Preparation method of metal-based super-hydrophobic surface

A hydrophobic surface and metal-based technology, which is applied to the device for coating liquid on the surface, special surface, coating, etc., can solve the problems of special processing equipment, harsh preparation conditions, and complicated process, and achieve simple and easy preparation process , low production cost, safe and reliable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

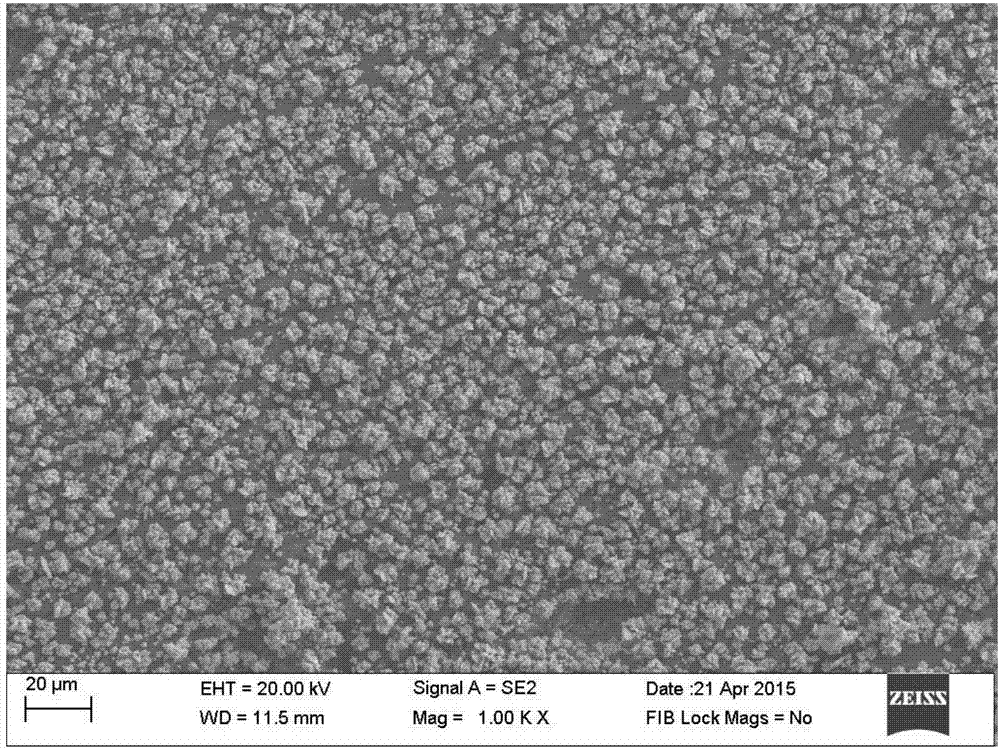

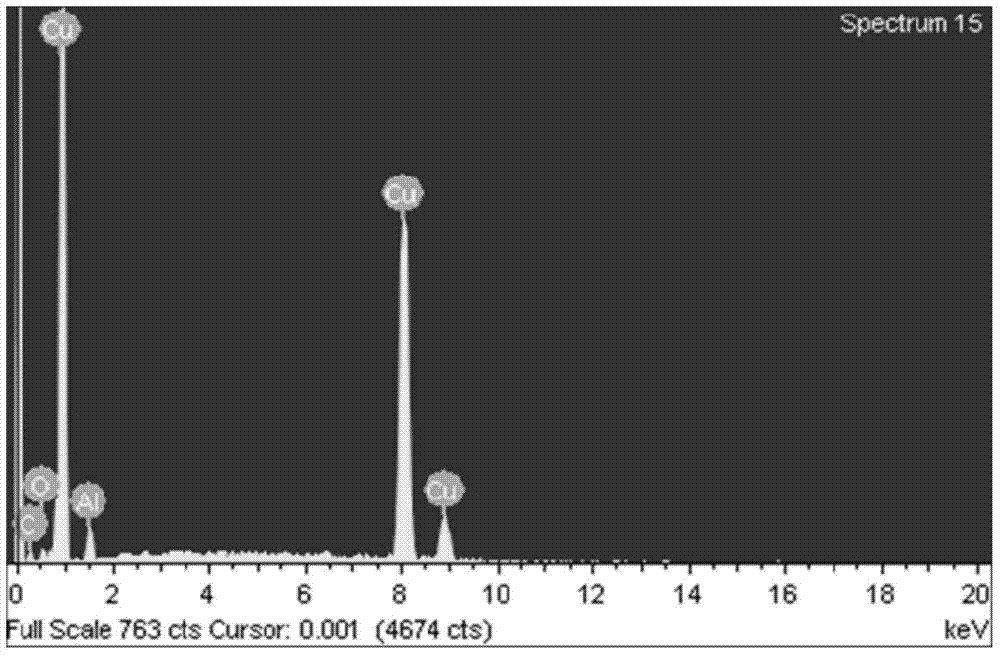

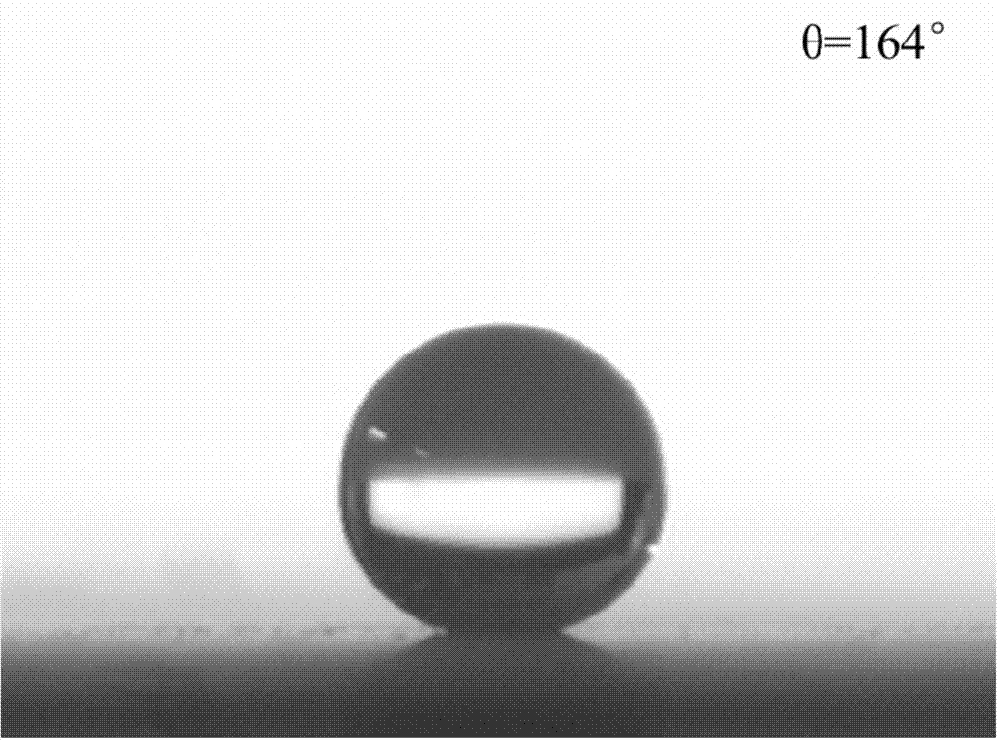

[0045] Embodiment 1, preparation aluminum-based superhydrophobic surface

[0046] Prepare the aluminum-based superhydrophobic surface according to the following steps:

[0047] (1) Use metallographic sandpaper with a particle size of 500 mesh to grind the aluminum sheet evenly and meticulously. After the grinding is completed, immerse the aluminum sheet in anhydrous ethanol and deionized water for 5 minutes for ultrasonic cleaning to remove impurities and oil on the surface;

[0048] (2) Immerse the aluminum sheet treated in step (1) into the prepared mixed solution A of 0.05mol / L hydrochloric acid and 0.1mol / L copper nitrate for etching and replacement reaction. After immersion for 10 minutes, the surface Take it out and rinse the surface with deionized water to wash away soluble salts and shallower solid reactants;

[0049] (3) Immerse the aluminum sheet treated in step (2) into the prepared 1wt% fluorosilane solution (F-1060) for modification for 30 minutes;

[0050] (4) ...

Embodiment 2

[0053] Embodiment 2, prepare copper-based superhydrophobic surface

[0054] (1) Use metallographic sandpaper with a particle size of 500 mesh to uniformly and meticulously polish the copper sheet. After the polishing is completed, immerse the copper sheet in anhydrous ethanol and deionized water for 5 minutes for ultrasonic cleaning to remove surface impurities and oil stains;

