Novel sunflower seed beer

A technology of sunflower seeds and beer, which is applied in the direction of beer brewing, etc., can solve the problems of affecting the beer's foam retention and flavor, limiting the health care effect of beer, and low dietary fiber content, so as to achieve good complexation ability, good health care effect, and reduce Effect of Calcium and Oxalic Acid Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

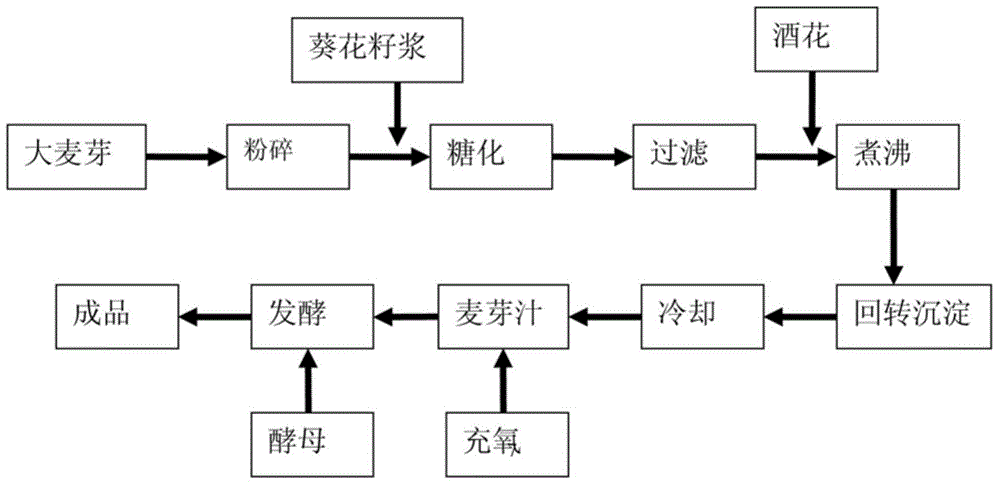

Method used

Image

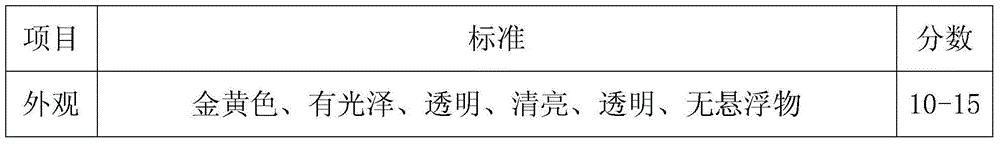

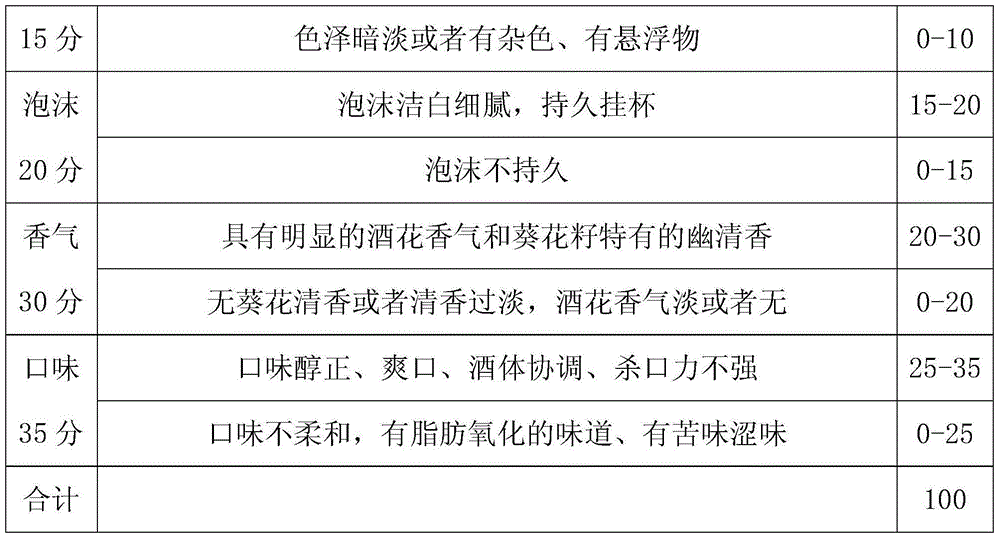

Examples

Embodiment 1

[0035] Preparation steps of sunflower seed slurry:

[0036] Step 1: Clean the fresh sunflower seeds and soak them in salt water at room temperature for 1 hour, remove and drain;

[0037] Step 2: Add sodium citrate solution with a mass concentration of 0.02% to the sunflower seeds in an amount sufficient to submerge all the sunflower seeds, and heat in a water bath at 85°C for 30 minutes;

[0038] Step 3: filter and collect the sunflower seeds, and dry until the moisture content is 30%;

[0039] Step 4: Collect sunflower kernels, add 5 times the weight of vitamin C solution for beating;

[0040] Step 5: Add food-grade alkaline lipase and papain to the sunflower seed slurry for enzymolysis in a water bath, the addition amounts are 0.2g / L and 0.1g / L, and the enzyme activities are 100000U / g and 50000U / g respectively, The amount added is calculated by enzyme activity;

[0041] Step 6: Obtain sunflower seed slurry by filtering after high temperature deactivation.

Embodiment 2

[0043] Preparation steps of sunflower seed slurry:

[0044]Step 1: Clean the fresh sunflower seeds and soak them in salt water at room temperature for 2 hours, remove and drain;

[0045] Step 2: adding sodium citrate solution with a mass concentration of 0.05% to the sunflower seeds and heating in a 90° C. water bath for 30-40 minutes;

[0046] Step 3: collecting the sunflower seeds by filtration, and drying to a moisture content of 35%;

[0047] Step 4: Collect sunflower kernels, add 7 times the weight of vitamin C solution for beating;

[0048] Step 5: Add food-grade alkaline lipase and papain to the sunflower seed slurry for enzymolysis in a water bath, the addition amount is 0.3g / L and 0.15g / L; the enzyme activity is 100000U / g and 50000U / g respectively, The amount added is calculated by enzyme activity;

[0049] Step 6: Obtain sunflower seed slurry by filtering after high temperature deactivation.

Embodiment 3

[0051] Preparation steps of sunflower seed slurry:

[0052] Step 1: Clean the fresh sunflower seeds and soak them in salt water at room temperature for 1 hour, remove and drain;

[0053] Step 2: adding sodium citrate solution with a mass concentration of 0.05% to the sunflower seeds and heating in a water bath at 85° C. for 40 minutes;

[0054] Step 3: collecting the sunflower seeds by filtration, and drying to a moisture content of 30%;

[0055] Step 4: Collect sunflower kernels, add 7 times the weight of vitamin C solution for beating;

[0056] Step 5: Add food-grade alkaline lipase and papain to the sunflower seed slurry for enzymolysis in a water bath, the addition amount is 0.2g / L and 0.15g / L; the enzyme activity is 100000U / g and 50000U / g respectively, The amount added is calculated by enzyme activity;

[0057] Step 6: Obtain sunflower seed slurry by filtering after high temperature deactivation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com