Method used for growth of transition metal chalcogenide crystals via metal fluxing agent method

A technology of chalcogen compound and flux method, which is applied in chemical instruments and methods, melt from molten solvent, single crystal growth, etc., can solve the problem of difficult to obtain high-quality and large-sized crystals, and achieve high chemical stability Sex and heat stability, good quality, short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Growth of transition metal chalcogenide MoS by a metal flux method 2 A method for crystallization comprising the steps of:

[0038] (1) The raw materials elemental Mo, elemental S, and elemental Sn are mixed according to the molar ratio of 1:2:10, mixed evenly, put into a clean high-purity quartz tube, and vacuumed by a vacuum pump to make the inside of the quartz tube reach 1×10 -3 Pa, and then sinter and seal the quartz tube with an oxyhydrogen flame; put the quartz tube into a well-type furnace, raise the temperature to 1150°C, and keep it warm for 20h;

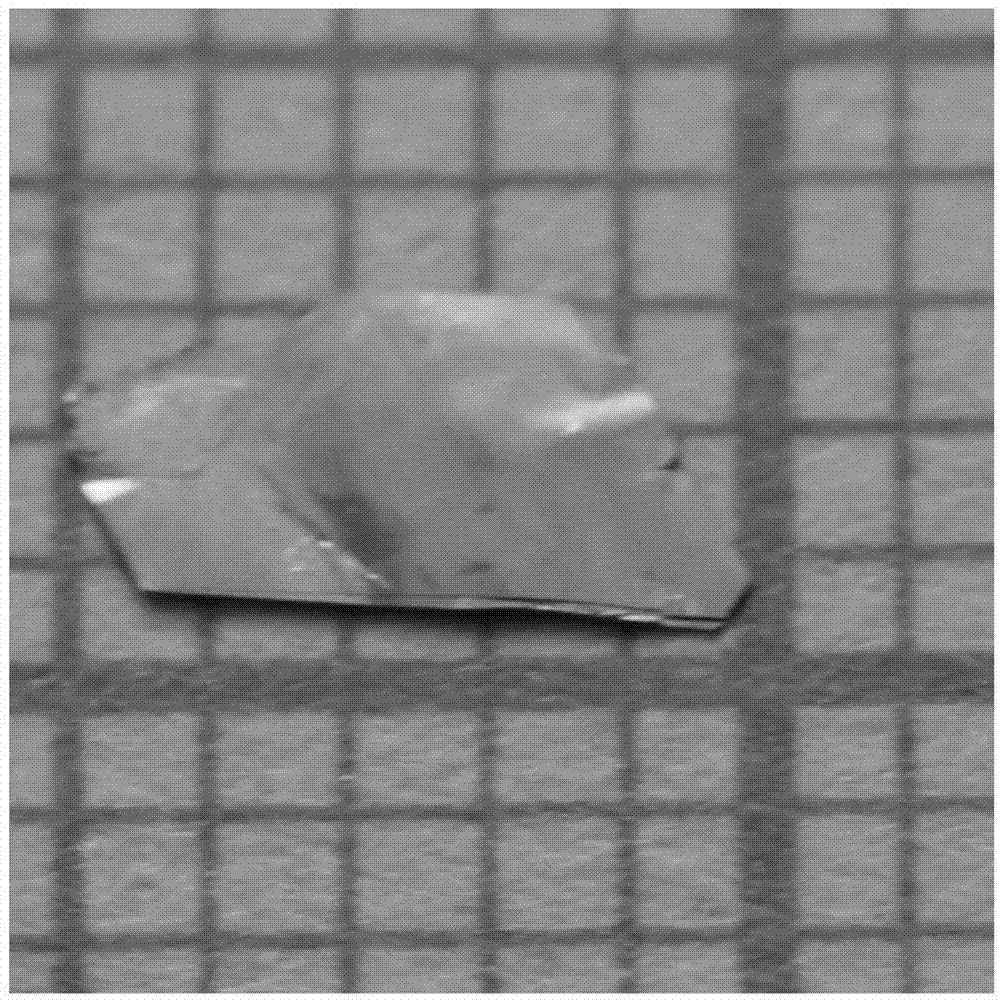

[0039] (2) Cool down at a rate of 6°C / h for the first stage of cooling, so that the crystals spontaneously crystallize. When the temperature drops to 900°C, after holding at 900°C for 20 hours, quickly take out the quartz tube from the pit furnace, and then centrifugally quench , let it cool down to room temperature within 10 minutes, and then get silver-gray 0.5mm×1mm MoS 2 crystals.

