Composite enhanced high-flexibility microporous silicone rubber foam material and preparation method thereof

A foam material and composite reinforcement technology are applied in the field of composite reinforced high-flexibility microporous silicone rubber foam materials and their preparation, which can solve the tedious work, requiring two times to complete, poor wear resistance of foam materials, and low material resilience. and other problems, to achieve the effects of excellent comprehensive performance, improved softness and wear resistance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

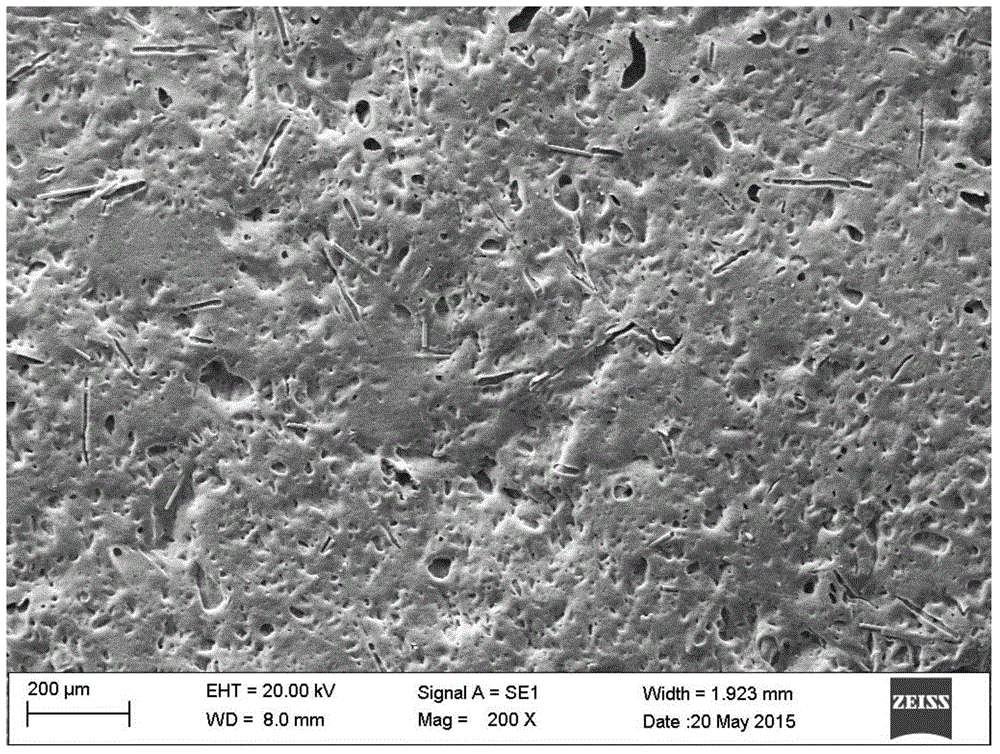

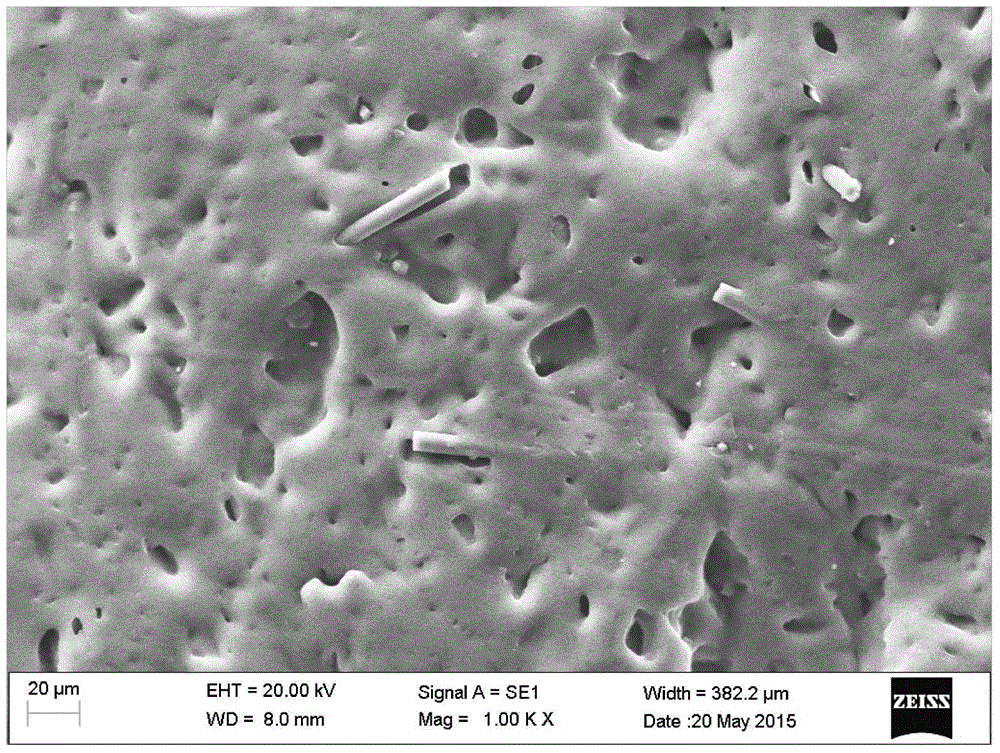

[0041] Step 1. Add 100g of methyl vinyl silicone rubber base material with a vinyl content of 0.1mol% into a two-roll mill, masticate at 60°C for 5 minutes, then add 15g of fumed silica and 5g of carbon fiber, 1g of silane coupling agent KH550, 2.5mL of hydroxy silicone oil, mixed for 5 minutes, then added 80g of ammonium carbonate, 5g of triallyl cyanurate, 1g of chitin, and continued to mix for 5 minutes to obtain rubber, and then The preliminary mixed rubber material was stored statically for 30 hours, and then the rubber material was re-mixed at 60°C for 8 minutes. At room temperature, the mixed rubber material was molded into a sheet or block on a tablet press; The drum speed of the two-roll mill is set to 300r.min -1 ; The ammonium carbonate is ground before use to obtain particles with a particle size of 200 μm;

