Antioxidant packaging film of food and preparation method of packaging film

A packaging film and anti-oxidation technology, which is applied in the field of food anti-oxidation packaging film and its preparation, can solve the problem of not having food preservation, anti-oxidation, antibacterial and other fresh-keeping properties, and achieves extended food shelf life, good processing performance, casting The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

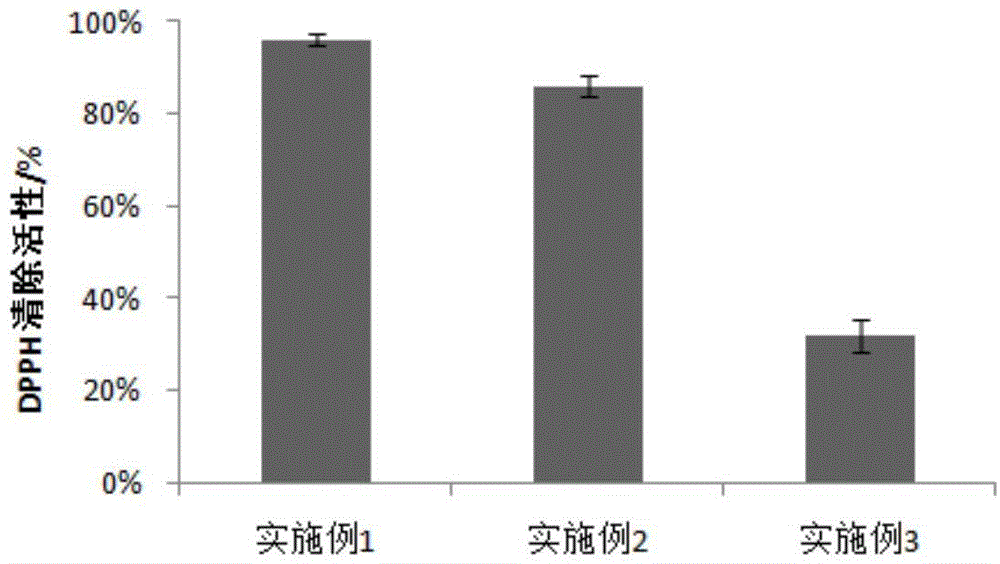

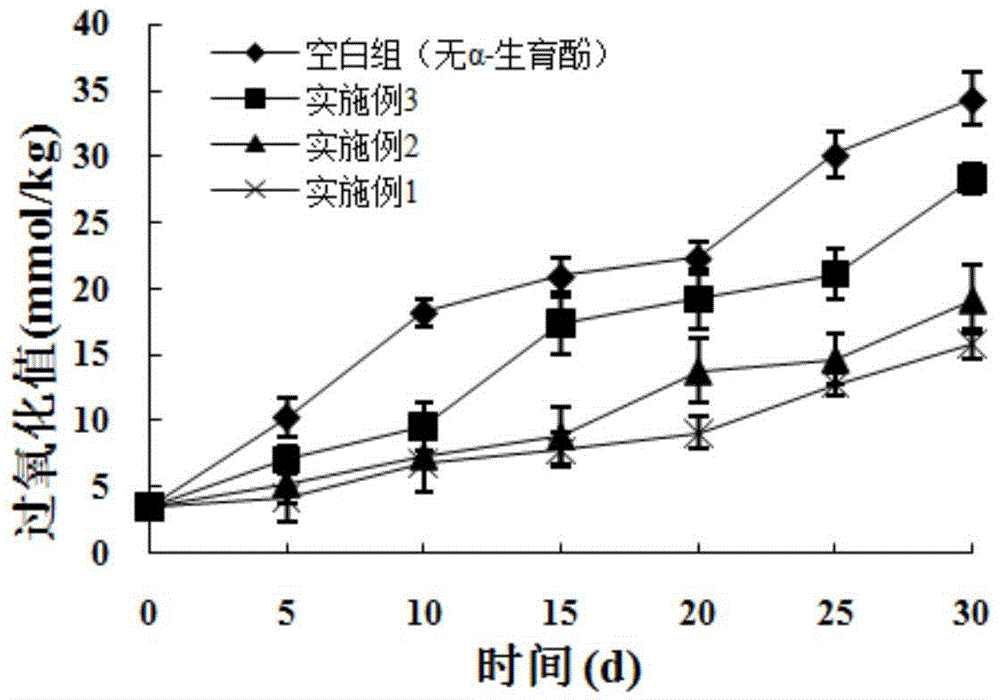

Examples

preparation example Construction

[0019] The preparation method of this EVOH food antioxidant packaging film is as follows:

[0020] (1) Antioxidant solution preparation: take 75% ethanol solution as a solvent, weigh a certain amount of α-tocopherol and dissolve it in the ethanol solution, and prepare an antioxidant solution containing α-tocopherol.

[0021] (2) Membrane solution configuration: First, weigh a certain amount of n-propanol and dissolve it in distilled water, and configure it into an aqueous solution of n-propanol according to the volume ratio of n-propanol and distilled water as 1 to 2; then, weigh a certain amount of n-propanol according to the mass ratio. High-quality EVOH resin, PVA resin and glycerin are added to the prepared n-propanol aqueous solution to form a mixed solution, and the mixed solution is placed in a constant temperature water bath to make it under the condition of 50 ° C ~ 75 ° C Heat and stir until completely dissolved; then, weigh a certain amount of the antioxidant soluti...

Embodiment 1

[0025] (1) Antioxidant solution preparation: take 75% ethanol solution as solvent, weigh 20g of α-tocopherol and dissolve in 20ml of ethanol solution, and prepare an antioxidant solution with α-tocopherol concentration of 1g / ml.

[0026] (2) Membrane liquid configuration: first, configure n-propanol aqueous solution, the volume ratio of n-propanol and distilled water is 1; then, weigh 17.5g EVOH resin, 3.75g PVA resin and 1.25g glycerol, add it to 350ml n-propanol Propanol aqueous solution, then put the mixed solution into a constant temperature water bath, heat and stir at 50°C to 75°C until completely dissolved; then, add the α-tocopherol prepared in step (1) to the mixed solution Solution 2.5ml, continue to stir until a homogeneous film-forming solution is obtained.

[0027] (3) Film formation: put the film-making solution prepared in step (2) into a vacuum drying oven to remove the air bubbles in the solution, and then use a syringe to draw a certain volume of film liquid ...

Embodiment 2

[0029] (1) Antioxidant solution preparation: take 75% ethanol solution as solvent, weigh 20g of α-tocopherol and dissolve in 20ml of ethanol solution, and prepare an antioxidant solution with α-tocopherol concentration of 1g / ml.

[0030] (2) Membrane solution configuration: First, configure n-propanol aqueous solution, the volume ratio of n-propanol to distilled water is 2; then, weigh 20g EVOH resin, 2.75g PVA resin and 0.25g glycerol, add it to 300ml n-propanol Alcohol aqueous solution, then put the mixed solution into a constant temperature water bath, heat and stir at 50°C to 75°C until completely dissolved; then, add the α-tocopherol solution prepared in step (1) to the mixed solution 2ml, continue to stir until a homogeneous film-forming solution is obtained.

[0031] (3) Film formation: put the film-making solution prepared in step (2) into a vacuum drying oven to remove the air bubbles in the solution, and then use a syringe to draw a certain volume of film liquid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com