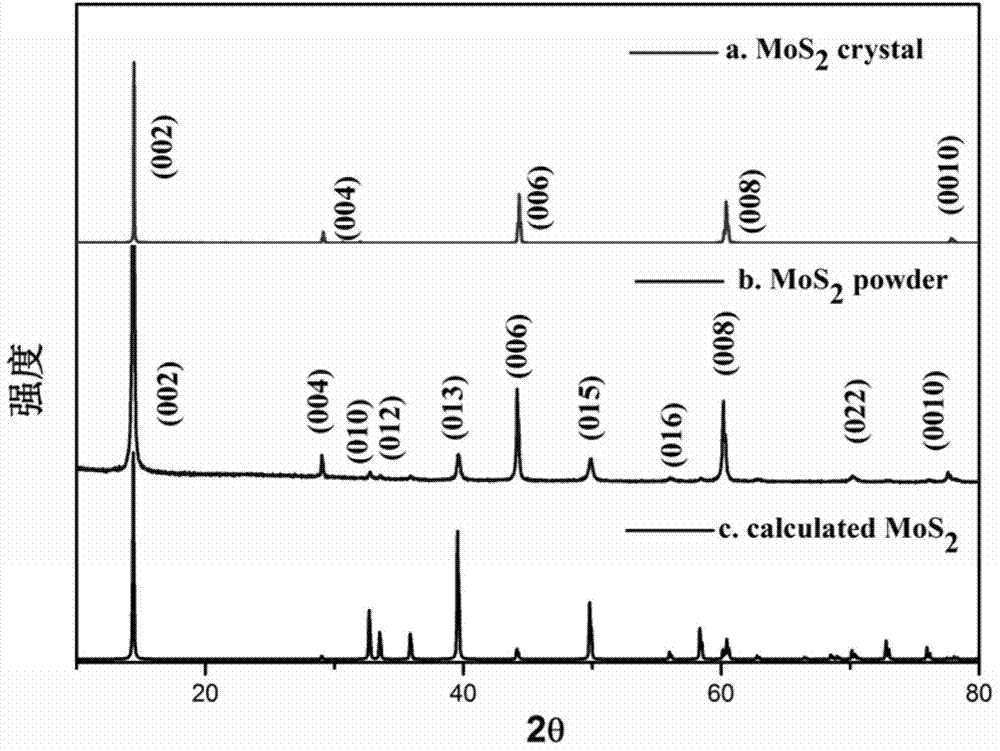

[0040] Test the MoS obtain...

Embodiment 2

[0042] Growth of transition metal chalcogenide MoS by a metal flux method 2 A method for crystallization comprising the steps of:

[0043] (1) The raw materials elemental Mo, elemental S, and elemental Sn are mixed according to the molar ratio of 1:2:10, mixed evenly, put into a clean high-purity quartz tube, and vacuumed by a vacuum pump to make the inside of the quartz tube reach 1×10 -3Pa, and then sinter and seal the quartz tube with an oxyhydrogen flame; put the quartz tube into a well-type furnace, raise the temperature to 1150°C, and keep it warm for 20h;

[0044] (2) Cool down at a rate of 2°C / h for the first stage of cooling, so that the crystals crystallize spontaneously. When the temperature drops to 900°C, after holding at 900°C for 20 hours, quickly take out the quartz tube from the pit furnace, and then centrifugally quench it. Allow it to cool down to room temperature in 10 minutes to obtain silver-gray 3mm×4mm flake MoS 2 Crystal, the crystal quality is the b...

Embodiment 3

[0051] Growth of transition metal chalcogenide MoS by a metal flux method 2 A method for crystallization comprising the steps of:

[0052] (1) The raw materials elemental Mo, elemental S, and elemental Sn are mixed according to the molar ratio of 1:2:5, mixed evenly, put into a clean high-purity quartz tube, and vacuumed by a vacuum pump to make the inside of the quartz tube reach 1×10 -3 Pa, then sinter and seal the quartz tube with an oxyhydrogen flame; put the quartz tube into a well-type furnace, raise the temperature to 1100°C, and keep it warm for 20h;

[0053] (2) Cool down at a rate of 6°C / h for the first stage of cooling, so that the crystals crystallize spontaneously. When the temperature drops to 900°C, after holding at 900°C for 20 hours, quickly take out the quartz tube from the pit furnace, and then centrifugally quench it. Allow it to cool down to room temperature in 5 minutes to obtain silver-gray millimeter-scale flake MoS 2 crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com