Heat-resistant wave-absorbing material and preparation method thereof

A wave-absorbing material and high-temperature-resistant technology, which is applied in the field of radar absorbing materials, can solve the problems of difficulty in achieving gradient distribution of dielectric properties, poor toughness of particle-reinforced ceramic materials, and difficulty in preparing large and complex components, etc., to achieve low price and anti-oxidation The effect of strong performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

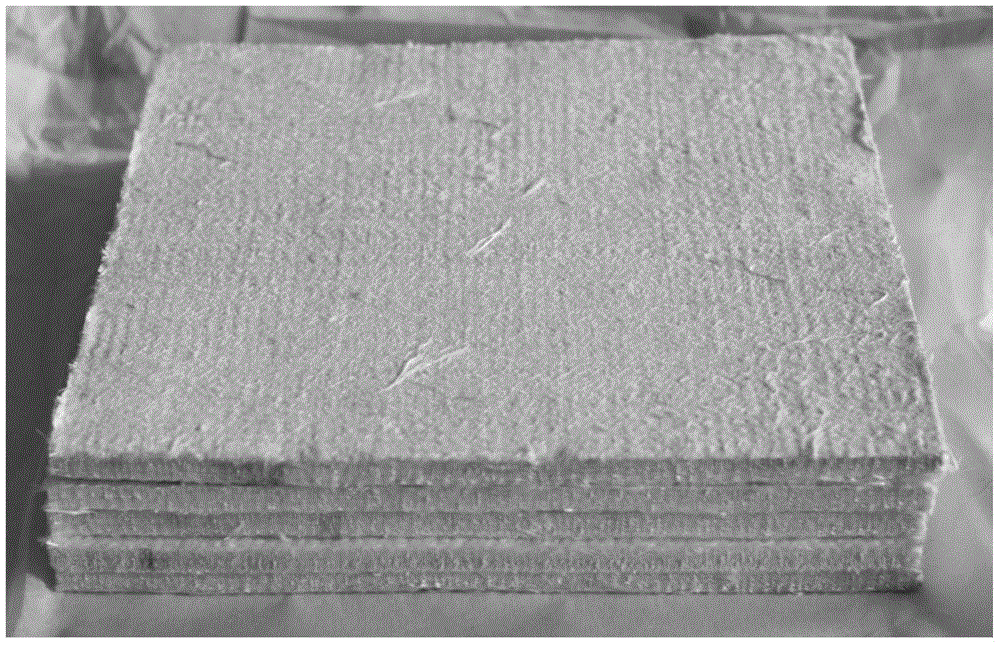

[0039] A high-temperature-resistant wave-absorbing material of the present invention is a composite material with quartz as a matrix and quartz fiber needle-punched parts as a reinforcing phase. The composite material contains chopped carbon fibers with a length of 5mm, and the chopped carbon fibers in the wave-absorbing material The volume content is 0.005g / cm 3 , the bulk density of the quartz fiber needled parts is 0.444g / cm 3 .

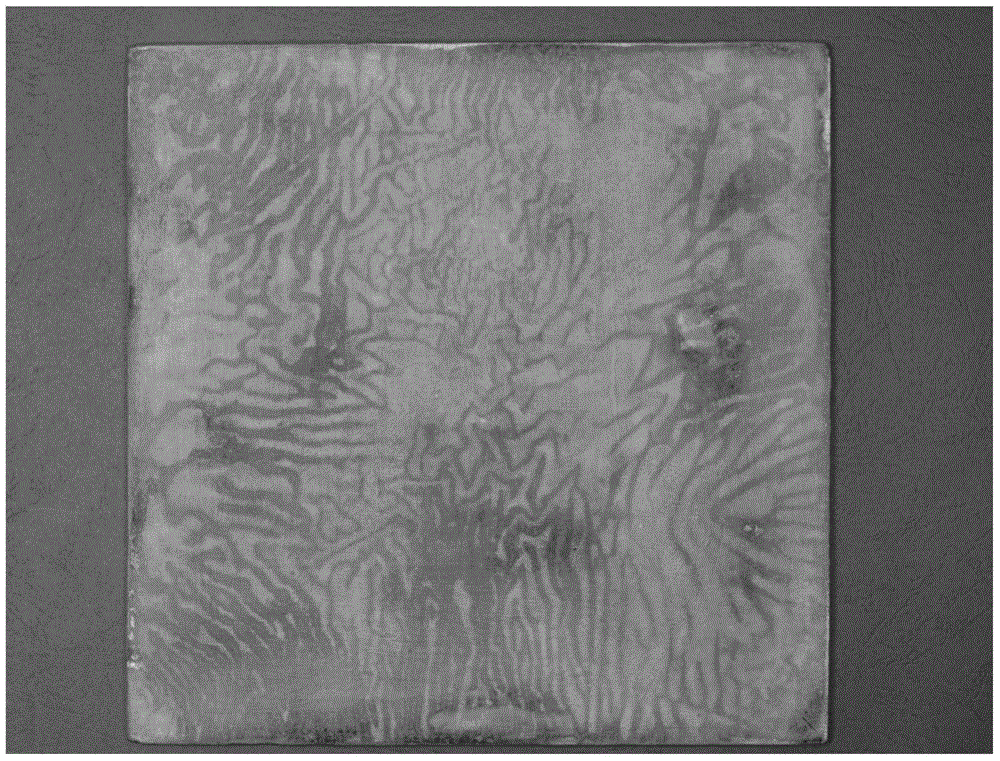

[0040] In order to improve the anti-oxidation performance of the absorbing material, a glass coating with a thickness of 0.1mm is also provided on the surface of the absorbing material.

[0041] The preparation method of the high-temperature-resistant wave-absorbing material of this embodiment includes the following steps:

[0042] 1) Select 1K chopped carbon fiber with a length of 5mm and an area density of 100±5g / m 2 Quartz fiber mesh tire, surface density is 285±5g / m 2 The quartz fiber plain cloth and silica sol (silica sol particle size is...

Embodiment 2

[0051] A high-temperature-resistant wave-absorbing material of the present invention is a composite material with quartz as a matrix and quartz fiber needle-punched parts as a reinforcing phase. The composite material contains chopped carbon fibers with a length of 6mm, and the chopped carbon fibers in the wave-absorbing material The volume content is 0.004g / cm 3 , the bulk density of the quartz fiber needled parts is 0.437g / cm 3 .

[0052] In order to improve the anti-oxidation performance of the absorbing material, a glass coating with a thickness of 0.12mm is also provided on the surface of the absorbing material.

[0053] The preparation method of the high-temperature-resistant wave-absorbing material of this embodiment includes the following steps:

[0054] 1) Select 1K chopped carbon fiber with a length of 6mm and an area density of 100±5g / m 2 Quartz fiber mesh tire, surface density is 285±5g / m 2 The quartz fiber plain cloth and silica sol (silica sol particle size i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com