A macro-preparation method of solar-grade ultra-high-purity nano-silicon powder

A nano-silica fume, solar technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of consumption of silicon-containing raw materials, high recovery cost, low purity, etc., and achieves a simple, easy, and compatible preparation method. Good, suitable for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

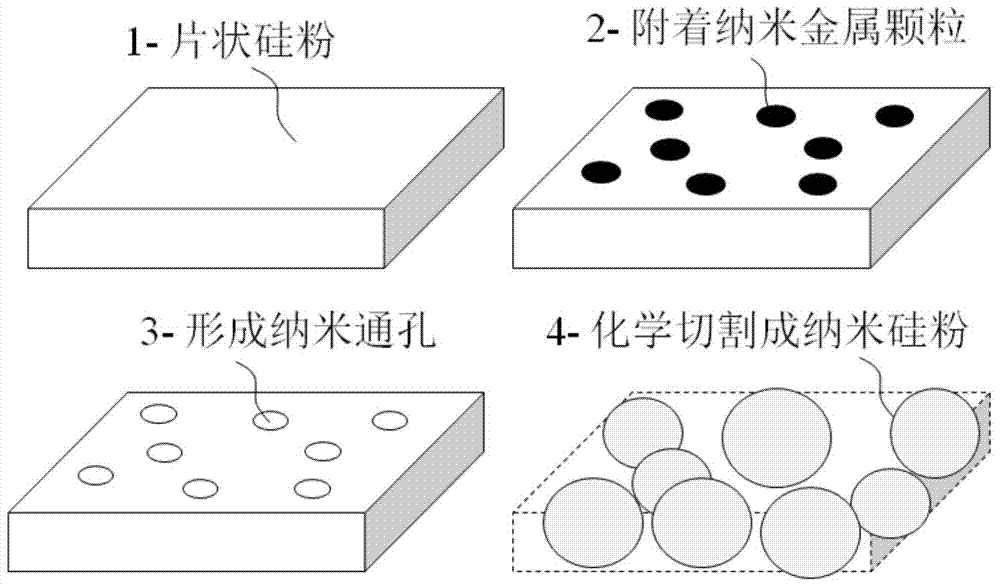

[0042] The invention discloses a macro-preparation method of solar-grade ultra-high-purity nano silicon powder. The method specifically includes the following steps:

[0043] S1. Use the flake silicon powder produced during the process of cutting solar-grade silicon ingots into silicon wafers by diamond wire as raw materials, and perform pretreatment;

[0044] Among them, the flake silicon powder has micron and submicron size, and the purity is 99.9999%.

[0045] The preprocessing in step S1 specifically includes:

[0046] First put the flake silicon powder into the HF solution with a mass percentage of 1-10% to remove SiO 2 For the oxide layer, the cleaning time is 60-1200 seconds, and the cleaning temperature is 5-30°C;

[0047] Then use deionized water to wash 3-5 times;

[0048] Put wet silica fume into N 2 Protective atmosphere furnace, drying at 120 ~ 200 ℃.

[0049] S2, putting the pretreated silicon powder into a first chemical solution containing metal ions, an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com