Three-tower device and method for recycling ethylene and ethane from dry gas through oil absorption

An oil absorption and absorption tower technology, which is applied in the field of catalytic cracking dry gas separation process, can solve the problems of limiting the application scope of the absorption method and the large investment of polymerization-grade ethylene, and achieves strong adaptability of raw materials, flexible absorption method, energy saving and low cost. effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

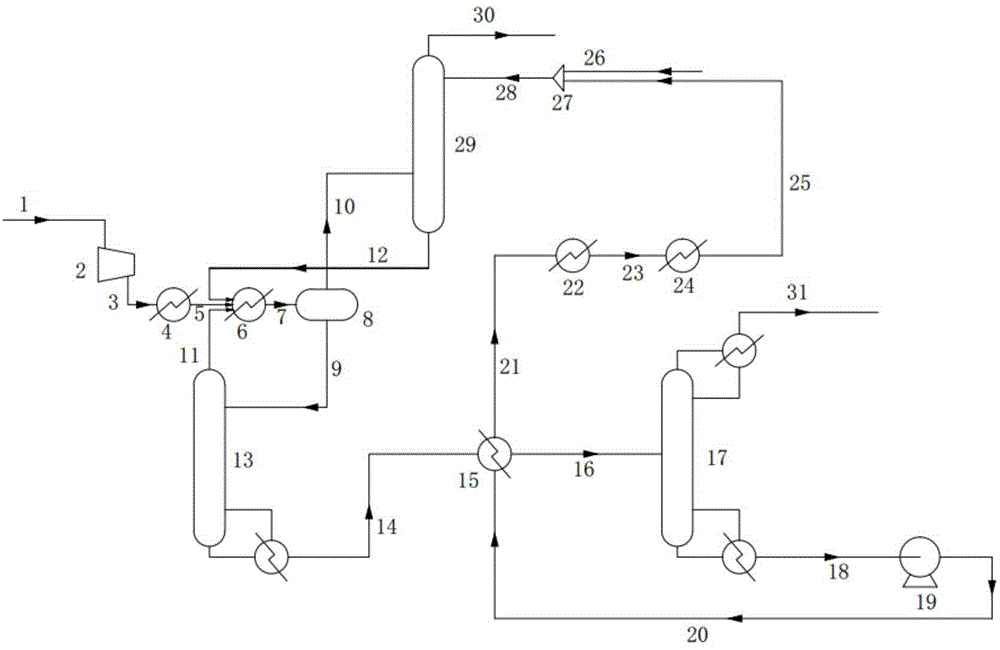

Image

Examples

Embodiment 1

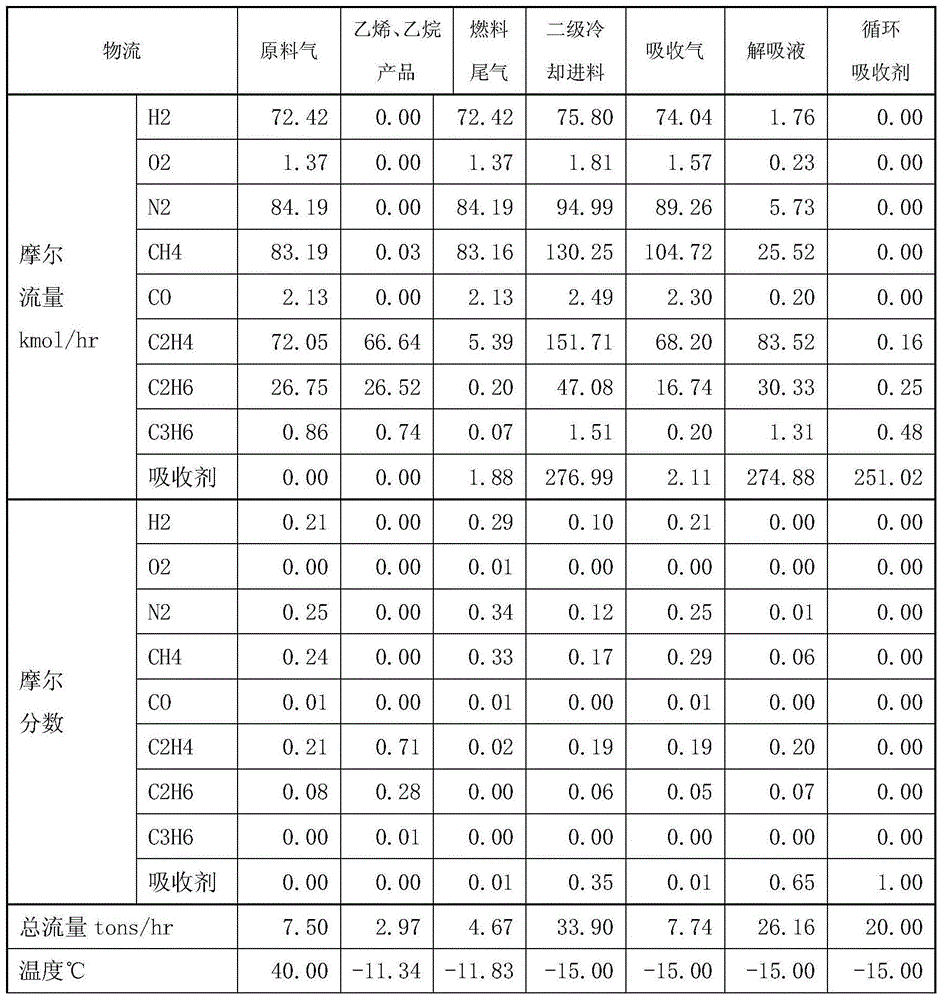

[0026] The molar composition of feed gas 1 is 21.1% H 2 +24.5%N 2 +24.3%CH 4 +21%C 2 h 4 +7.8%C 2 h 6 +0.2C 3 h 6 +0.4%O 2 +0.6% CO, mass flow rate 7.5 tons / hr, temperature 40°C. C5 is used as absorbent in the process, and the amount of recycled absorbent is 20 tons / hr.

[0027]The compressor 2 compresses the raw material gas 1 to 3.05Mpa, the raw material primary cooler 4 cools the compressed gas 3 to 32°C, and the raw material secondary cooler 6 cools the absorption liquid 12, the primary cooling gas 5, and the desorption gas 11 to -15°C. The separation tank 8 is adiabatically flashed at 3.05MPa. Absorption tower 29 has 12 theoretical plates, and its operating pressure is 3 MPa; desorption tower 13 has 10 theoretical plates, and its operating pressure is 3.05 MPa. The preheater 15 preheats the desorption liquid 14 to 132°C. The rectification column 17 has a theoretical plate number of 20, an operating pressure of 2.6 MPa, a reflux ratio of 2, and preheating liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com