Preparation method of copper-doped coated electrode for treating printing and dyeing wastewater

A coating electrode, printing and dyeing wastewater technology, applied in textile industry wastewater treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problems of high cost of doping platinum elements, difficult control of electroplating conditions, complex coating composition and other problems , to achieve high electrocatalytic activity, facilitate large-scale industrial production, and simple electrode process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

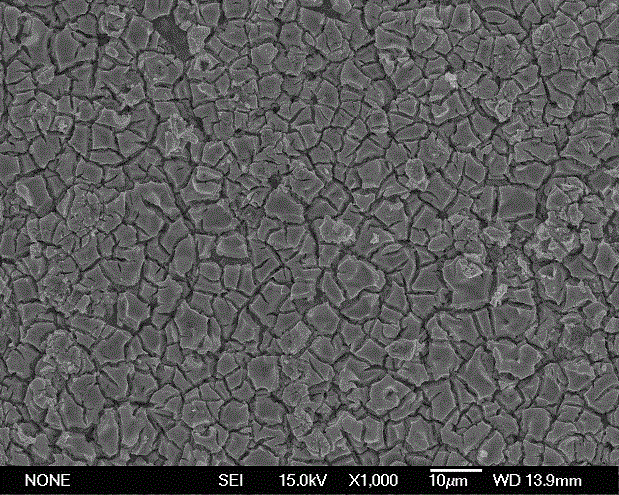

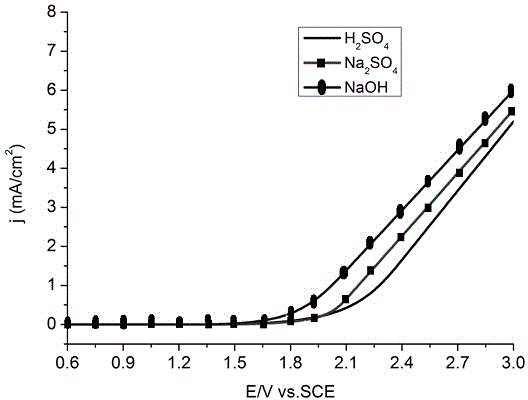

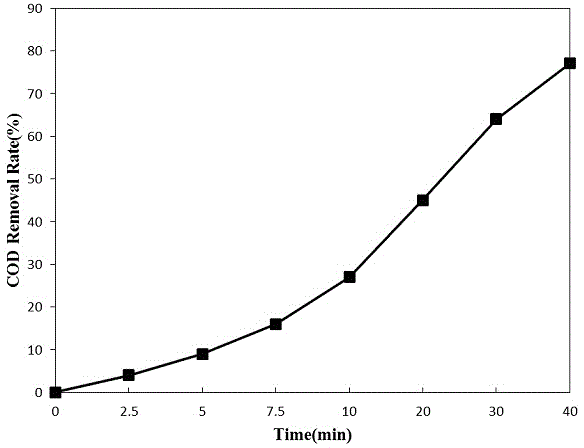

[0023] In this embodiment, a method for preparing a copper-doped coated electrode for treating printing and dyeing wastewater includes the following steps:

[0024] a. Titanium substrate pretreatment: use a pure titanium plate as the titanium substrate, polish the surface of the pure titanium plate with a polishing machine, immerse the pure titanium plate in a NaOH solution with a mass concentration of 10%, and heat it at 80°C for 2 hours to remove oil , and then immerse the pure titanium plate in oxalic acid with a mass concentration of 20%, treat it for 1~2h under the slightly boiling state of oxalic acid, and then rinse the pure titanium plate with deionized water for later use;

[0025] b. Preparation of intermediate layer coating liquid: 20gSnCl 4 ·5H 2 O, 1.3gSbCl 3 and 0.172gMnSO 4 Dissolve in isopropanol together, add HCl solution to adjust the pH value to 1, and ultrasonically oscillate for 1 hour at the same time to mix the solution evenly to obtain the intermedia...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, especially in that:

[0037] In this embodiment, a method for preparing a copper-doped coated electrode for treating printing and dyeing wastewater includes the following steps:

[0038] a. Titanium substrate pretreatment: this step is the same as in Example 1;

[0039] B. the preparation of middle layer coating liquid: this step is identical with embodiment one;

[0040] c. Brushing method is used to prepare the intermediate layer: this step is the same as that of Example 1;

[0041] d. Preparation of active layer coating solution: 20gSnCl 4 ·5H 2 O, 1.3gSbCl 3 and 0.138gCu(NO 3 ) 2 ·3H 2 Dissolve O in isopropanol together, add HCl solution to adjust the pH value to 1, and ultrasonically oscillate for 1 hour at the same time to mix the solution evenly to obtain the active layer coating solution. The mass percentage of Cu doping amount in this step is 1%;

[0042] e. Preparation of active layer by brushing m...

Embodiment 3

[0046] This embodiment is basically the same as the previous embodiment, and the special features are:

[0047] In this embodiment, a method for preparing a copper-doped coated electrode for treating printing and dyeing wastewater includes the following steps:

[0048] a. Titanium substrate pretreatment: this step is the same as in Example 1;

[0049] B. the preparation of middle layer coating liquid: this step is identical with embodiment one;

[0050] c. Brushing method is used to prepare the intermediate layer: this step is the same as that of Example 1;

[0051] d. Preparation of active layer coating solution: 20gSnCl 4 ·5H 2 O, 1.3gSbCl 3 and 0.414gCu(NO 3 ) 2 ·3H 2 Dissolve O in isopropanol together, add HCl solution to adjust the pH value to 1, and ultrasonically oscillate for 1 hour at the same time to mix the solution evenly to obtain the active layer coating solution. The doping amount of Cu in this step is 3% by mass;

[0052] e. Preparation of active layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com