[0042] Step 2. After the formed sheet or block is plastic-sealed, place it in the air at room temperature 60 Radiation cross-linking is carried out in the C...

Embodiment 2

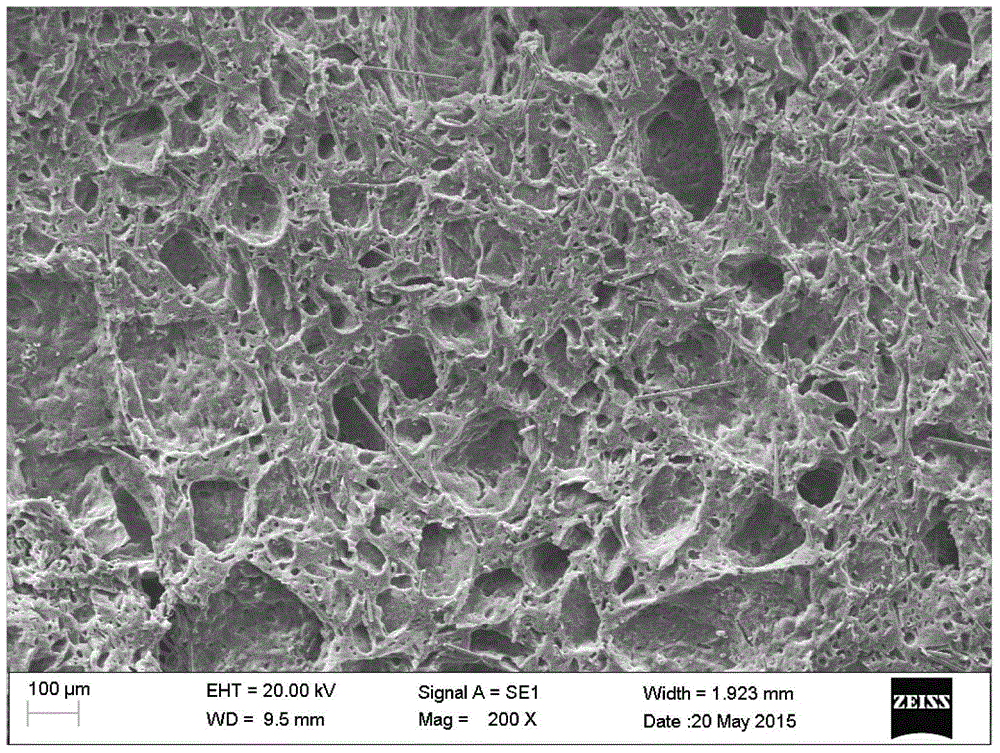

[0045] Step 1. Add 100g of methyl vinyl silicone rubber base material with a vinyl content of 0.1mol% into a two-roll mill, masticate at 50°C for 3 minutes, then add 5g of precipitated silica and 5g of carbon fiber, 2g silane coupling agent KH560, 2mL hexamethyldisilazane, knead for 5 minutes, then add 90g ammonium carbonate, 3g triallyl cyanurate, 1g chitin, 1g magnesium hydroxide, continue kneading for 5 Minutes to get the rubber material, and then store the rubber material after preliminary mixing for 30 hours, and then re-mix the rubber material at 50°C for 8 minutes, and mold the mixed rubber material on a tablet press at room temperature Formed into sheets or blocks; the rotary drum speed of the two-roll mill is set to 500r.min -1 ; The ammonium carbonate is ground before use to obtain particles with a particle size of 300 μm;

[0046] Step 2. After the formed sheet or block is plastic-sealed, place it in the air at room temperature 60 Radiation cross-linking is carrie...

Embodiment 3

[0049] Step 1. Add 100g of methyl vinyl silicone rubber base material with a vinyl content of 0.11mol% into a two-roll mill, masticate at 50°C for 5 minutes, then add 15g of precipitated silica and 10g of carbon fiber, 2g titanate CB-401, 2.5mL cyclic trisilazane, knead for 5 minutes, then add 80g ammonium chloride, 3g-1,6-hexanediol diacrylate, 1g chitin, 1g magnesium hydroxide , 1g of dihydroquinoline, and continue mixing for 4 minutes to obtain a rubber compound, then statically store the initially mixed rubber compound for 35 hours, then re-mix the rubber compound for 8 minutes at 50°C, and at room temperature, place the The rubber material that has been mixed is molded into a sheet or a block on a tablet press; the rotating drum speed of the two-roll mill is set to 400r.min -1 ; The ammonium chloride is ground before use to obtain particles with a particle size of 200 μm;

[0050] Step 2. After the formed sheet or block is plastic-sealed, place it in the air at room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com