A water-based cutting fluid for nuclear power equipment processing and its dilution

A water-based, cutting fluid technology, used in the petroleum industry, lubricating compositions, etc., can solve the problems of difficult cutting, no cutting fluid, etc., to achieve the effect of no fire hazard, reduced processing time, and guaranteed processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

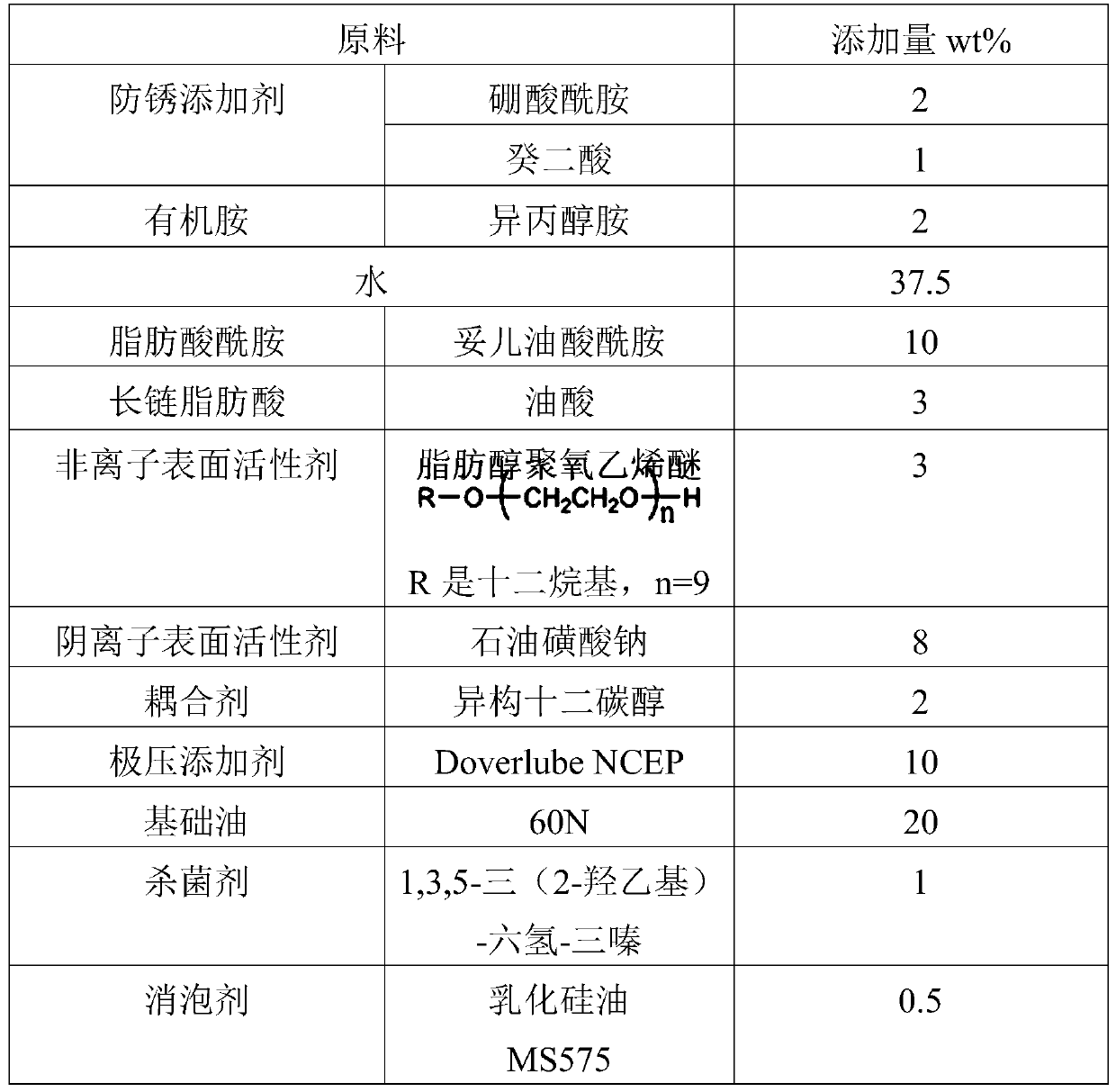

[0029] raw material:

[0030]

[0031] All raw materials are heated and dissolved, and then stirred evenly to obtain a water-based cutting fluid for nuclear power equipment processing.

