Benzene-propyl alcohol azeotrope continuous extractive distillation technology based on choline chloride/urea low co-melting solvent

A technology of low eutectic solvent and choline chloride, which is applied in the preparation of hydroxyl compounds, distillation purification/separation, and preparation of organic compounds, etc., achieving the effects of low cost, novel technology and low operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

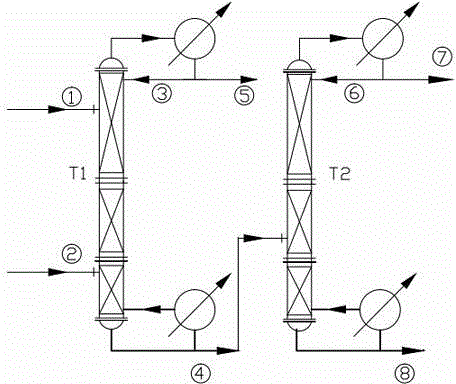

[0019] A kind of benzene and propanol azeotrope continuous extraction and rectification process based on choline chloride / urea low eutectic solvent, its process flow chart is as follows figure 1 shown. The number of trays in T1 is 50, 90wt% ethylene glycol and 10wt% choline chloride / urea are used as extractants, and they are added from the third tray with a flow rate of 300kg / hr. The mixture of benzene and propanol is added from the 40th tray, the flow rate is 100kg / hr, and the mass fraction of benzene is 80%. Operated under normal pressure, the reflux ratio at the top of the tower is controlled at 3:1, the temperature at the top of the tower is 79.5-81°C, and the temperature at the bottom of the tower is 187-189°C. After analysis, the top product is benzene with a purity higher than 99%. The bottom of the tower enters into T2. T2 has 50 trays, the reflux ratio is 4:1, the feed is from the 40th tray, the operating condition is normal pressure, the temperature at the top of t...

Embodiment 2

[0021] The two-tower process flow of the extractive distillation tower is the same as that in Example 1. Use 85wt% ethylene glycol and 15wt% choline chloride / urea as the extractant, the number of trays is 30, feed from the third tray, and the flow rate is 200kg / hr. The mixture of benzene and propanol is added from the 22nd theoretical plate, the flow rate is 100kg / hr, and the composition is the same as that of Example 1. T1 operates at normal pressure with a reflux ratio of 3:1. At this time, the temperature at the top of the tower is 79.5-81°C, and the temperature at the bottom of the tower is 187-189°C. The top product was analyzed by gas chromatography to obtain a benzene product with a purity higher than 99%. The number of trays in T2 is 60, and other operating conditions are the same as in Example 1, and the bottoms of the tower are returned to T1 for recycling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com