A reduced graphene oxide/iron tetroxide/cdsete@zns@sio 2 Preparation method of nanocomposite

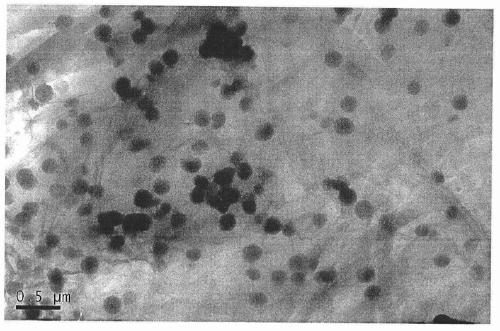

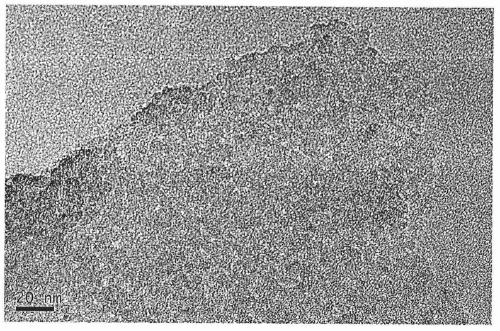

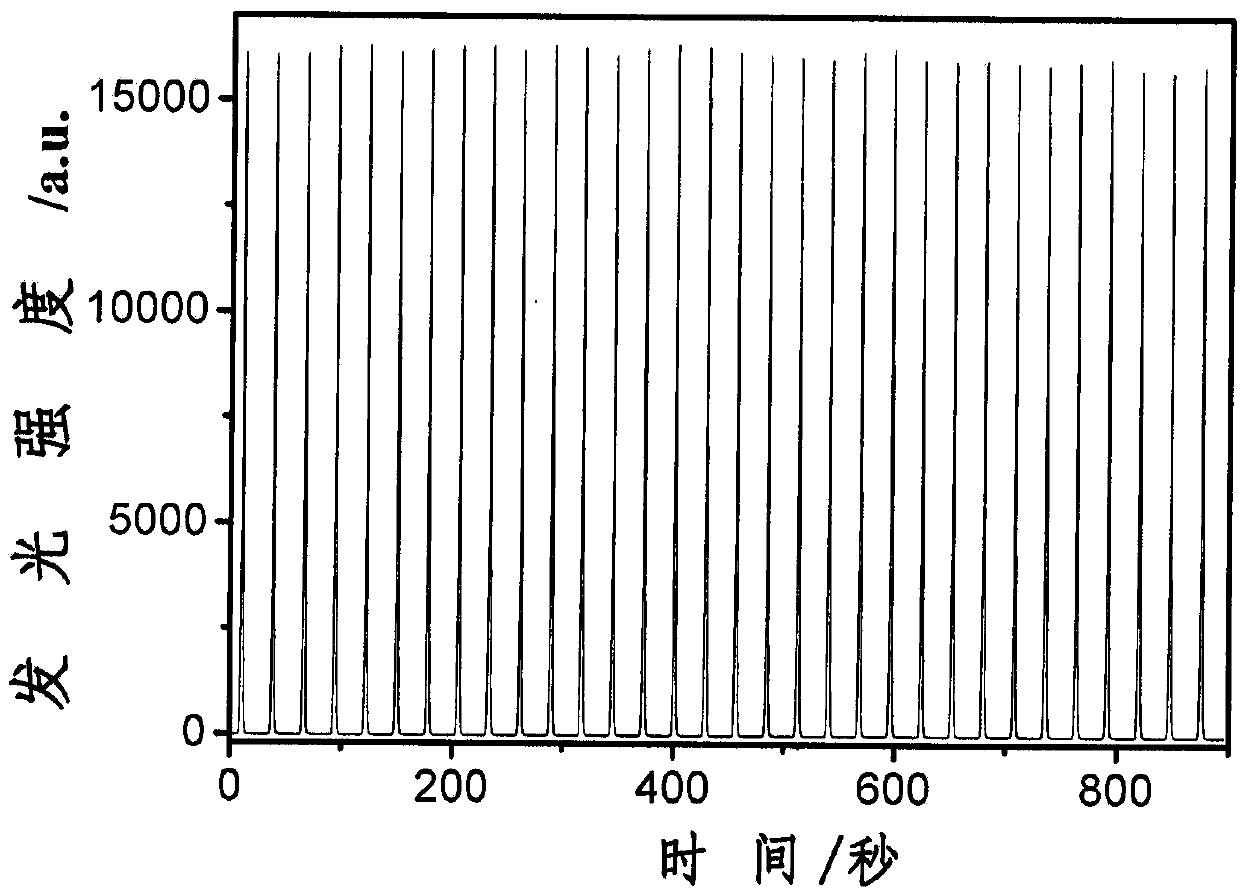

A technology of iron ferric oxide and nanocomposites, applied in the direction of iron oxide/iron hydroxide, graphene, chemical instruments and methods, etc., to achieve the effects of simple preparation method, high electrochemiluminescence intensity, and uniform particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 105 mg of graphene oxide into 35 mL of ethylene glycol and sonicate for 30 min to obtain a uniformly dispersed graphene oxide suspension.

[0022] (2) Add 0.75 g of ferric chloride to the mixed solution obtained in the first step, and stir for 20 minutes to dissolve it.

[0023] (3) Add 1.80 g of sodium acetate to the mixed solution obtained in the second step, and stir for 60 minutes to dissolve it.

[0024] (4) Pour the above mixture into a polytetrafluoroethylene reactor, conduct a hydrothermal reaction at 180°C for 12 hours, wash with deionized water and ethanol three times each, and dry in vacuum at 60°C to obtain a reduced graphene oxide / ferric oxide nanocomposite things.

[0025] (5) The obtained reduced graphene oxide / ferric oxide nanocomposite is dispersed in 0.2% polydiallyl dimethyl ammonium chloride solution, ultrasonic 30min, obtains black solution, then washes three times with deionized water, The reduced graphene oxide / ferric oxide nanocomposite...

Embodiment 2

[0029] (1) Add 90 mg of graphene oxide into 35 mL of ethylene glycol and sonicate for 60 min to obtain a uniformly dispersed graphene oxide suspension.

[0030] (2) Add 0.80 g of ferric chloride to the mixed solution obtained in the first step, and stir for 30 minutes to dissolve it.

