Poly lactic acid-glycolic acid (PLGA)-polyethylene glycol (PEG)-PLGA triblock copolymer and preparation method thereof

A PLGA-PEG-PLGA, PLGA technology is applied in the field of PLGA-PEG-PLGA triblock copolymer and its preparation, which can solve the problems of long preparation cycle, optimize the post-processing process, reduce the harmfulness of the solvent, reduce the reaction The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

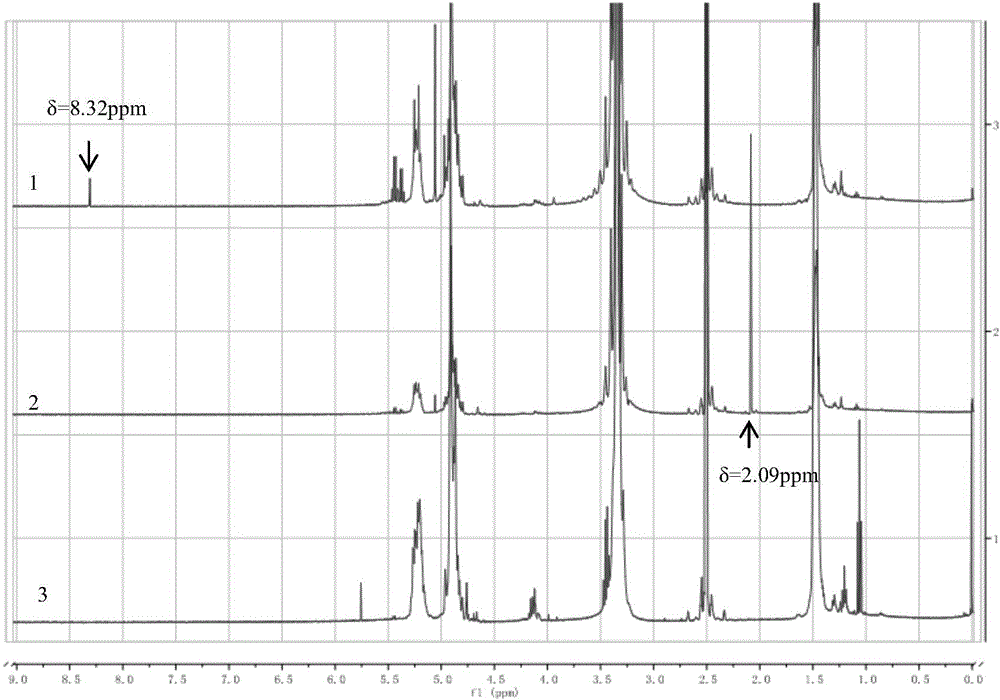

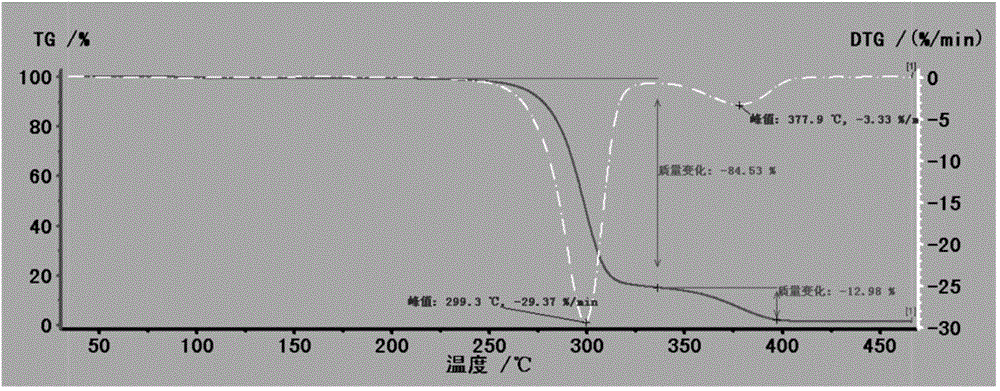

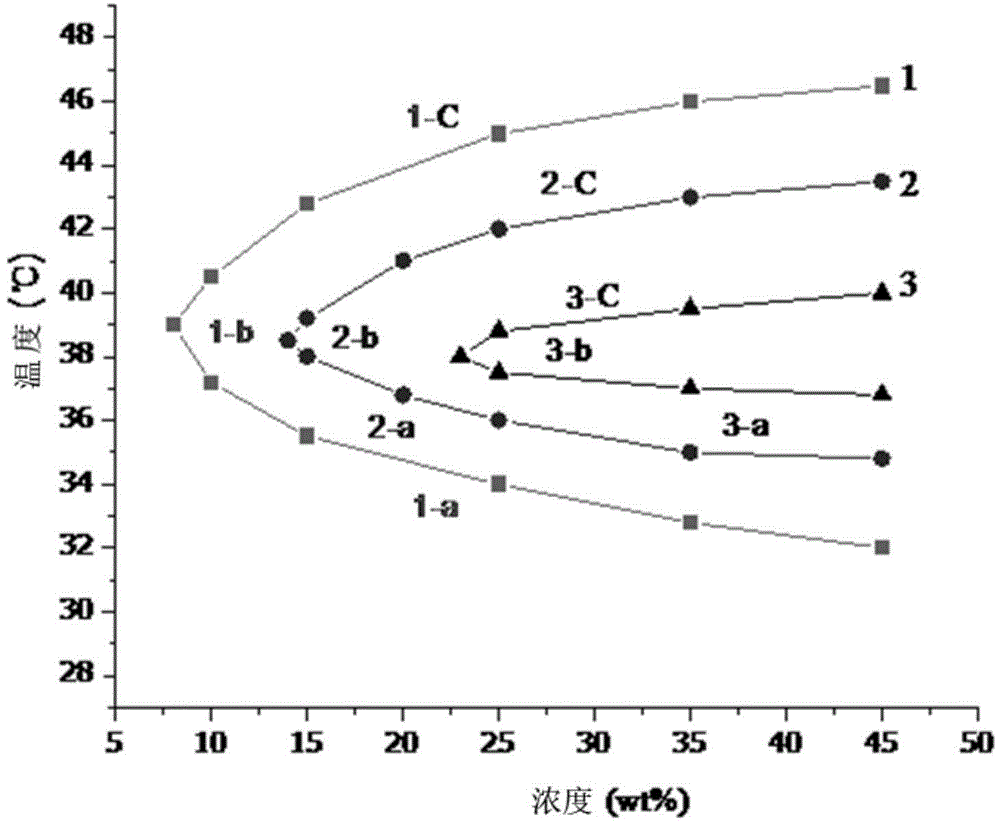

[0046] Embodiment 1 PLGA-PEG-PLGA triblock copolymer and its preparation

[0047] 1.1 Raw materials: L-lactic acid, analytically pure, Aladdin Reagent (Shanghai) Co., Ltd.; glycolic acid, analytically pure, Aladdin Reagent (Shanghai) Co., Ltd.; stannous chloride (SnCl 2 2H 2 O), superior grade, Anaiji Chemical (import); Methanesulfonic acid (MSA), superior grade, Anaiji Chemical (import); PEG (PEG-2000, PEG-6000, PEG-8000, PEG -10000, PEG-20000), analytically pure, Aladdin Reagent (Shanghai) Co., Ltd.

[0048] 1.2 Instruments

[0049]Fourier Transform Infrared Spectrometer (FT-IR): Nicolet Avatar 330, American Thermoelectric Company; Nuclear Magnetic Resonance Spectrometer (NMR): Avance Ⅲ 400MHz, Swiss Bruker Company; Gel Permeation Chromatography (GPC): Breeze2, American Waters Company; UV- Visible Spectrophotometer (UV-Vis): UV-2100, Shimadzu Corporation; Synchronous Thermal Analyzer (SDT): SDT Q600, American TA Instruments; Intelligent Release Tester: ZRS-8GD, Tianda Tia...

Embodiment 2

[0064] The difference between this embodiment and Example 1 is that the steps of synthesizing PLGA-PEG-PLGA copolymer are as follows:

