Isopropyl ether-isopropyl alcohol azeotrope distillation separation method based on choline chloride deep eutectic solvent

A technology of deep eutectic solvent and choline chloride, which is applied in ether separation/purification, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve problems that have not been seen, and achieve low equipment investment, flexible operation, and no waste The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

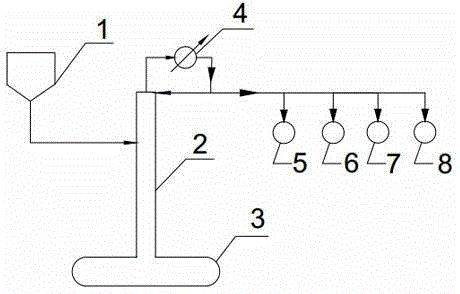

Image

Examples

Embodiment 1

[0012] Embodiment 1: adopt batch extraction rectification device, drop into 500 L isopropyl ether-isopropanol azeotropic mixture (wherein isopropyl ether 80%, isopropanol 20%, are mass percent) in heating kettle, extraction agent is Choline chloride and ethylene glycol deep eutectic solvent, its composition molar ratio is 1:2, turn on the heat source of heating kettle and the cold source of condenser, wait for a period of time after the top reflux of extraction and rectification column, the temperature of the top of the column is stable, add extraction The feed position of the extractant is close to the top of the tower, the speed of adding the extractant is controlled to 300 L / h, and the total reflux operation is performed. When the temperature of the top of the extractive distillation tower is 68-69°C, the content of isopropyl ether in the distillate is ≥ 99% start to discharge, the reflux ratio is 3:1, and the discharge speed is 200 L / h. When the temperature at the top of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com