L-threonine genetic engineering production bacteria

A technology of genetic engineering and threonine, which is applied in the field of L-threonine genetic engineering to produce bacteria, can solve the problems of increasing industrial production costs, achieve increased yield and sugar-acid conversion rate, wide industrial application prospects, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

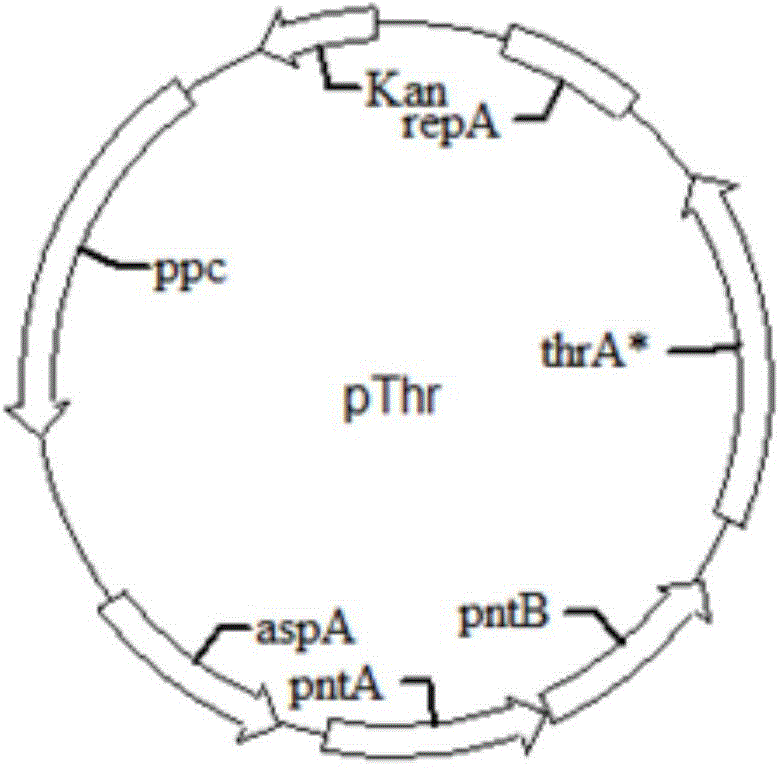

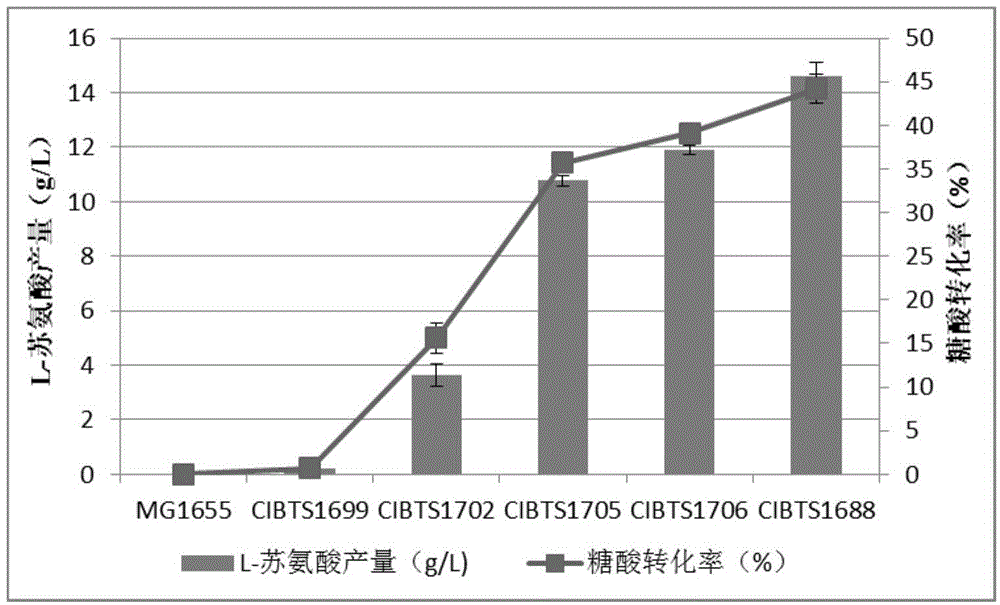

Method used

Image

Examples

Embodiment 1

[0057] Example 1 : Preparation of bacterial strain MG1655 (Δtdh) knocking out tdh gene