[0055] (2) Immerse the copper sheet treated in step (1) into the prepared mixed solution B of 4.0mol / L nitric acid and 0.02mol / L silver nitrate for etching and replacement reaction. After immersion for 10min, take out the surface , and rinse the surface with deionized water to wash off soluble salts and shallower solid reactants;

[0056] (3) Immerse the copper sheet treated in step (2) into the prepared 1wt% fluorosilane solution (F-1060) for modification for 30 minutes;

[0057] (4) Put the copper sheet modified in step (3) into an oven, dry at 100°C for 30 minutes, and cool to room temperature afte...

Embodiment 3

[0060] Embodiment 3, preparation aluminum-based superhydrophobic surface

[0061] Prepare the aluminum-based superhydrophobic surface according to the following steps:

[0062] (1) Use metallographic sandpaper with a particle size of 1000 mesh to uniformly and meticulously polish the aluminum sheet. After the grinding is completed, immerse the aluminum sheet in anhydrous ethanol and deionized water for 5 minutes for ultrasonic cleaning to remove impurities and oil stains on the surface;

[0063] (2) Immerse the aluminum sheet treated in step (1) into the prepared mixed solution A of 0.1mol / L hydrochloric acid and 0.1mol / L copper nitrate for etching and replacement reaction. After immersion for 5 minutes, take out the surface , and rinse the surface with deionized water to wash off soluble salts and shallower solid reactants;

[0064] (3) Immerse the aluminum sheet treated in step (2) into the prepared 1wt% fluorosilane solution (F-1060) for modification for 30 minutes;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com