Take the heterogeneous foam system prepared in Example 1 as an example.

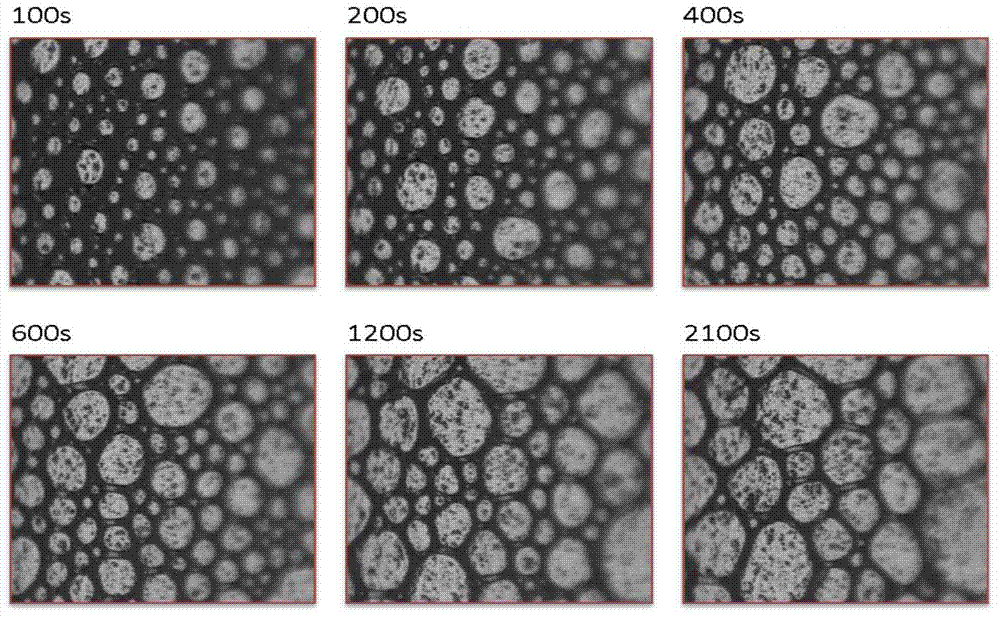

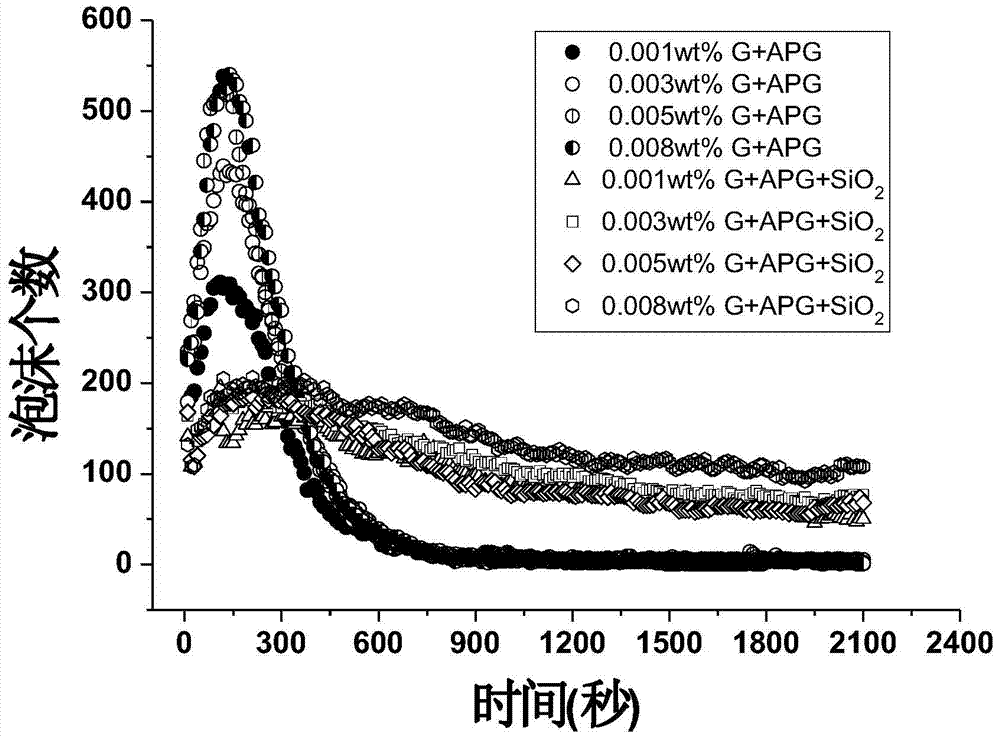

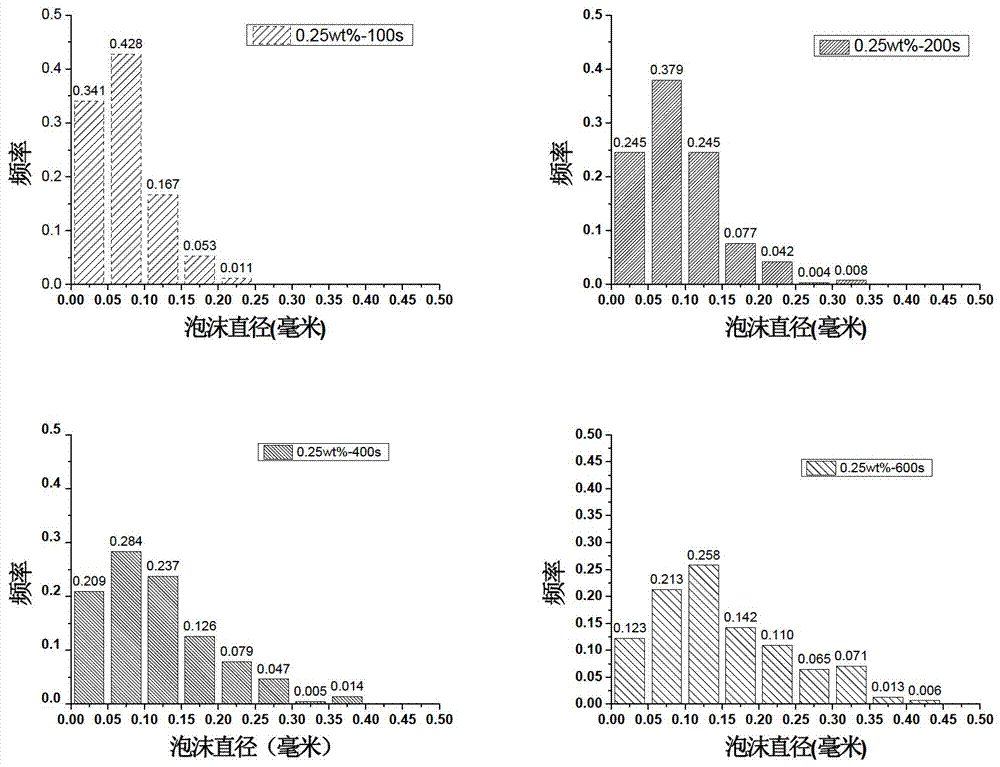

[0028] Use a foam scanner to study the change of foam shape, number, liquid content in foam, etc. over time, 0.003wt%C 12 -3-C 12 2Br+0.25wt%APG+1.5wt%SiO 2 , 25°C, nitrogen flow rate 400mL / min (eg figure 1 shown)

[0029] from figure 1 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com