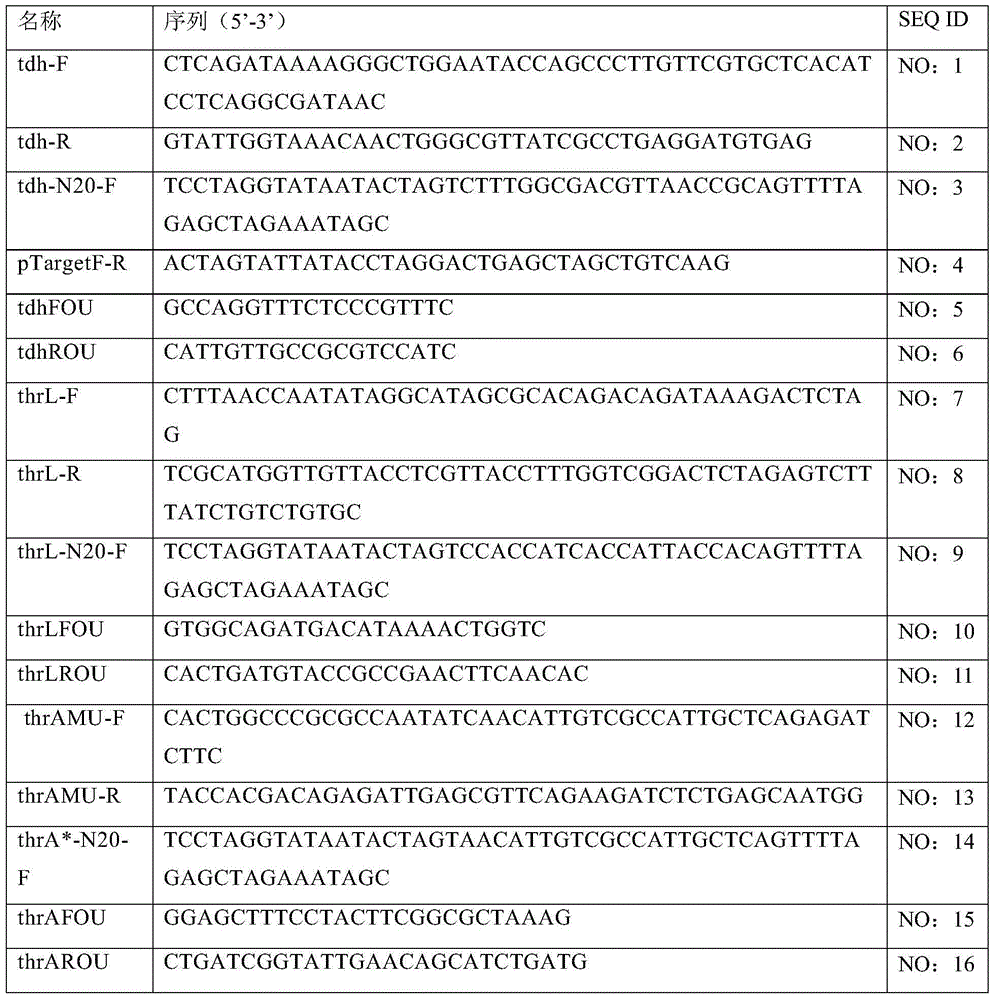

[0058] (1) PCR amplification: using tdh-F / tdh-R as primers and templates, PCR amplifies the tdh (HR) fragment, about 100bp, and recovers from the gel;

[0059] (2) Competent cell preparation: The pCas plasmid (sourced from literature: Multigene Editing in the Escherichia coli Genome via the CRISPR-Cas9System, Jiang Y, Chen B, et al. Appl. Environ Microbiol, 2015) was transformed into MG1655 (purchased In CGSC (E.coli Genetic Stock Center, Yale University, New Haven, Connecticut, USA)) competent cells (transformation methods and competent preparation methods refer to "Molecular Cloning III", Chapter 1, page 96), pick MG1655 / pCas single colony was cultured in a 4ml LB test tube containing kanamycin at 30°C and 220r / min, at bacterial concentration OD 600 Induction to OD was performed by adding arabinose at a final concentration of 10 mM one hour before 0.4 600 is 0.4;

[0060] (3) tdh-N...

Embodiment 2

[0063] Example 2 : Preparation of strain MG1655 (Δtdh, ΔthrL) knocking out the thrL gene

[0064] (1) PCR amplification: using thrL-F / thrL-R as primers and templates, PCR amplifies the thrL (HR) fragment, about 100bp;

[0065] (2) Competent cell preparation: transform the pCas plasmid into the MG1655(Δtdh) competent cells obtained in Example 1 (for both the transformation method and the competent preparation method, refer to page 96, Chapter 1 of Molecular Cloning III), pick MG1655(Δtdh) / pCas single colonies were placed in 4ml LB test tubes containing kanamycin, and the preparation method was the same as in Example 1(2);

[0066] (3) ThrL-N20-Spec plasmid construction: using pTargetF-cadA plasmid as a template, thrL-N20-F / pTargetF-R as primers, PCR amplifies the thrL-N20 fragment, about 2.2kb, and self-ligates after DpnI digests the PCR fragment , to obtain the thrL-N20-Spec plasmid;

[0067] (4) Electroporation: The thrL (HR) fragment and thrL-N20-Spec plasmid were elec...

Embodiment 3

[0069] Example 3 : Preparation of strain MG1655 (Δtdh, ΔthrL, thrA* (G433R) with mutant thrA* (G433R) gene

[0070] (1) PCR amplification: using thrAMU-F / thrAMU-R as primers and templates, PCR amplifies the thrA*(HR) fragment, about 100bp;

[0071] (2) Competent cell preparation: transform the pCas plasmid into the MG1655 (Δtdh, ΔthrL) competent cells obtained in Example 2 (for both the transformation method and the competent preparation method, refer to page 96 of Chapter 1 of Molecular Cloning III), Pick a single colony of MG1655 (Δtdh, ΔthrL) / pCas in a 4ml LB test tube containing kanamycin, and prepare the competent method as in Example 1 (2);

[0072] (3) ThrA*-N20-Spec plasmid construction: use pTargetF-cadA plasmid as a template, thrA*-N20-F / pTargetF-R as primers, PCR amplify the thrA*-N20 fragment, about 2.2kb, and digest the PCR fragment with DpnI After self-connection, the thrA*-N20-Spec plasmid was obtained;

[0073] (4) Electroporation: Electrotransform the thrA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com