Preparation and applications of composite SBA-15 molecular sieve catalysts

A catalyst and reaction technology, applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problems of long synthesis route, large consumption of raw materials, serious environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

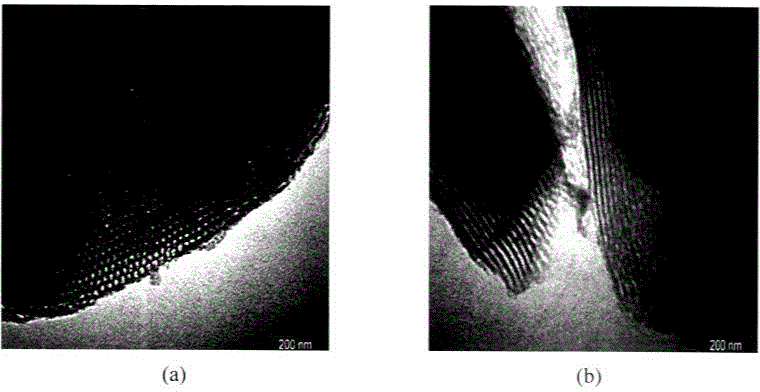

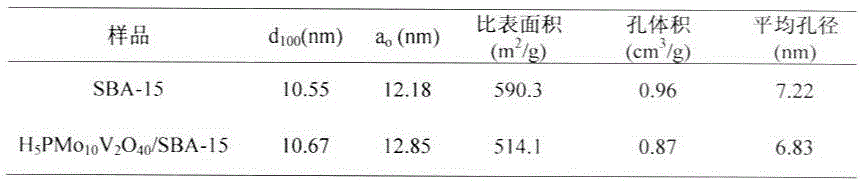

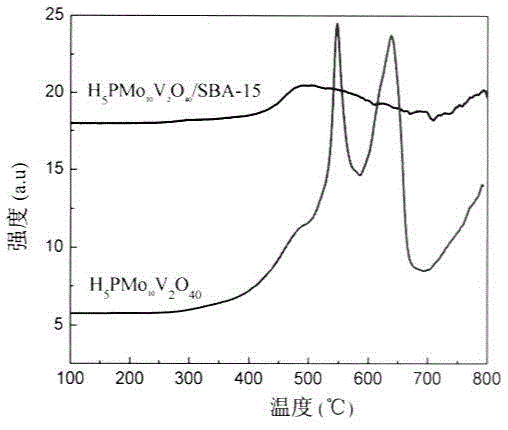

Image

Examples

Embodiment 1

[0020] Take the quantitative Na 2 HPO 4 ·12H 2 O was dissolved in distilled water and mixed with 10.6 g Na 2 CO 3 The aqueous solutions were mixed, stirred for a certain period of time, and 9.1 g of V was added slowly. 2 O 5 , heated to boiling, reacted for 30min, took 35.3g MoO 3 After being dissolved in distilled water, it was added to the above solution, heated at 90° C. for 30 min in a water bath, adjusted to pH value with 1:1 sulfuric acid, and cooled to room temperature with stirring. Add an appropriate amount of ether to extract and shake well, gradually add an appropriate amount of 1:1 sulfuric acid until layers appear, and the obtained red oily heteropolyether complex is in the middle layer. until it turns light yellow. Blow off the ether, dissolve the red solid in distilled water and place it in a vacuum desiccator. After the crystal film appears, put it in a refrigerator at 3°C to 5°C for crystallization to obtain H 5 PMo 10 V 2 O 40 ·xH 2 O heteropoly...

Embodiment 2

[0023] The H obtained by the method of Example 1 5 PMo 10 V 2 O 40 SBA-15 molecular sieve catalyst supported by heteropoly acid, used in the reaction of benzene oxidation to phenol, with 20%, 40%, 60%, 80% H respectively 5 PMo 10 V 2 O 40 Heteropolyacids, examine different H 5 PMo 10 V 2 O 40 The effect of heteropolyacid loading on catalyst performance. The specific catalytic reaction is as follows: add benzene, 25mL glacial acetic acid and catalysts of different qualities into a 50mL three-neck flask, keep stirring, and then slowly add a certain amount of H dropwise. 2 O 2 (30%), the reaction was carried out in a water bath at a certain reaction temperature, a sample was taken every 0.5 h, and the reaction product was analyzed by high performance liquid chromatography.

[0024] The reaction products were analyzed on HPLC-Agilent1100 high performance liquid chromatography, using C8 column (4.6×150mm) type chromatographic column, programmable ultraviolet detector, N...

Embodiment 3

[0027] Prepare 60% H according to Example 1 5 PMo 10 V 2 O 40 The SBA-15 molecular sieve catalyst supported by the heteropolyacid was used to carry out the experiment of oxidizing phenol with benzene according to the catalytic reaction of Example 2. Change the reaction time to 0.5h, 1h, 1.5h, 2h, 2.5h, 3h, 6h, and investigate the effect of time on the reaction.

[0028] Reaction conditions: in benzene and H 2 O 2 The molar ratio of the catalyst was 1:1, the catalytic reaction temperature was 70 °C, the catalyst dosage was 0.20 g, and the H of the catalyst prepared by the sol-gel method 5 PMo 10 V 2 O 40 The load is 60%. The reaction results are: with the increase of reaction time, the selectivity of phenol gradually increases, and when the reaction time reaches 2h, H 5 PMo 10 V 2 O 40 The phenol selectivity of / SBA-15 catalyst reaches a maximum of 80.72%, compared to H 5 PMo 10 V 2 O 40 The selectivity of the Figure 5 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com