Phenolic aldehyde weak gel control and flooding agent for rapid gelling of low temperature oil reservoirs

A weak gel, low-temperature oil technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of unsuitable for large-dose deep-level flood control, complex preparation process of cross-linking agent, and difficult to control gel formation time. , to achieve the effect of promoting low-temperature gel forming rate, convenient configuration and good gel-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

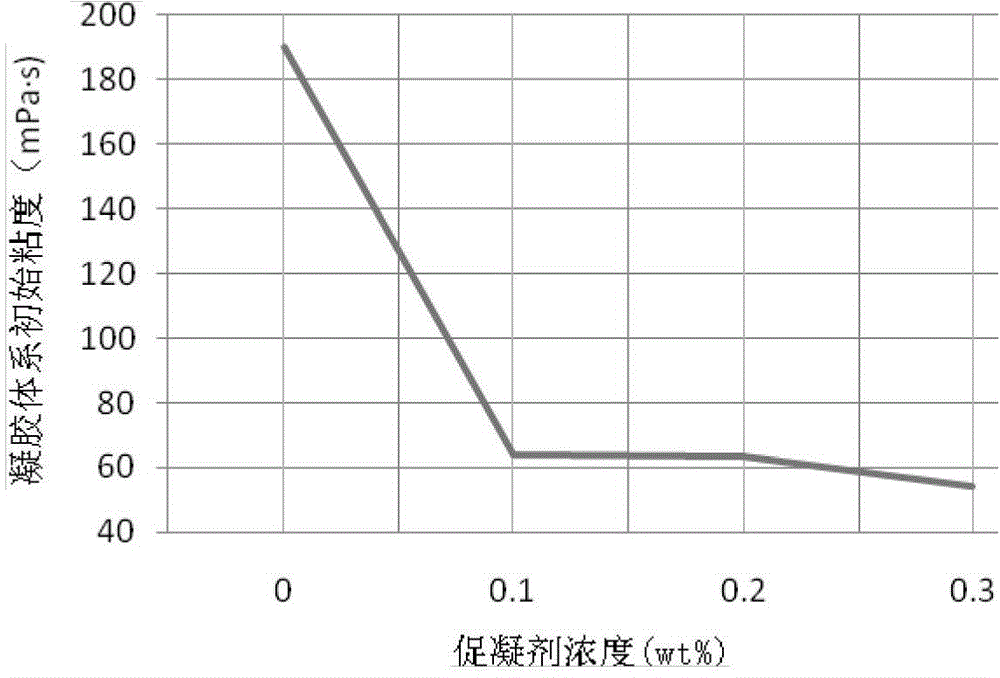

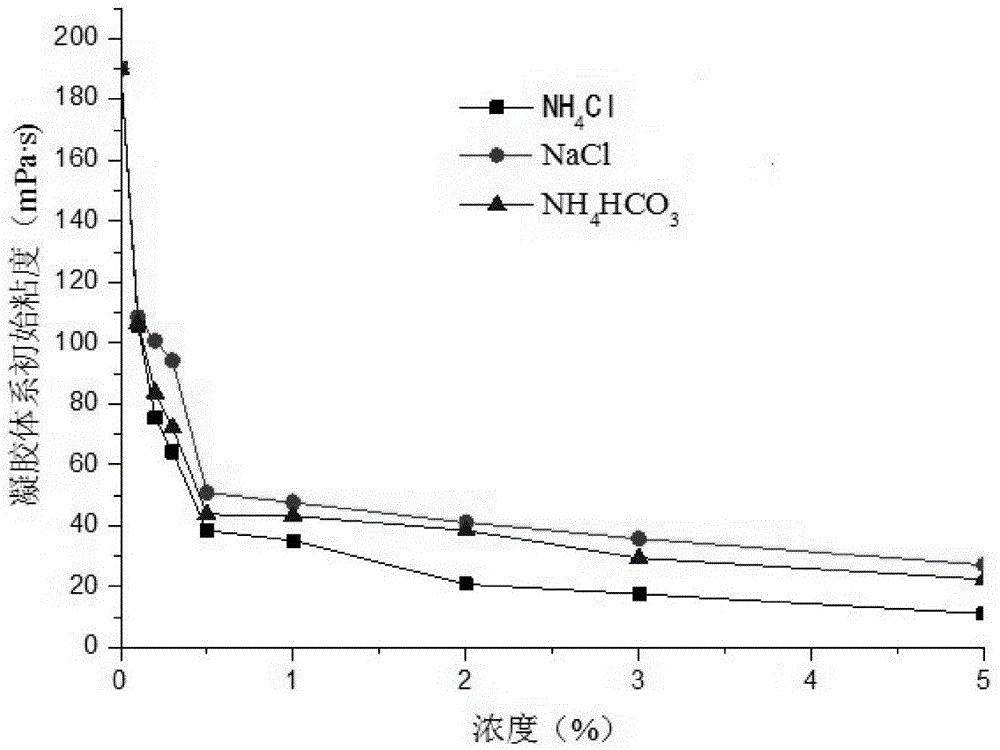

[0039] The composition of the phenolic weak gel modifier is as follows: comb-shaped salt-resistant polymer KYPAM (molecular weight: 1600×10 4 g / mol, initial viscosity 190.1mPa s, produced by Beijing Hengju Chemical Group) concentration is 0.2%, formaldehyde+hexamethylenetetramine concentration is 0.1%, hydroquinone+resorcinol concentration is 0.02%, The ammonium hydroxide concentration ranges from 0.1 to 0.3%, and the rest is clear water. See Table 2 for gel formation.

[0040] The gelling situation of the regulating and displacing agent prepared in the embodiment 1 of table 2

[0041]

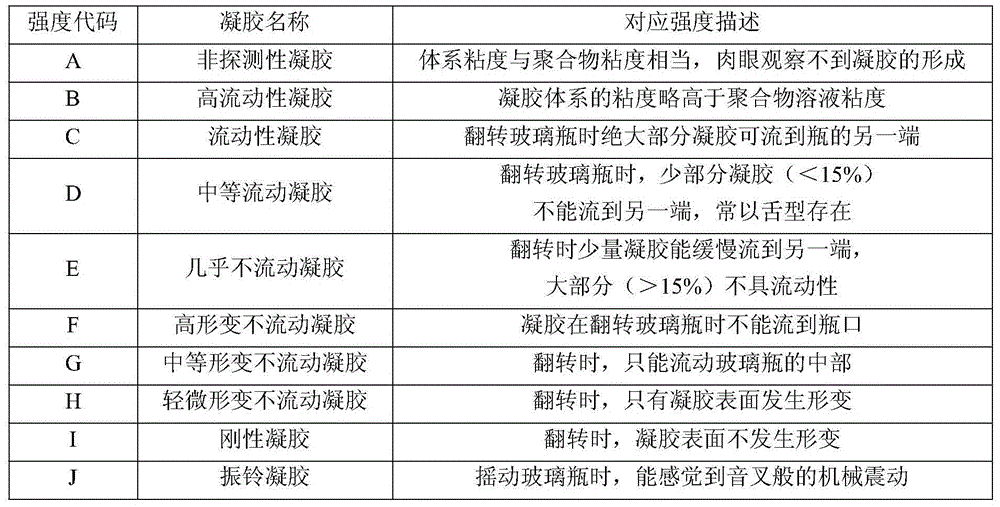

[0042] The gelation time is 5-16 hours, the final gel strength is grade G, and no syneresis occurs in 90 days.

Embodiment 2