Embodiment 2

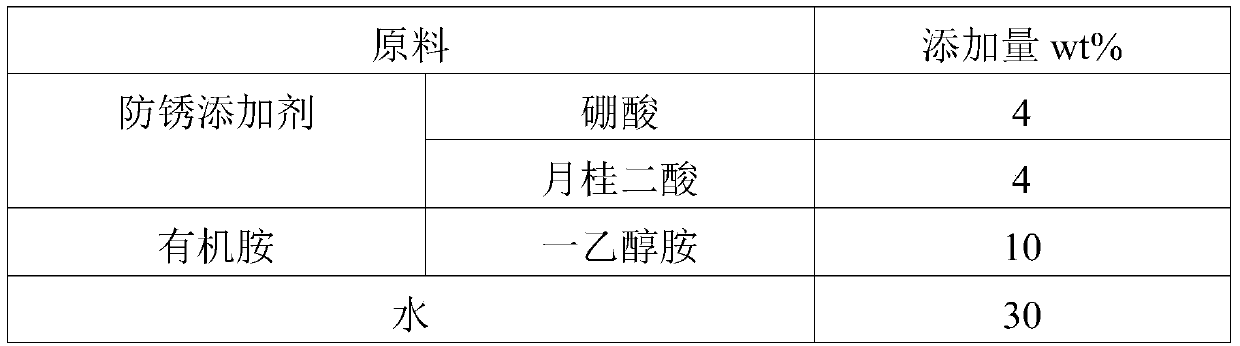

[0033] raw material:

[0034]

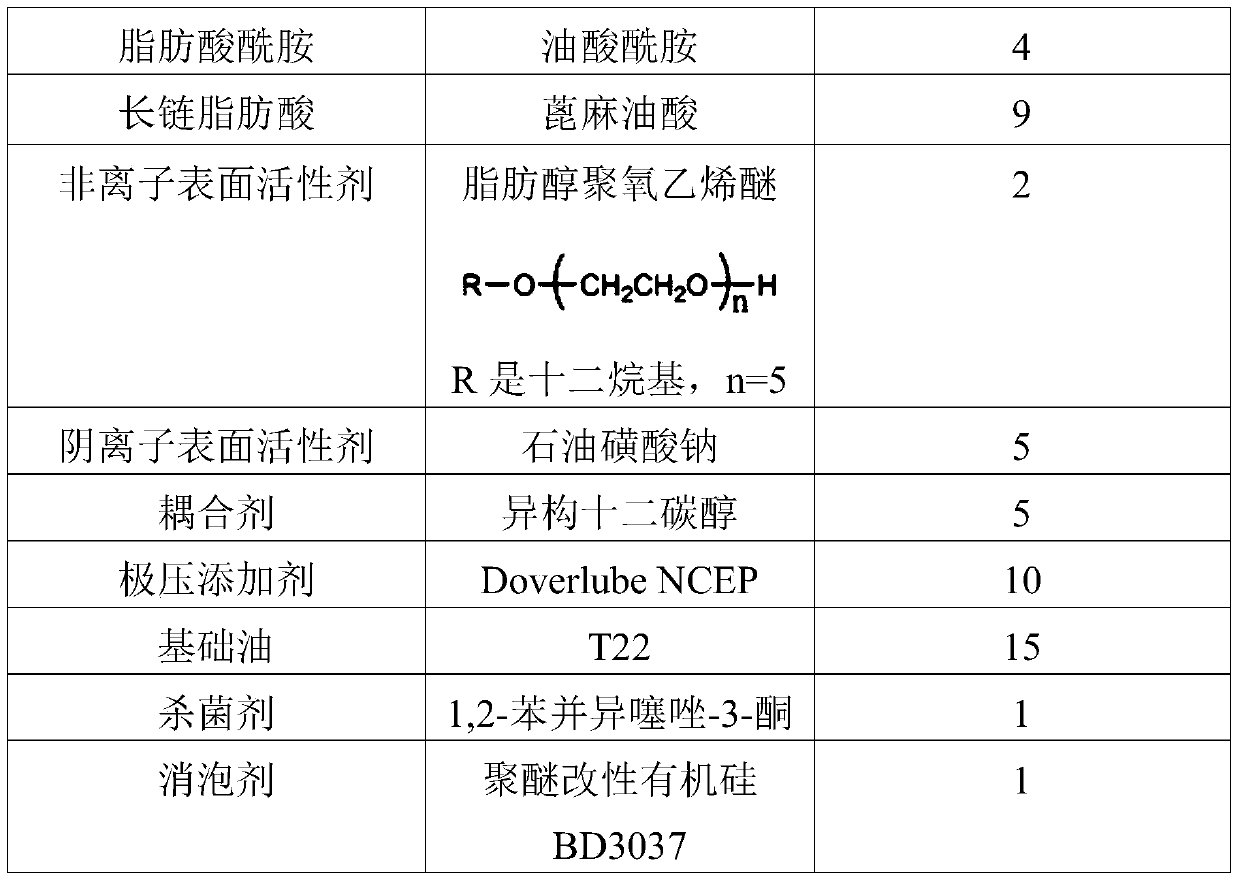

[0035]

[0036] All raw materials are heated and dissolved, and then stirred evenly to obtain a water-based cutting fluid for nuclear power equipment processing.

Embodiment 3

[0038] raw material:

[0039]

[0040]

[0041] All raw materials are heated and dissolved, and then stirred evenly to obtain a water-based cutting fluid for nuclear power equipment processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com