[0031] (3) Add 1.50 g of sodium acetate to the mixed solution obtained in the second step, and stir for 60 minutes to dissolve it.

[0032] (4) Pour the above mixture into a polytetrafluoroethylene reactor, conduct a hydrothermal reaction at 160°C for 24 hours, wash with deionized water and ethanol three times each, and dry in vacuum at 60°C to obtain a reduced graphene oxide / ferric oxide nanocomposite things.

[0033] (5) The obtained reduced graphene oxide / ferric oxide nanocomposite is dispersed in 0.1% polydiallyl dimethyl ammonium chloride solution, ultrasonic 60min, obtains black solution, then washes three times with deionized water, The reduced graphene oxide / ferric oxide nanocomposite ...

Embodiment 3

[0036] (1) Add 150 mg of graphene oxide into 35 mL of ethylene glycol and sonicate for 15 min to obtain a uniformly dispersed graphene oxide suspension.

[0037] (2) Add 0.75 g of ferric chloride to the mixed solution obtained in the first step, and stir for 20 minutes to dissolve it.

[0038] (3) Add 1.80 g of sodium acetate to the mixed solution obtained in the second step, and stir for 30 minutes to dissolve it.

[0039] (4) Pour the above mixture into a polytetrafluoroethylene reactor, conduct a hydrothermal reaction at 180°C for 12 hours, wash with deionized water and ethanol three times each, and dry in vacuum at 60°C to obtain a reduced graphene oxide / ferric oxide nanocomposite things.

[0040] (5) The obtained reduced graphene oxide / ferric oxide nanocomposite is dispersed in 0.1% polydiallyl dimethyl ammonium chloride solution, ultrasonic 60min, obtains black solution, then washes three times with deionized water, The reduced graphene oxide / ferric oxide nanocomposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com