[0044] The composition of the phenolic weak gel modifier is as follows: HPAM (molecular weight: 1600×10 4 g / mol, initial viscosity 196.0mPa s) concentration is 0.2%, formaldehyde + phenolic concentration is 0.5%, resorcinol concentration is 0.02%, ammonium acetate concentration ranges from 0.1 to 0.3%, ammonium bicarbonate concentration range 0% to 0.2%, and the rest is clear water. See Table 3 for gel formation.

[0045] The gelling situation of the regulating and displacing agent prepared in the embodiment 2 of table 3

[0046]

[0047] The gelation time is 5-10 hours, the final gel strength is G, and no syneresis occurs in 90 days.

Embodiment 3

[0049] The composition of the phenolic weak gel modifier is as follows: HPAM (molecular weight: 1600×10 4 g / mol, initial viscosity 196.0mPa s) concentration is 0.2%, formaldehyde concentration is 0.2%, hydroquinone+catechol+resorcinol concentration is 0.02%, ammonium chloride concentration range is 0.1~ 0.3%, the ammonium bicarbonate concentration ranges from 0.1 to 0.2%, and the rest is clear water. See Table 4 for gelling conditions.

[0050] The gelling situation of the regulating and displacing agent prepared in the embodiment 3 of table 4

[0051]

[0052] The gelation time is 5-10 hours, the final gel strength is G, and no syneresis occurs in 90 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial viscosity | aaaaa | aaaaa |

| Initial viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com