[0065] (1) Weigh a certain amount of PLGA with known number-average molecular weight above, and weigh a corresponding amount of PEG with different molecular weights according to the molar ratio of PLGA and PEG of 2:1 (refer to Table 2 for the corresponding matching of PLGA and PEG molecular weight), Add it into a 50mL three-necked flask; wherein, the number-average molecular weight of PEG is 3.7 times that of PLGA, see Table 2 to select and match PLGA (Mn=5411) and PEG (Mn=20000) with gel regions.

[0066] (2) Nitrogen or inert gas was introduced under normal pressure, heated to 110° C. with an electric heating mantle under magnetic stirring, and reacted for 18 hours. Obtain the crude product of PLGA-PEG-PLGA triblock polymer with different molecular weight matching, and cool to room temperature under nitrogen or inert gas atmosphere;

[0067...

Embodiment 3

[0071] The difference between this embodiment and Example 1 is that the steps of synthesizing PLGA-PEG-PLGA copolymer are as follows:

[0072] (1) Weigh a certain amount of PLGA with known number-average molecular weight above, and weigh a corresponding amount of PEG with different molecular weights according to the molar ratio of PLGA and PEG of 2:1 (refer to Table 2 for the corresponding matching of PLGA and PEG molecular weight), Add it into a 50mL three-necked flask; wherein, the number average molecular weight of PEG is 4 times that of PLGA, see Table 2 to select matching PLGA (Mn=2000) and PEG (Mn=8000) with gel regions.

[0073] (2) Nitrogen or inert gas was introduced under normal pressure, heated to 230° C. with an electric heating mantle under magnetic stirring, and reacted for 6 hours. Obtain the crude product of PLGA-PEG-PLGA triblock polymer with different molecular weight matching, and cool to room temperature under nitrogen or inert gas atmosphere;

[0074] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com