Curcumin derivative preparing method

A technology of curcumin derivatives and curcumin, which is applied in the field of preparation of curcumin derivatives, and can solve the problems of poor absorption ability, curcumin's long-lasting efficacy, low selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

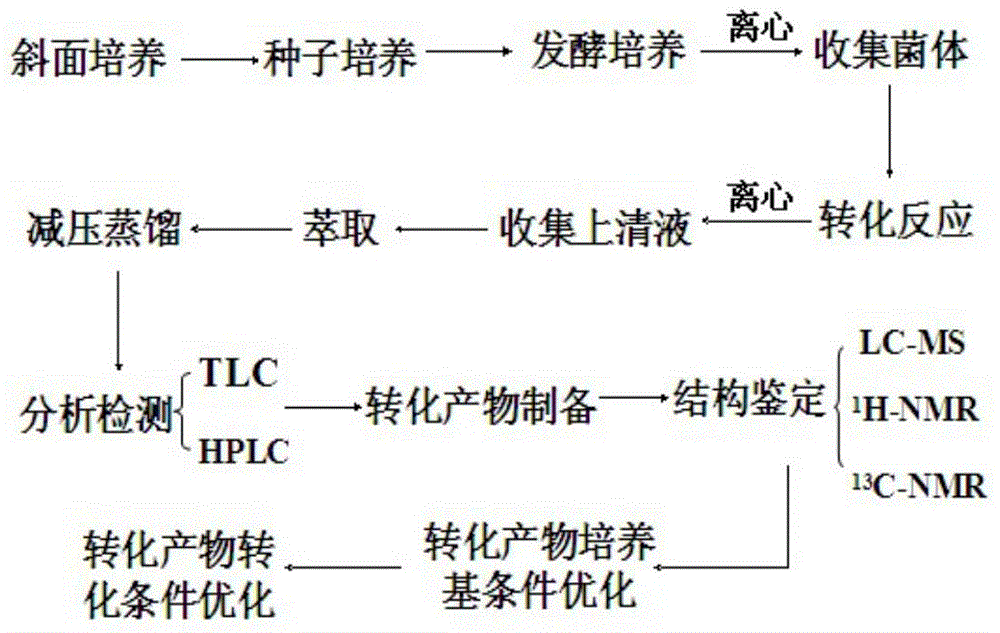

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the preparation of curcumin transformation product

[0039] (1) Slant culture: inoculate Rhodococcus ZJPH1003 into the slant medium, and cultivate at 30°C for 3 to 4 days to obtain slant strains; the final concentration of the slant medium consists of: glucose 10g / L, peptone 5.0g / L , yeast extract 3.0g / L, (NH 4 ) 2 SO 4 4.0g / L,KH 2 PO 4 1.0g / L, K 2 HPO 4 1.0g / L, MgSO 4 ·7H 2 O 0.5g / L, NaCl 0.5g / L, agar 30g / L, solvent is water, pH 7.0, sterilized at 121°C for 20 minutes, cooled after sterilization, and made into a slope;

[0040] (2) Seed culture: pick a ring of thalli from the slant of step (1) and inoculate it into a 250mL shake flask equipped with 100mL seed medium, cultivate at 30°C and 200rpm for 24h, and prepare a seed solution; the seed culture The base final concentration is composed of: glucose 10g / L, peptone 5.0g / L, yeast extract 3.0g / L, (NH 4 ) 2 SO 44.0g / L,KH 2 PO 4 1.0g / L, K 2 HPO 4 1.0g / L, MgSO 4 ·7H 2 O 0.5g / L, NaCl 0.5g / L, ...

Embodiment 2~7

[0066] The effect of embodiment 2~7 thalline concentration on the transformation preparation product 4 of Rhodococcus ZJPH1003

[0067] Utilize Rhodococcus sp. (Rhodococcus sp.) ZJPH1003 bacterial strain, after the method for fermenting and cultivating by embodiment 1 step (4), wet thallus is added in the 50mL Erlenmeyer flask that 10mL 0.1M, pH 6.6 phosphate buffer are housed (wet bacteria Body is respectively 14.4g / L, 21.6g / L, 28.9g / L, 36.1g / L, 43.3g / L, 50.5g / L) (shown in table 2) with thalline dry weight, substrate curcumin The final concentration was 50mg / L, and the transformation was carried out at 30°C and 200rpm for 36h. After the reaction, the transformed liquid was centrifuged to remove the bacteria to obtain a supernatant, which was extracted three times with ethyl acetate, combined with the extracts, concentrated to dryness at 50°C under reduced pressure, and the residue obtained after rotary evaporation was then used in 0.75ml The chromatographic methanol was re-d...

Embodiment 8~14

[0071] Examples 8-14 Effect of the pH value of the transformation solution on the transformation of Rhodococcus ZJPH1003 to produce product 4

[0072] Utilize Rhodococcus sp. (Rhodococcus sp.) ZJPH1003 bacterial strain, after fermenting and cultivating according to the method of step (4) of Example 1, add the wet thalline into 10mL 0.1M, pH is respectively 5.4~8.0 phosphate buffer (Table 3) Shown) in the 50mL Erlenmeyer flask (wet thalline final concentration is 43.3g / L), substrate curcumin concentration is 50mg / L, at 30 ℃, 200rpm transformation 36h. After the reaction was over, the cells were removed by centrifugation to obtain the supernatant, which was extracted three times with ethyl acetate, the extracts were combined, concentrated under reduced pressure to dryness to remove ethyl acetate, and the residue obtained after rotary evaporation was then washed with 0.75ml chromatographic methanol After re-dissolving, the detection method is the same as that in step (7) of Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com