Adhesive agent for injection molding of aluminum nitride ceramic and application method of adhesive agent

A technology of aluminum nitride ceramics and injection molding, which is applied in the field of binders for aluminum nitride ceramics injection molding, can solve the problems of high cost, difficult to prepare, small size, complex shape, etc., and achieve good toughness, high strength, and reduce defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

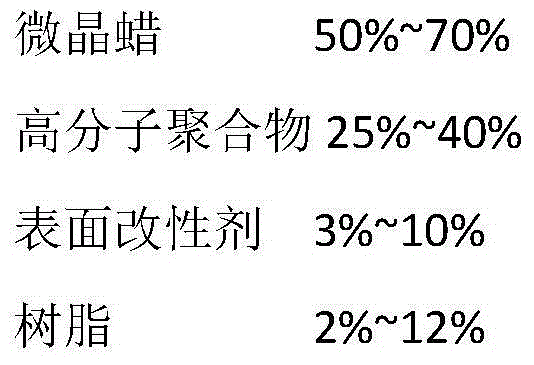

[0021] A binder for injection molding of aluminum nitride ceramics of the present invention, the binder composition is as follows:

[0022]

[0023] The specific process steps of the binder for injection molding of aluminum nitride ceramics and the injection molding process of aluminum nitride of this embodiment are as follows:

[0024] (1) Feed material preparation: first, 1000 g of aluminum nitride powder (oxygen content 0.65%) and 30 g of sintering aid yttrium oxide were ball milled and mixed in alcohol, and then dried to obtain a mixed powder. Put it, 192g of binder and mixed powder of the above ingredients into a kneader for kneading, the kneading temperature is 170°C, and the rotation speed is 30r / min. After the mixture is in a molten state, continue kneading for 1h, and take it out after cooling. feeding.

[0025] (2) Injection molding: After crushing the feed material, it is formed by an injection molding machine at an injection temperature of 160° C. to obtain an ...

Embodiment 2

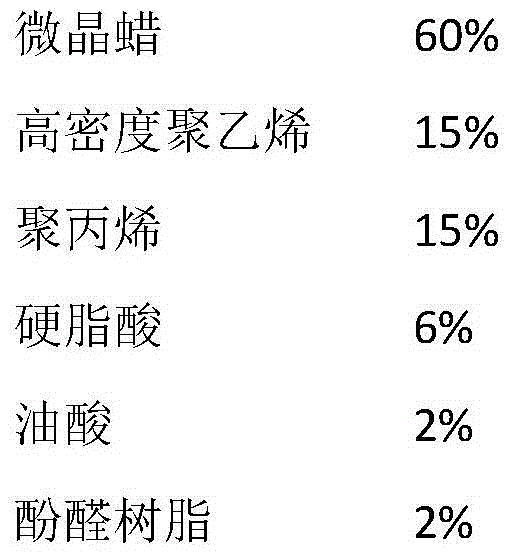

[0031] A binder for injection molding of aluminum nitride ceramics of the present invention, the binder composition is as follows:

[0032]

[0033] The specific process steps of the binder for injection molding of aluminum nitride ceramics and the injection molding process of aluminum nitride of this embodiment are as follows:

[0034] (1) Feed material preparation: first, 1000 g of aluminum nitride powder (with an oxygen content of 0.65%) and 30 g of sintering aid yttrium oxide were ball milled and mixed in alcohol, and then dried to obtain a mixed powder. Put it, 192g of the binder of the above ingredients, and the mixed powder into the internal mixer for mixing. The mixing temperature is 170°C and the rotation speed is 30r / min. After the mixture is in a molten state, continue mixing for 2 hours, and then cool Then remove the feed.

[0035] (2) Injection molding: After crushing the feed material, it is formed by an injection molding machine at an injection temperature o...

Embodiment 3

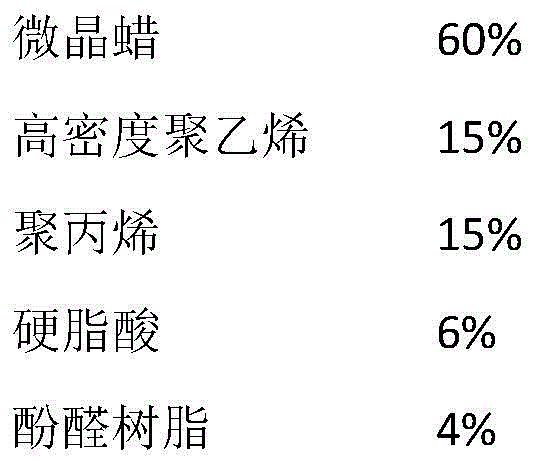

[0041] A binder for injection molding of aluminum nitride ceramics of the present invention, the binder composition is as follows:

[0042]

[0043]

[0044] The specific process steps of the binder for injection molding of aluminum nitride ceramics and the injection molding process of aluminum nitride of this embodiment are as follows:

[0045] (2) Feed material preparation: first, 1000 g (0.65%) of aluminum nitride powder and 30 g of sintering aid yttrium oxide were ball milled and mixed in alcohol, and then dried to obtain a mixed powder. Put it, 192g of the binder and the mixed powder of the above ingredients into a kneader for kneading, the kneading temperature is 170°C, and the rotation speed is 30r / min. After the mixture is in a molten state, continue kneading for 1h, and then cool Remove feed.

[0046] (3) Injection molding: After crushing the feed material, it is formed by an injection molding machine at an injection temperature of 160° C. to obtain an aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com